Patents

Literature

31results about How to "There will be no gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

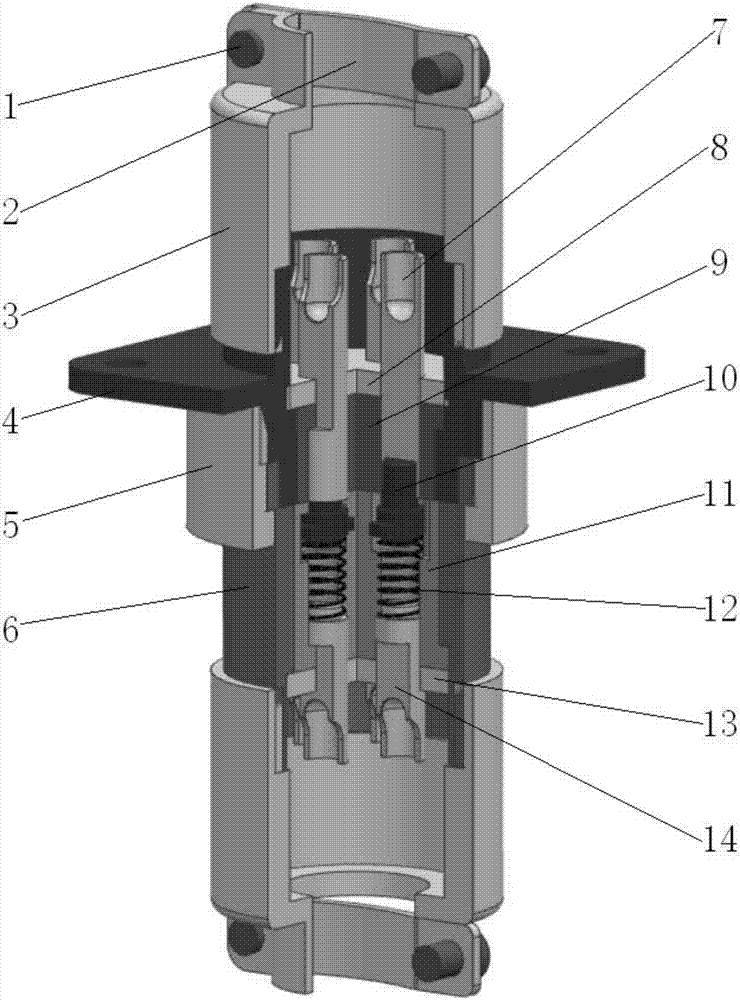

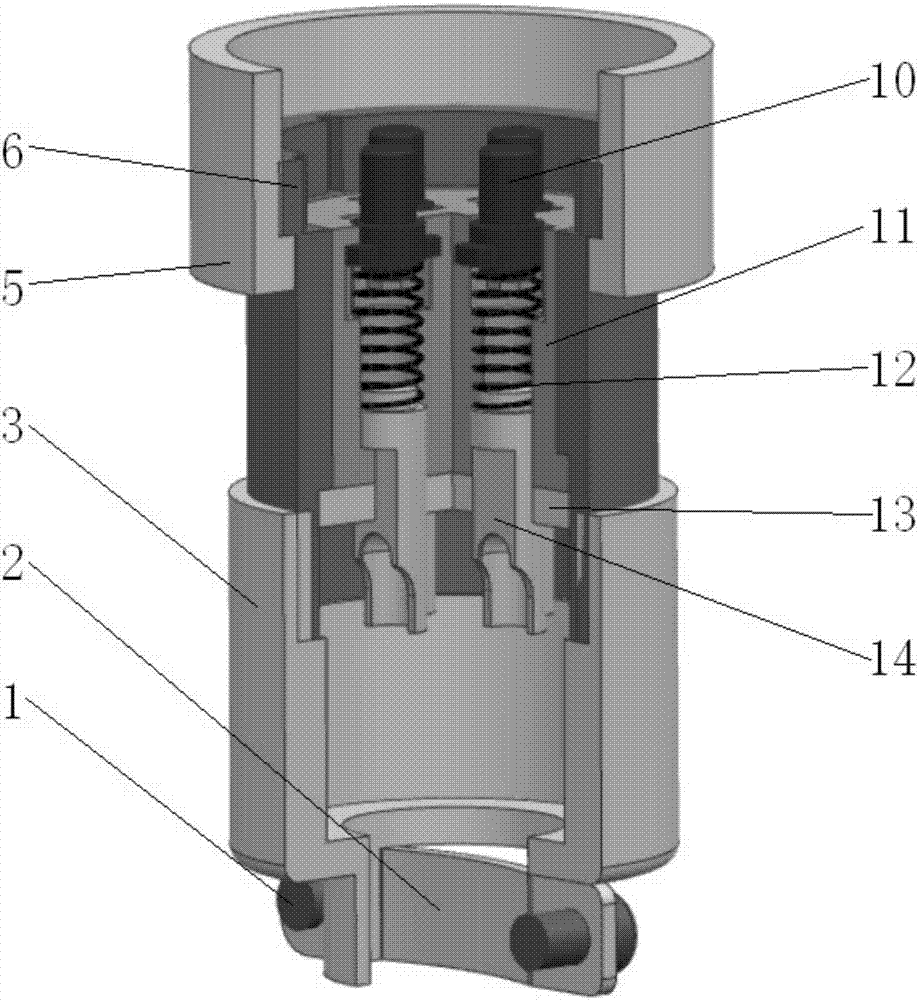

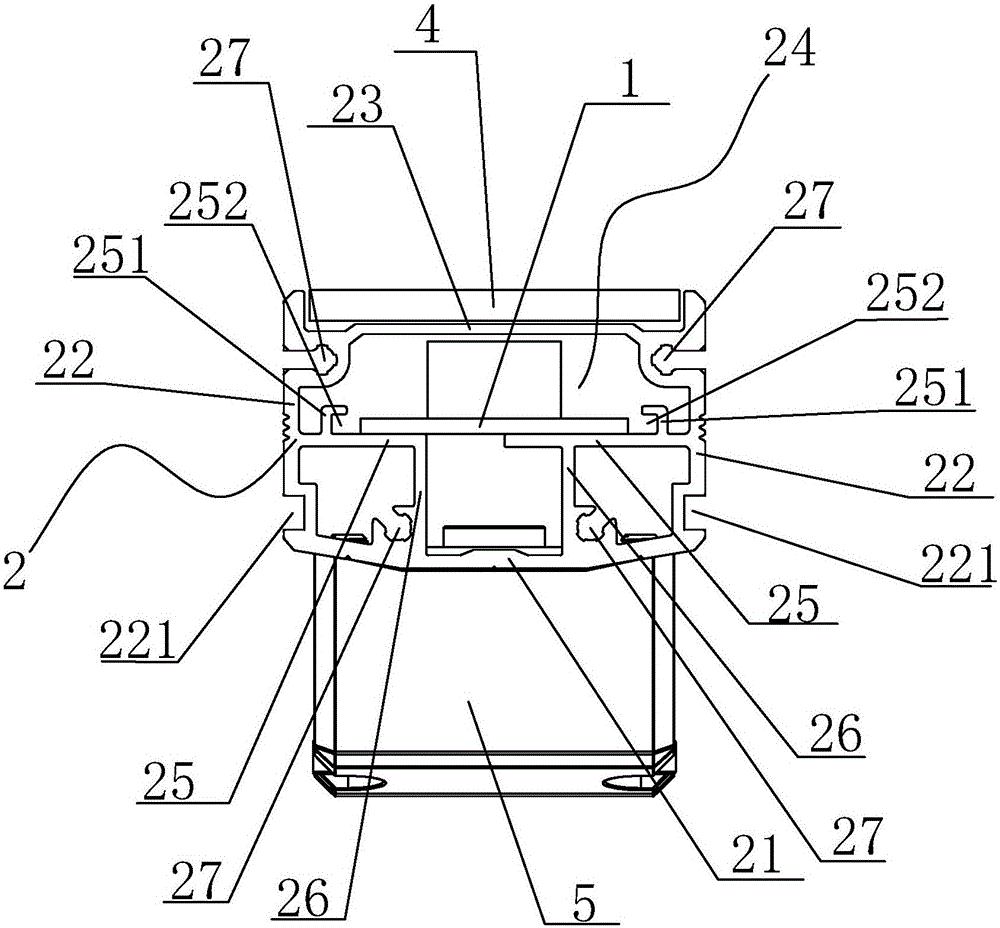

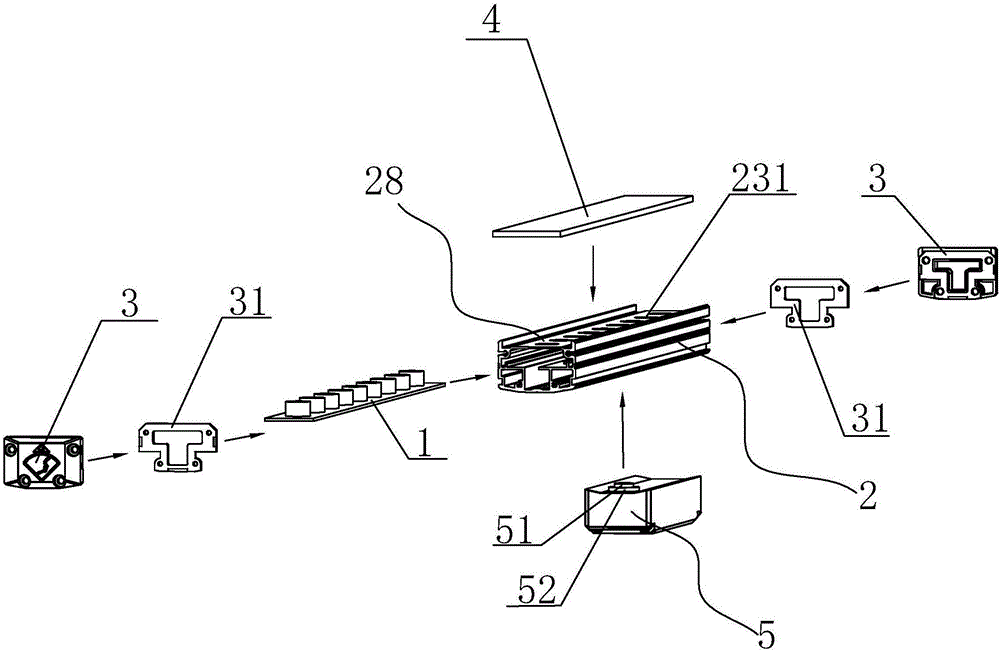

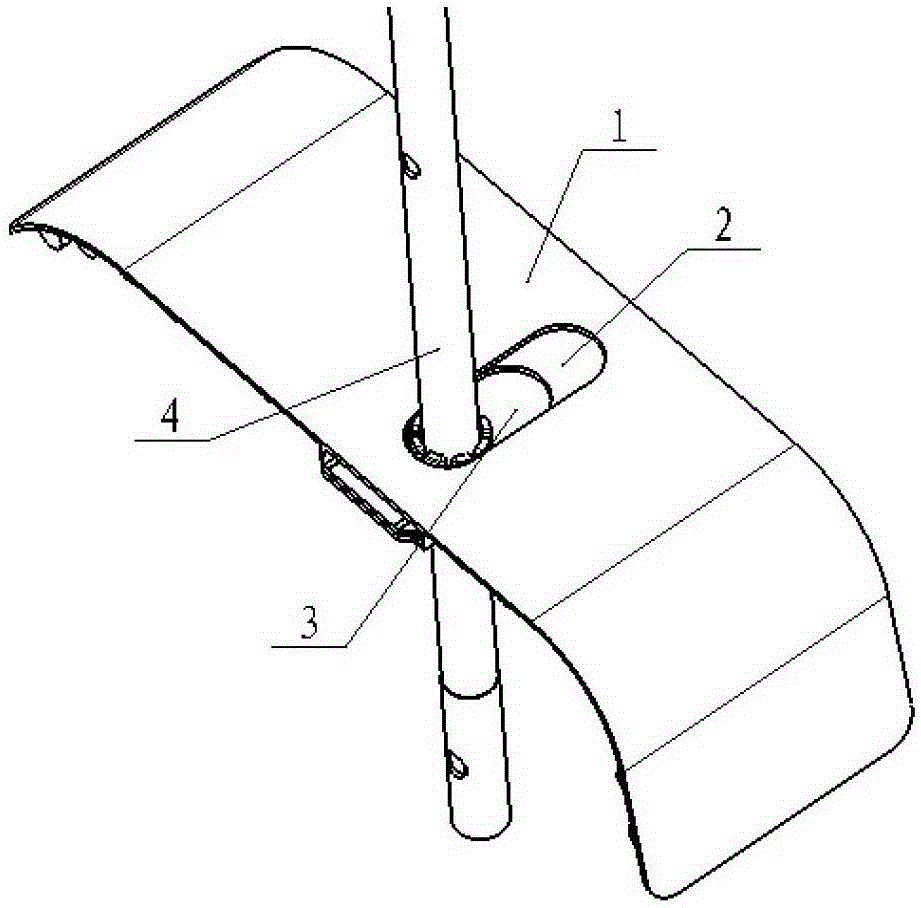

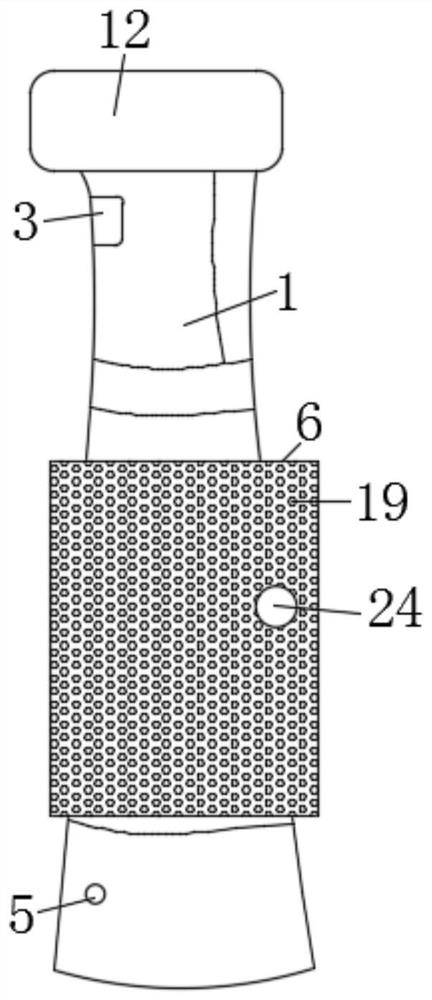

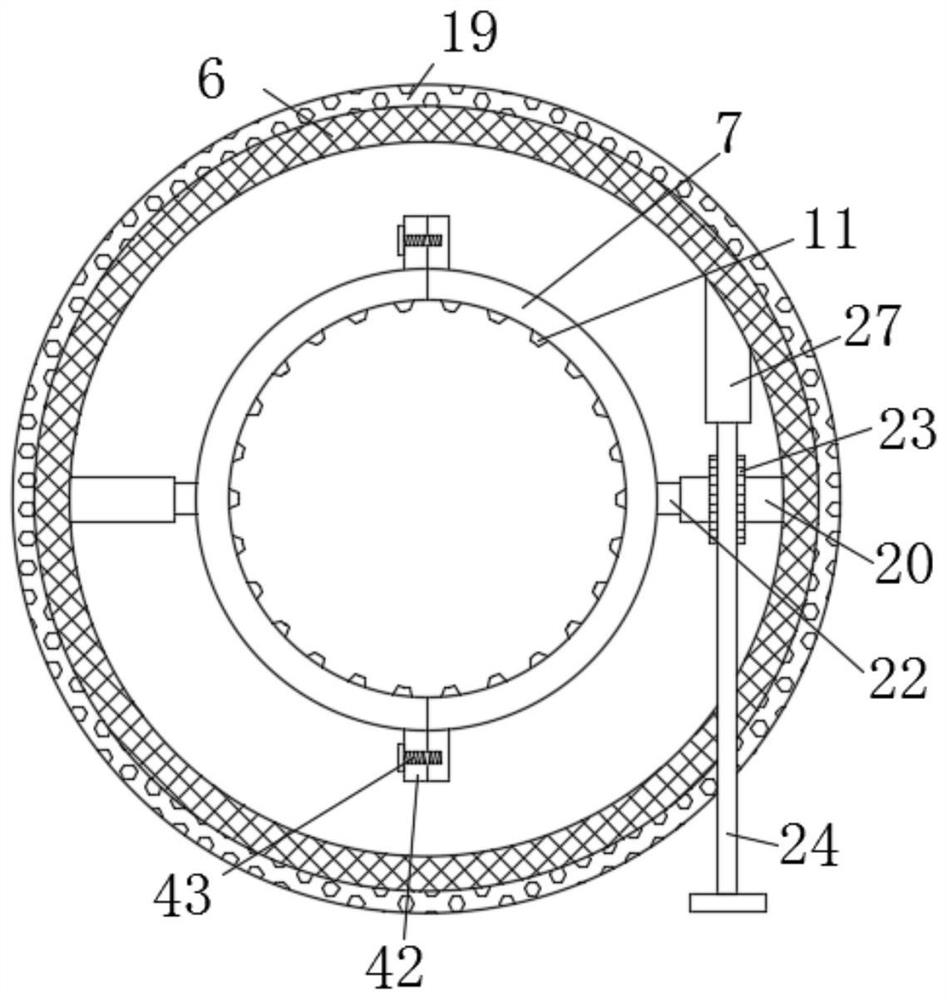

Elastic collision type sealed electric plug

ActiveCN107230858AReliable contactThere will be no gapsCoupling contact membersCouplings bases/casesElastic collisionContactor

The invention discloses an elastic collision type sealed electric plug, and aims to solve the problem that the existing air plug is powered on by means of pin connection, a female head is contacted with a male head by a tubular piece which is separated into two valves, thus the elasticity is relatively week, when the plug is plugged for many times, poor contact is caused, and the poor contact is random. The invention designs a novel elastic collision type sealed electric plug which is supported by a spring and the end face is contacted and conducted (especially a round end face is contacted and conducted). The electric plug is composed of a fixed plug and a movable plug; and contact devices of the fixed plug and the movable plug carry out reliable surface contact under the counterforce of a compression spring to complete a conductive function. In the elastic collision type sealed electric plug provided by the invention, the movable plug adopts the compression spring to support a touch head; when the fixed plug and the movable plug are connected and tightened, a part of the touch head beyond the contact end face of a moveable guide sleeve is inserted to a round hole of a fixed plug pin, and a cylindrical end face of the touch head is contacted with the bottom surface of the round hole of the fixed plug pin.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

