A method of solid waste gasification power generation

A technology for solid waste and gas generators, which is applied in the direction of gasification process, gaseous engine fuel, engine components, etc. It can solve the problems of poor heat recovery effect, inability to recover heat from multiple angles, and achieve convenient insertion installation and recovery effects Good and efficient recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

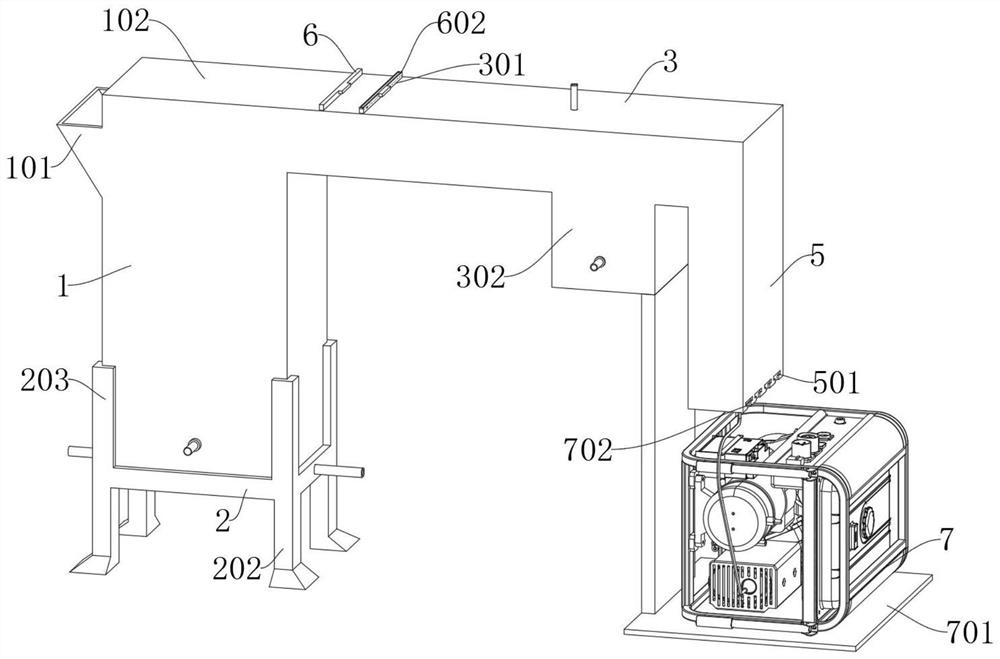

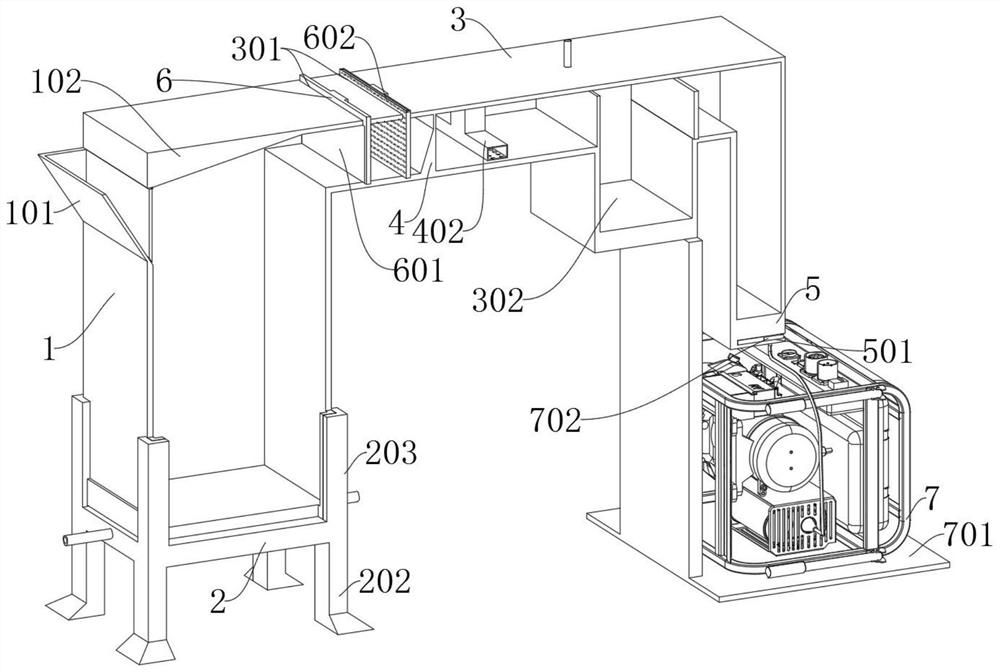

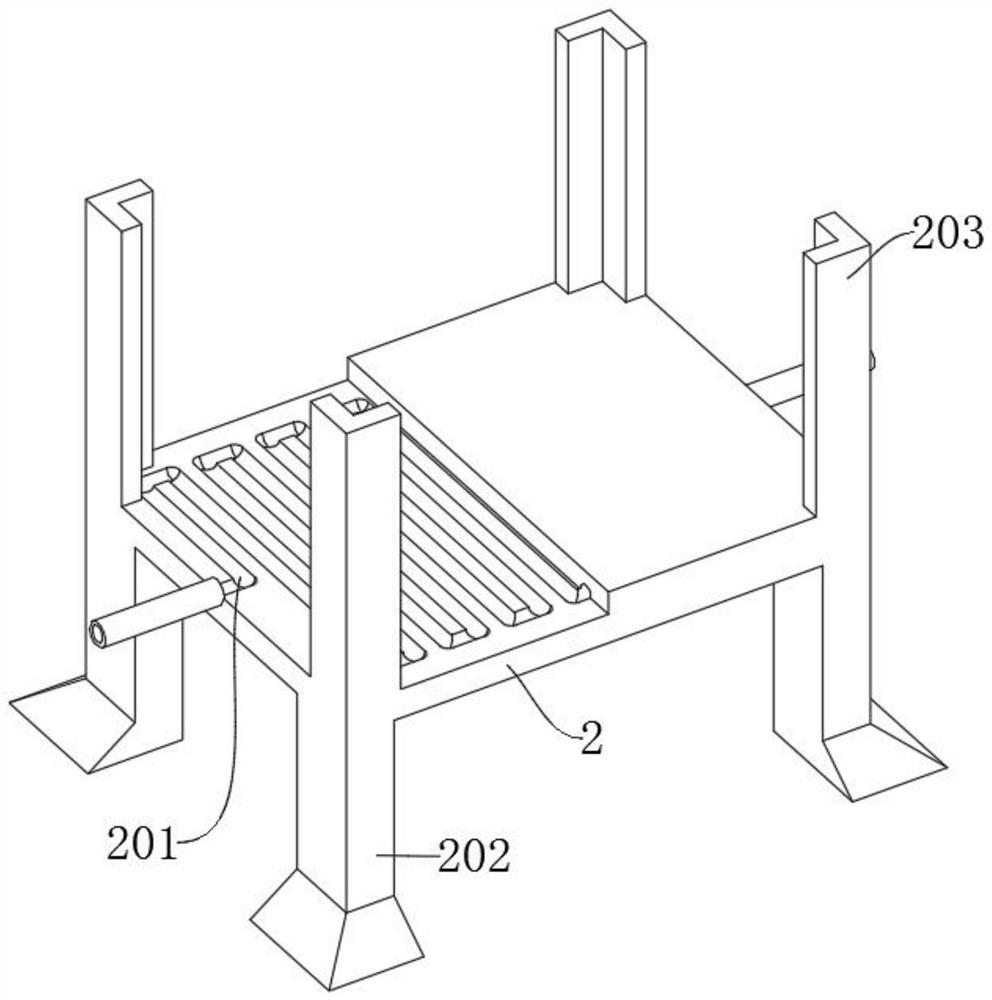

[0038] as attached figure 1 to attach Figure 8 Shown:

[0039] The present invention provides a solid waste gasification power generation method. The solid waste gasification power generation method is completed by a solid waste gasification power generation device, which specifically includes the following steps:

[0040] S1 first place the bottom part 2 in an appropriate position, then install the main body 1 by manpower control, so that the bottom of the main body 1 can be inserted into the inside of the fixing part 203, then make the main body 1 contact with the top of the bottom part 2, and then put the two The water inlet pipe is connected with the main body 1 and the water inlet pipe of the bottom part 2, and then the two water outlet pipes are connected with the main body 1 and the water outlet pipes of the bottom part 2;

[0041] S2 then the gas generator 7 is placed on the top of the receiving plate 701, then the water inlet pipe is connected to the top of the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com