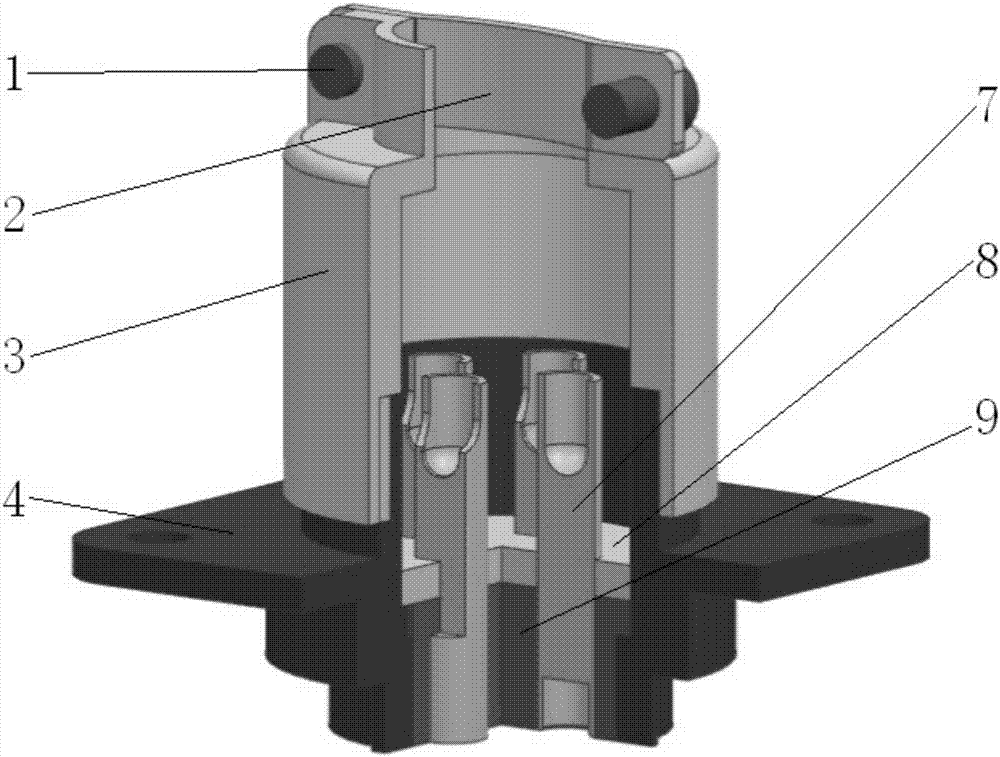

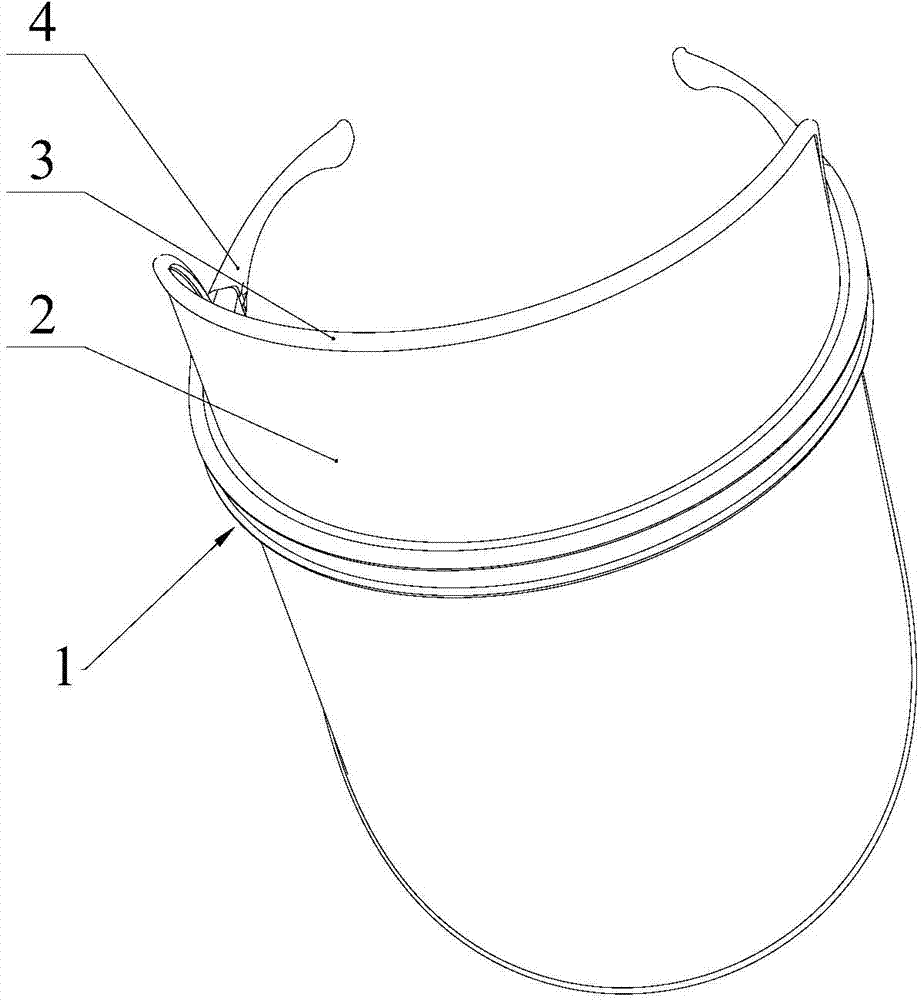

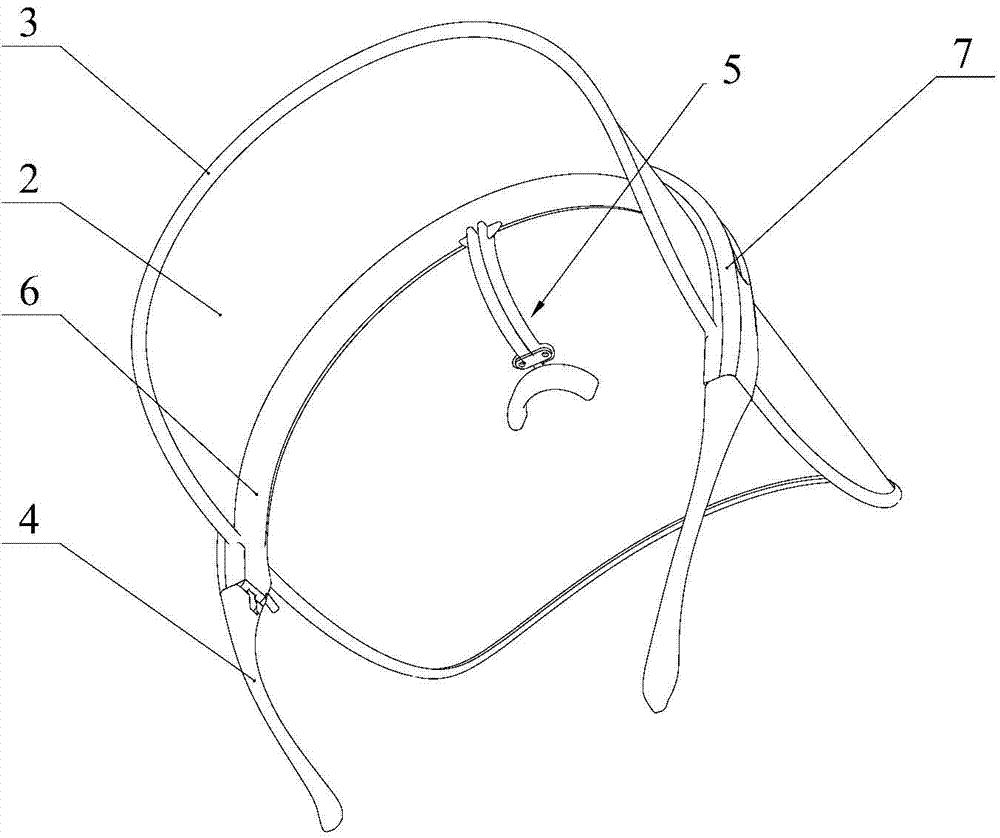

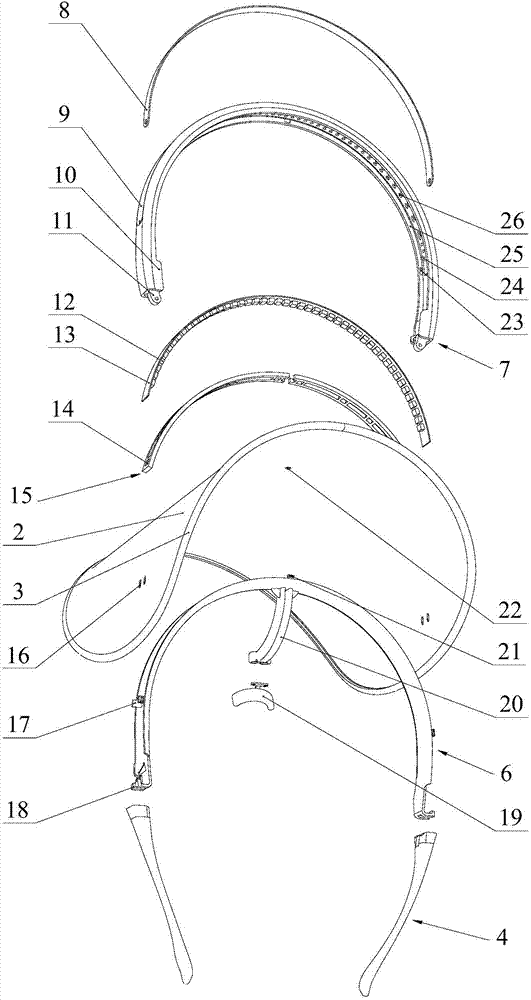

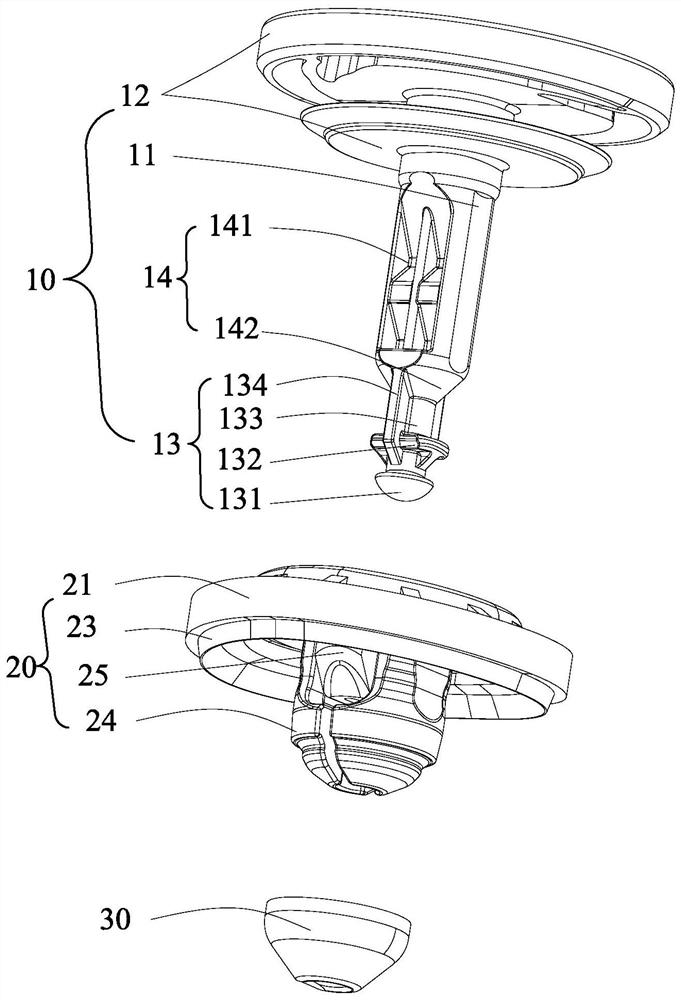

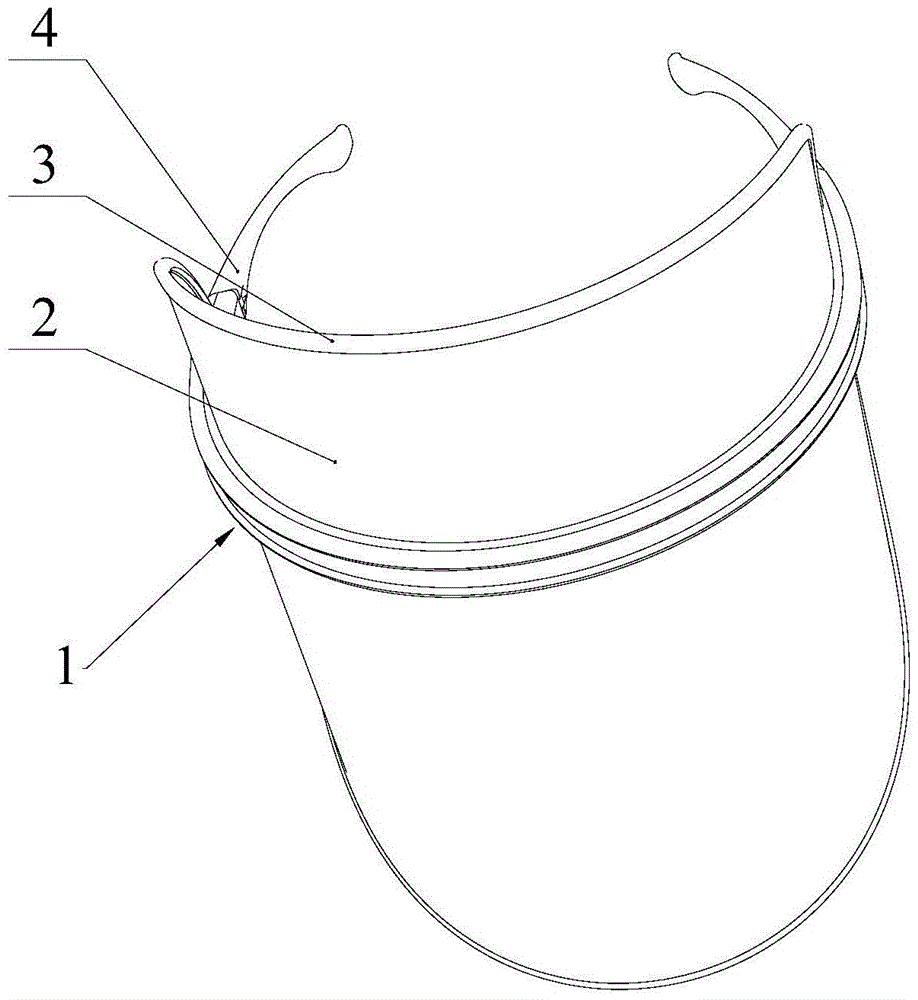

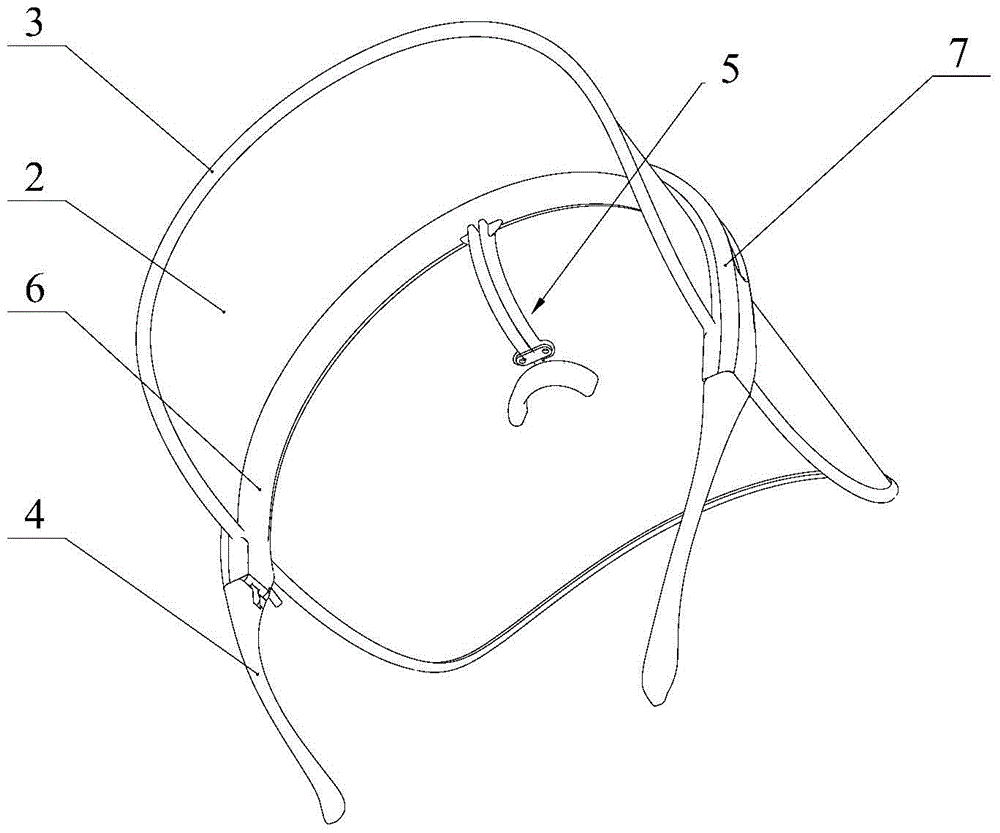

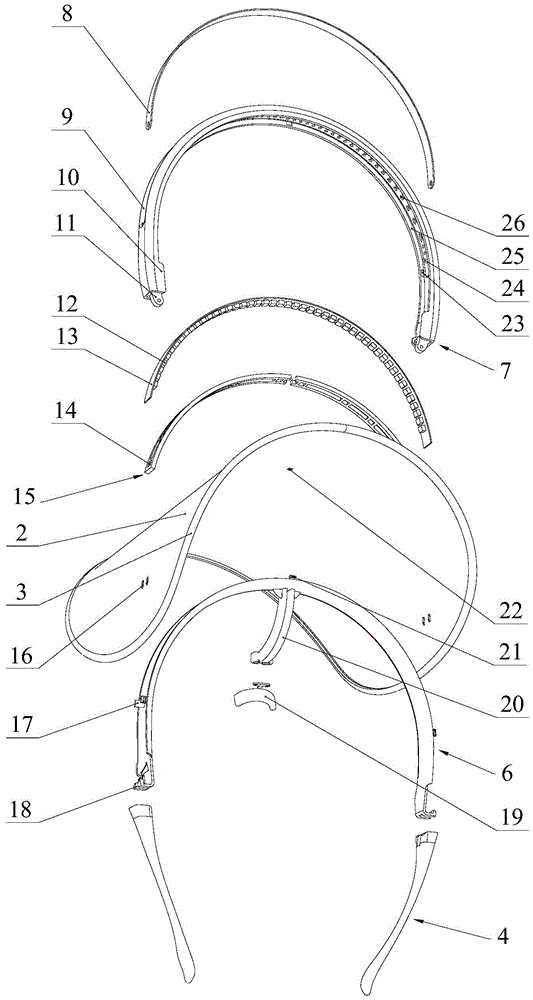

Light-emitting mask

The invention discloses a light-emitting mask comprising a light-emitting component and a mask body and further comprising a framework and ear hooks installed on the framework, wherein the mask body is a light guide board fixed to the framework; the light-emitting component is installed on the framework; the light-emitting component corresponds to the light guide point on the light guide board; the framework comprises an inner frame and an outer frame which are buckled with each other; the light guide board is fixed between the inner frame and the outer frame. The light guide board can cover the whole face, only a strip-shaped framework part of the whole light guide board is shielded, the shielded part of the light guide board is the eye part of the user, and the user experience is good; the light guide board does not make direct contact with the face, frequent cleaning is not required, use is convenient and rapid, and sanitation is achieved; heat is diffused out through cooling holes and cooling fins; the whole outer frame and the light guide board can be better attached to each other through a pressing strip, the sealing performance is better, gaps are avoided, light is not leaked easily, and water or dust does not enter the light-emitting mask easily.

Owner:SHANGHAI HONGYE PHOTOELECTRIC TRADING

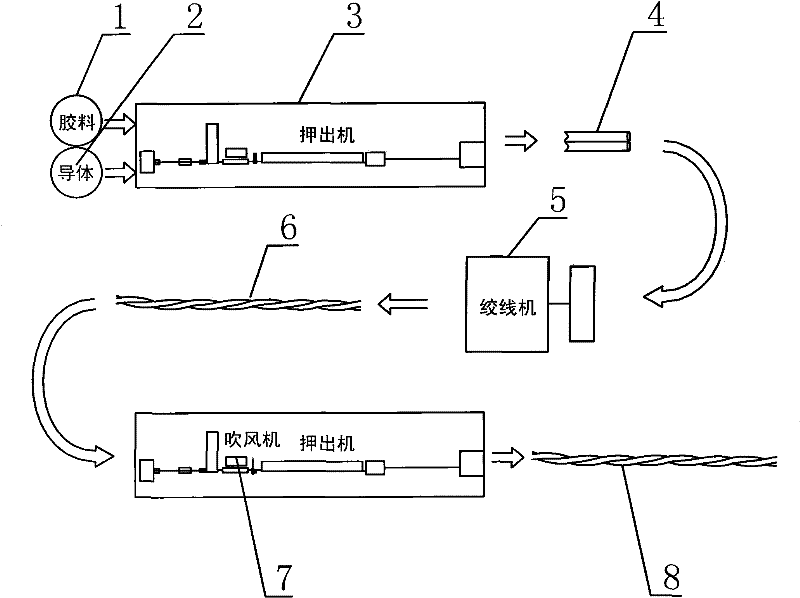

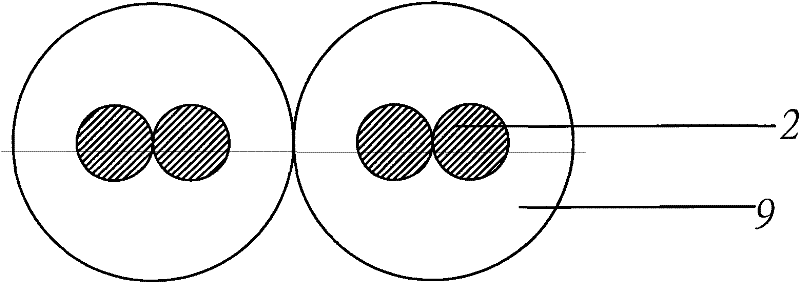

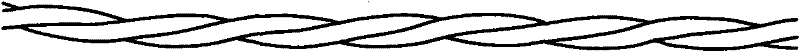

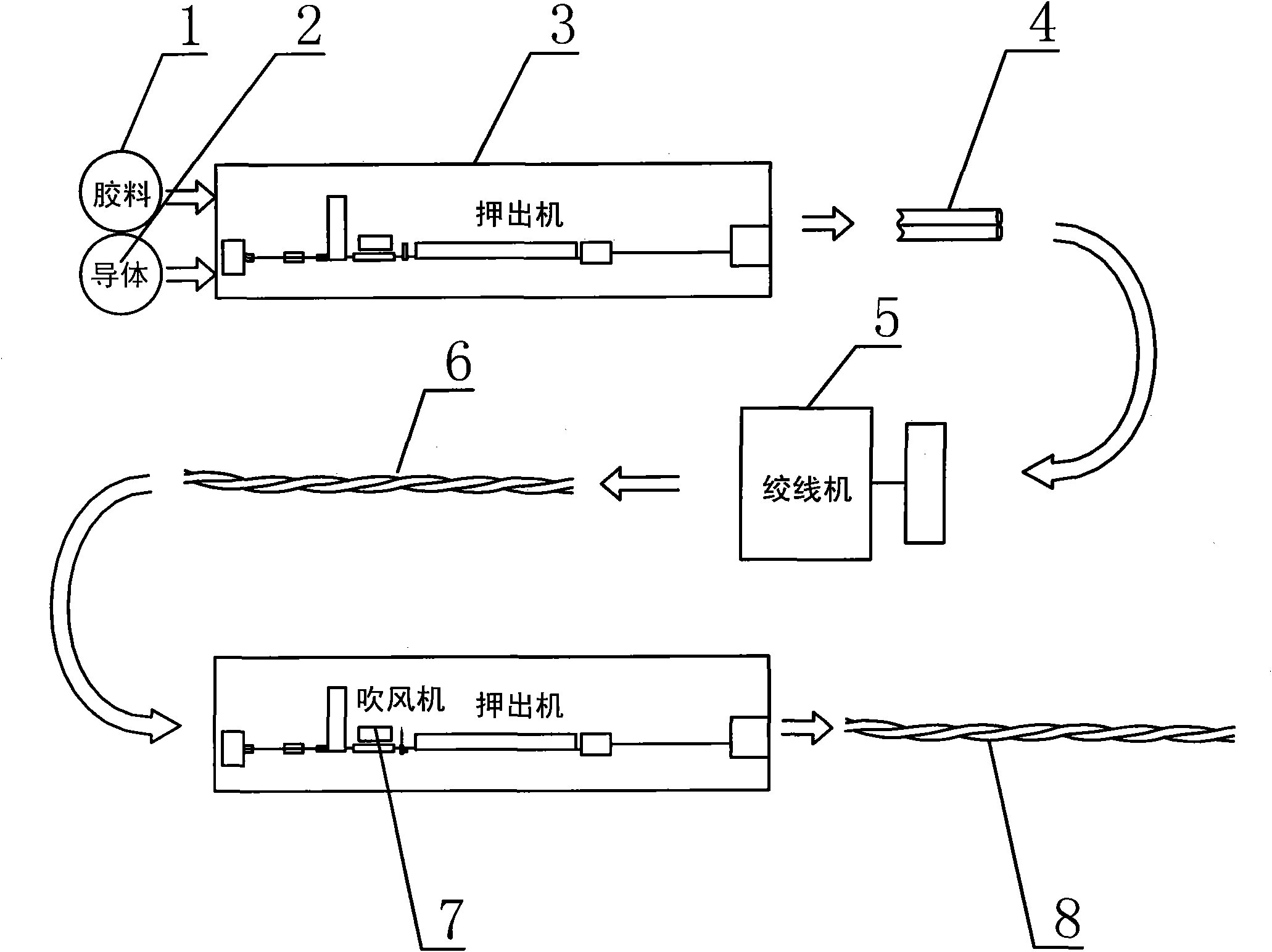

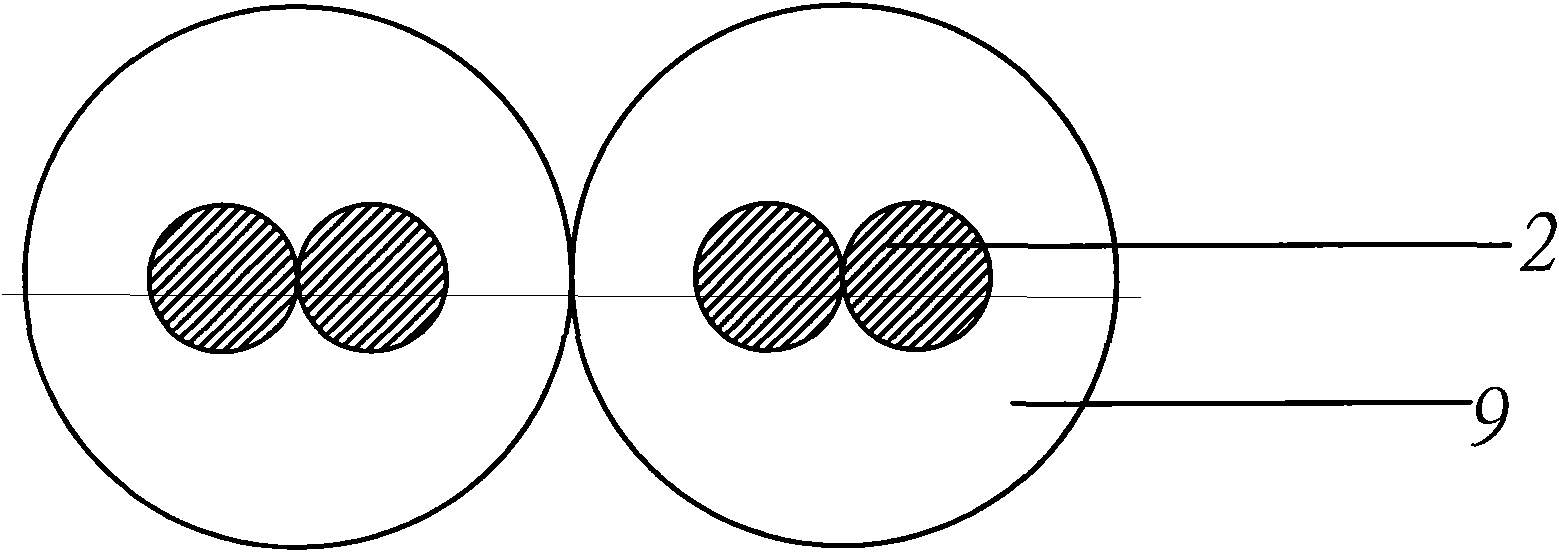

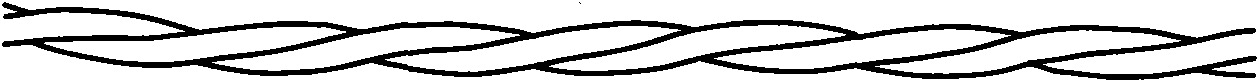

Industrial production method of stranded earphone cord

ActiveCN102222549ANo dispersalThere will be no gapsCable/conductor manufactureEngineeringMethods of production

The invention relates to an industrial production method of a stranded earphone cord, which is characterized by comprising the following production steps: (1) doubling and extruding; a two-earphone-cord combining wire pasted by a coating layer is produced by an extrusion machine; (2) twisting: the produced combining wire is twisted by a wire twisting machine; and (3) heating setting; the twisted wire is heated and set through a high-temperature area. The earphone cords can not be dispersed from two ends after being twisted, dispersion phenomenon can not happen after segmentation, and the phenomenon of generation of a gap between the double cords at the bending part of the earphone wire can not happen, therefore, remarkable effect is achieved owning to the new process of doubling and extruding; besides, the stress of the stranded wire is eliminated after high-temperature setting, and self-winding phenomenon can not happen, therefore, the production efficiency and finished product ratioare greatly improved and the product performance is greatly improved.

Owner:HUBEI YINGTONG ELECTRONICS

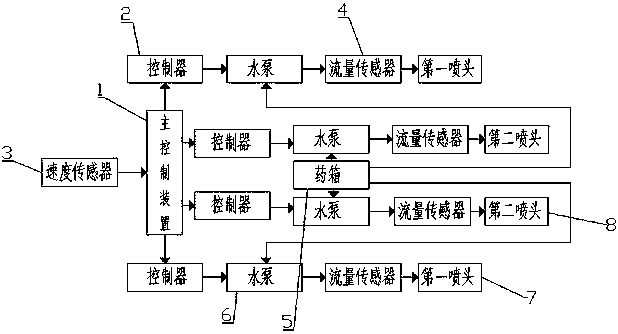

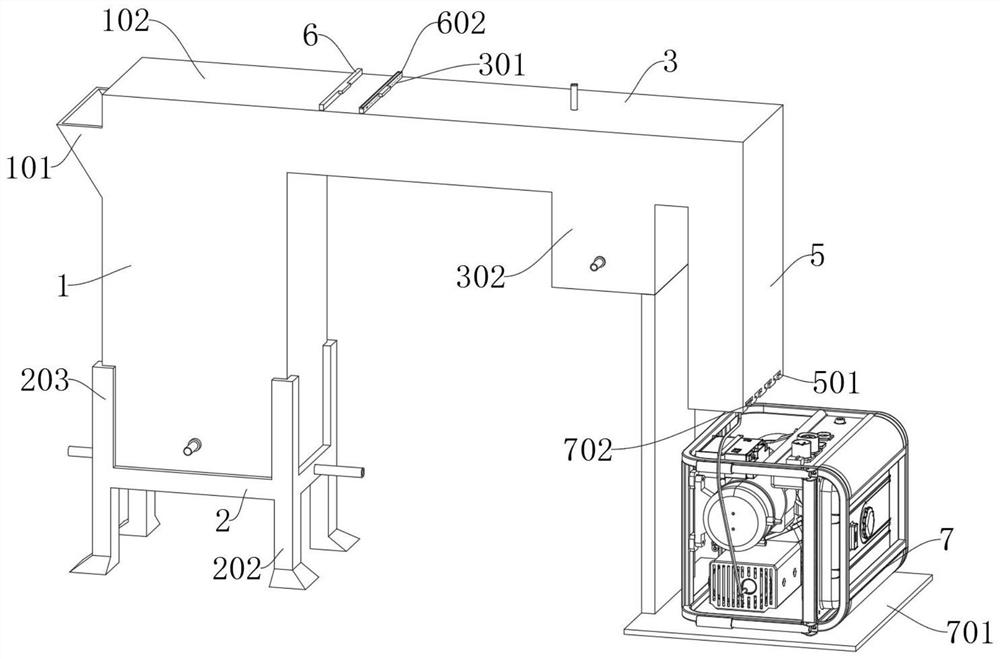

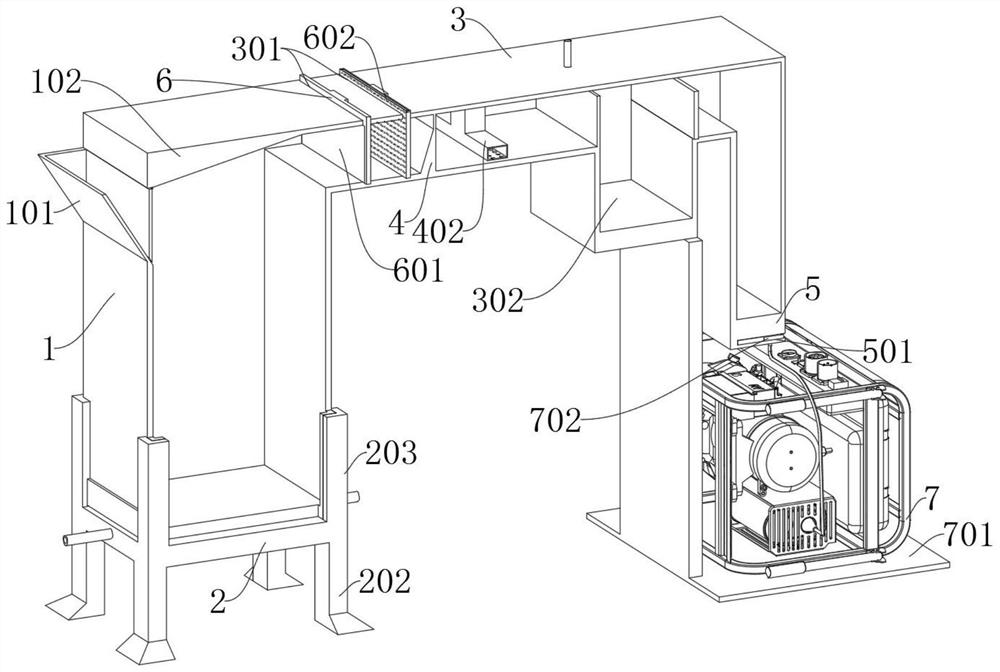

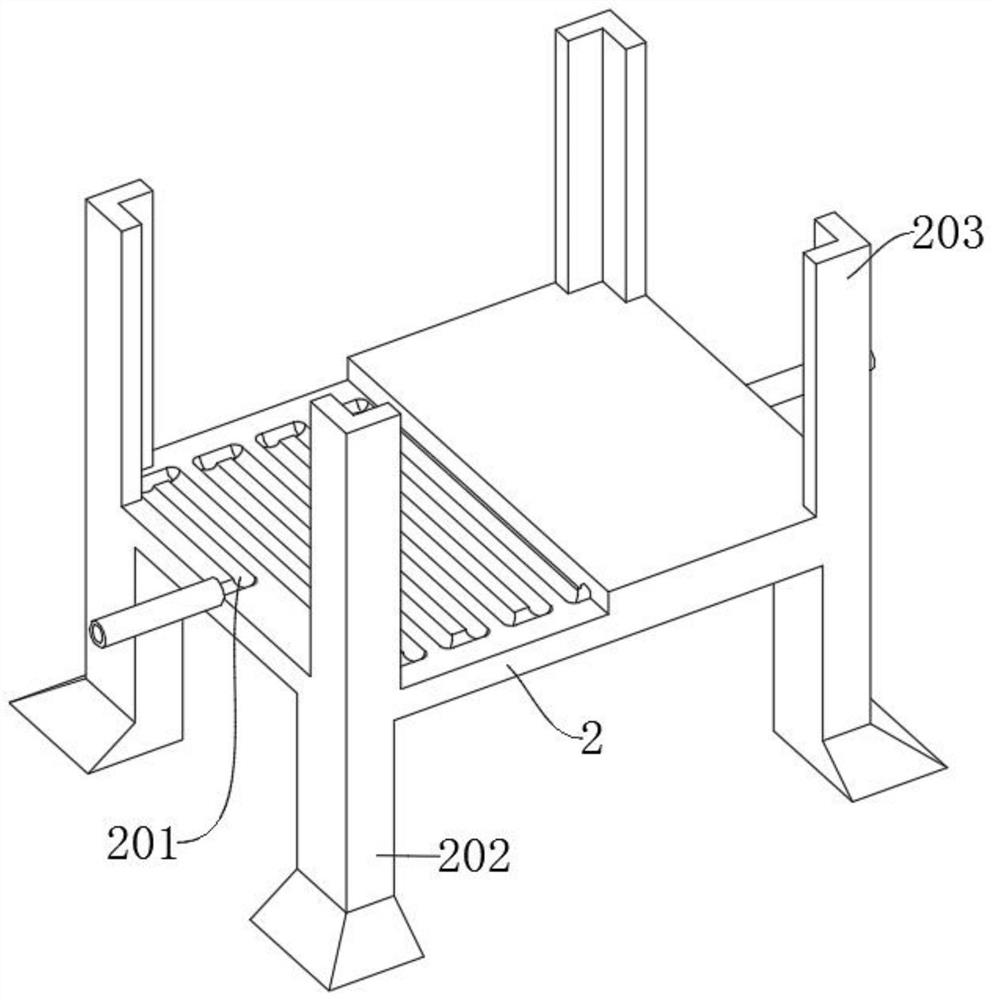

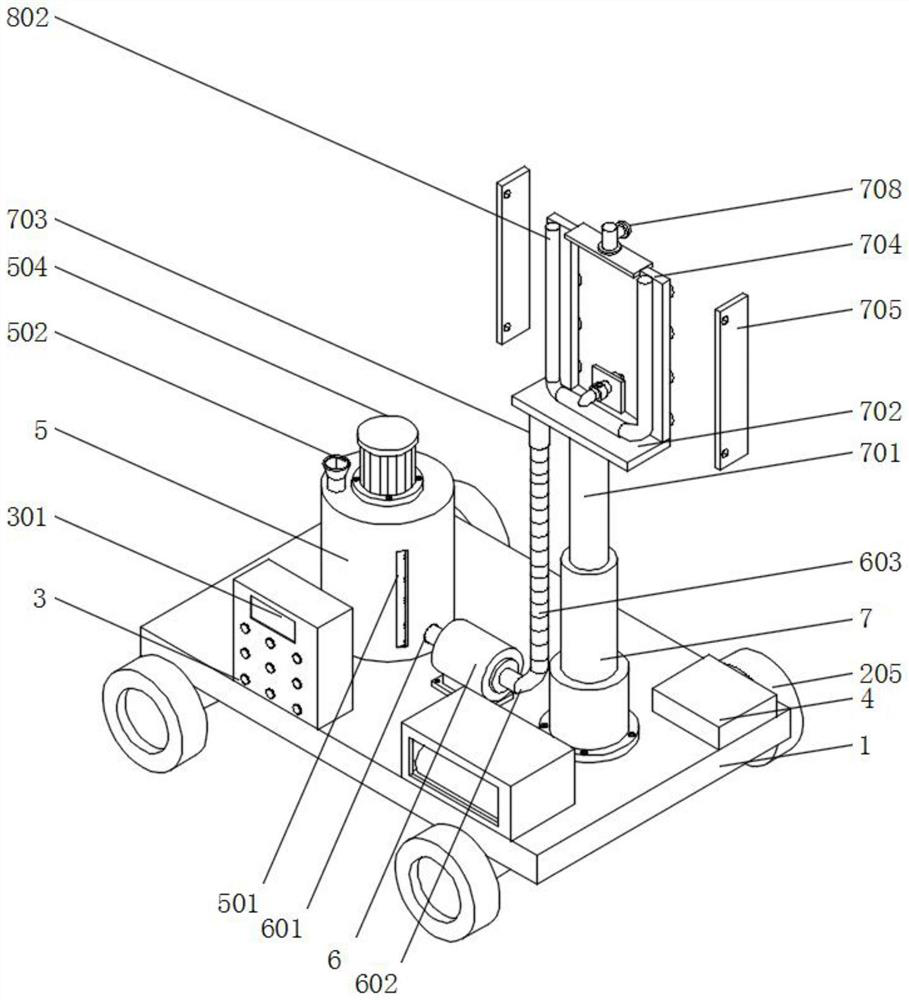

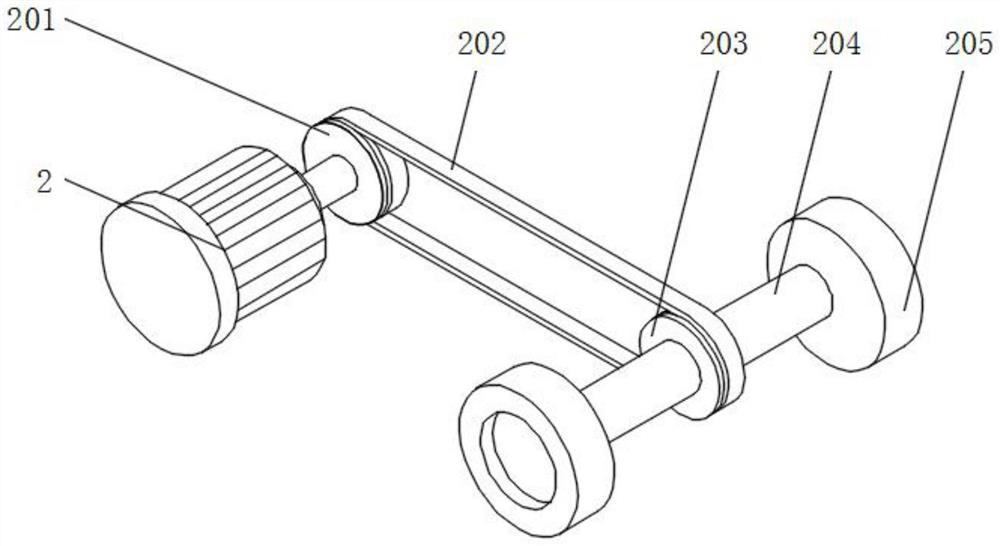

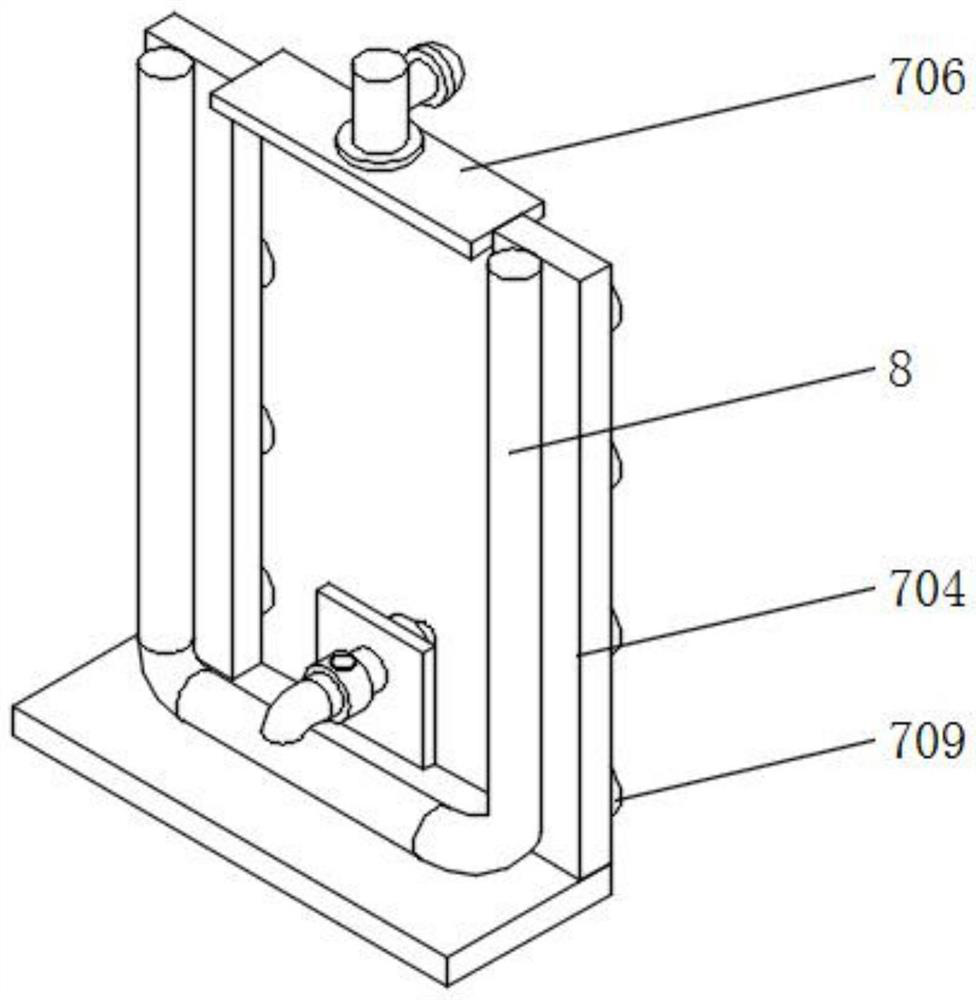

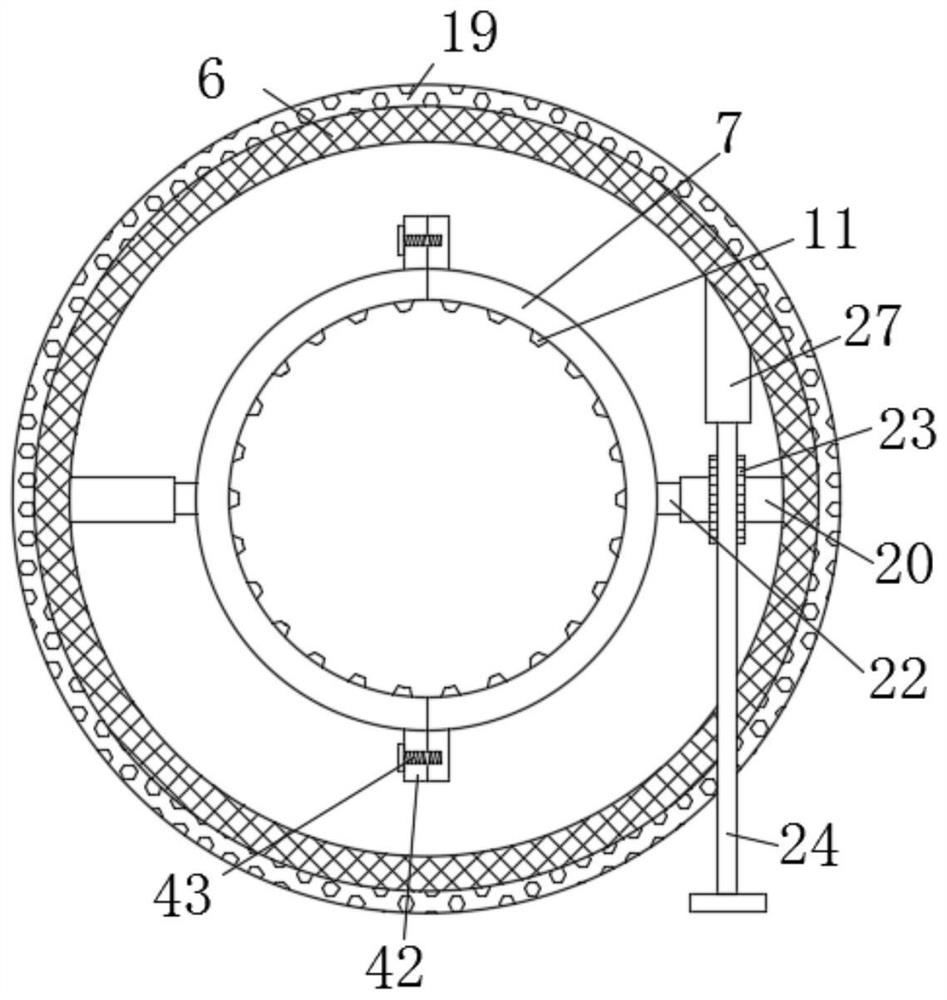

Variable-rate mist spraying system and control method

InactiveCN110178824AWide range of changesGuaranteed uniformityInsect catchers and killersEngineeringStreamflow

The invention relates to a variable-rate mist spraying system and a control method. The system includes a control module, a measuring module and a mist spraying module. The control module comprises amain control device and a controller, the measuring module comprises a speed sensor for measuring the walking speed of a walking device and a flow sensor for measuring the mist spraying flow of showernozzles, and the mist spraying module includes pesticide boxes, several water pumps and the shower nozzles, wherein the drug boxes are connected in sequence through pipelines, and the shower nozzlescorrespond to the water pumps one to one. The variation range of the mist spraying flow is enlarged, the fogdrop size is changed within a range without affecting the mist spraying effect, the uniformity and comprehensiveness of mist spraying are ensured, non-interruption continuous mist spraying is achieved, sudden change and interruption of the mist spraying flow do not exist, it is well ensuredthat the mist spraying quantity per unit area of drugs is same after a mist spraying machine runs unit length, and the utilization rates of pesticides are maximized.

Owner:秦邵恩

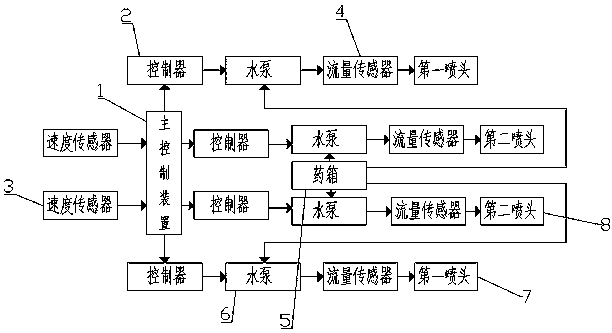

Spraying process for 3PE fully powdered coating on steel pipe

InactiveCN109590180ASimple processSave power resourcesPretreated surfacesElectrostatic heating/coolingEpoxyMetallurgy

The invention discloses a spraying process for a 3PE fully powdered coating on a steel pipe. Equipment adopted by the spraying process includes a steel pipe conveying roller, an intermediate frequencyheating device, an epoxy powder electrostatic spraying device, an adhesive powder electrostatic spraying device, a polyethylene powder electrostatic spraying device and a water cooling device. Sprayguns of the three electrostatic spraying devices are arranged adjacent to one another so as to ensure that the adhesive powder melts to form an adhesive layer before the epoxy powder solidifies, and the polyethylene powder melts to form a polyethylene layer before the adhesive layer solidifies. The epoxy powder layer, adhesive layer and polyethylene layer are all coated by powder electrostatic spraying, the pipe body does not need to be heated again, only the steel pipe needs to be heated before spraying, and the epoxy powder layer, adhesive layer and polyethylene layer are cured by the wasteheat of the steel pipe, so that the process is simple and power resources are saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

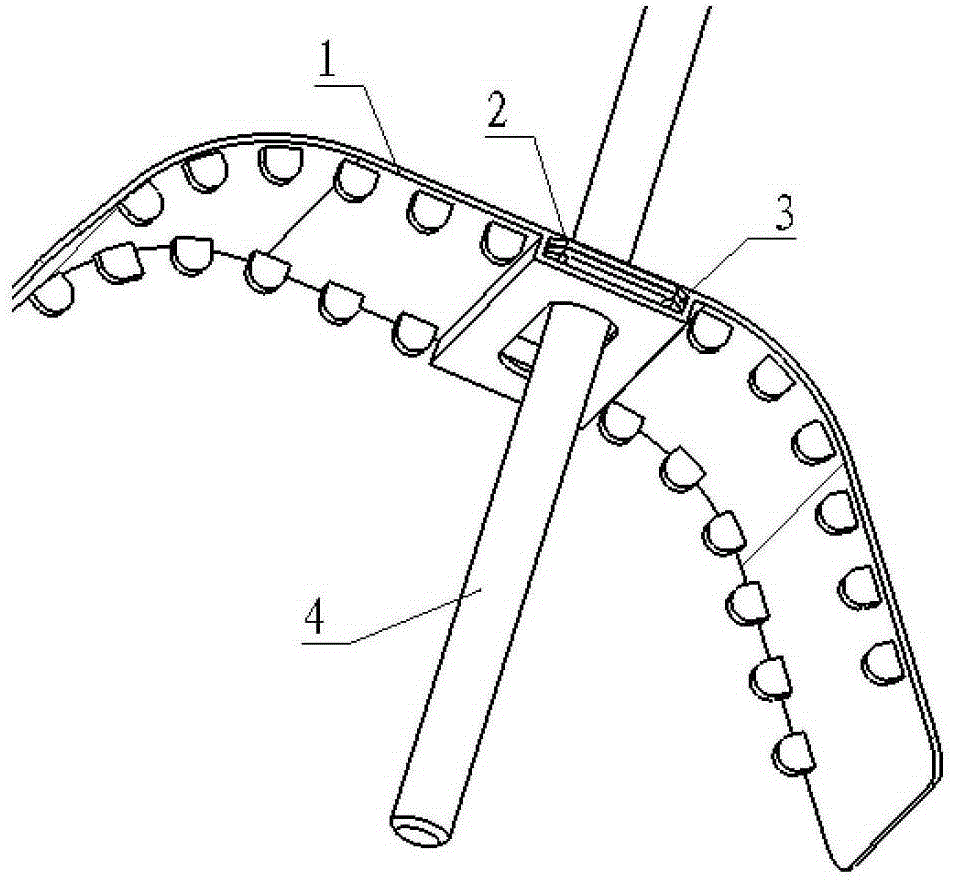

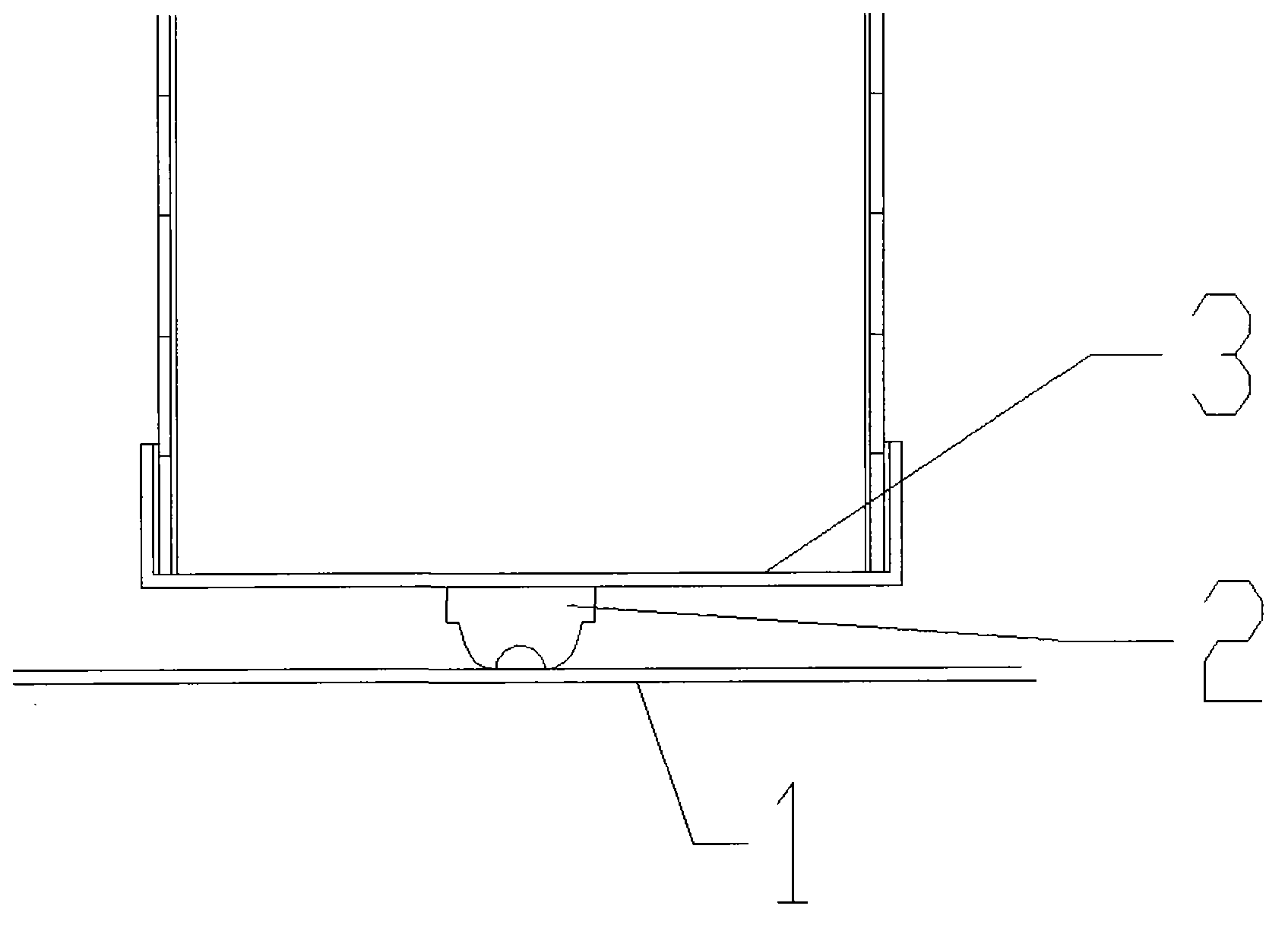

Dust proof sliding mat for shifter

ActiveCN103791090AThere will be no gapsFulfil requirementsEngine sealsEngineeringUltimate tensile strength

A dust proof sliding mat for a shifter comprises a main sliding mat, a first auxiliary sliding mat and a second auxiliary sliding mat; a first strip-shaped hole which is in the left-right direction is formed in the main sliding mat 1; the first auxiliary sliding mat is installed under the first strip-shaped hole; a second strip-shaped hole which is in the left-right direction is formed in the auxiliary sliding mat to be corresponding to the first strip-shaped hole; the second auxiliary sliding mat is installed under the first auxiliary sliding mat; a position on the second auxiliary sliding mat, which is corresponding to the second strip-shaped hole, is provided with a rounded hole which is used for assembling a shift rod; the first auxiliary sliding mat and the second sliding mat are installed in a left-right directional sliding hole which is formed in the rear side of the main sliding mat. The dust proof sliding mat for the shifter has the advantages of being attractive in appearance, satisfying requirements for the shifter in function due to the three-layer integrated structure, having a good dust proof effect, improving the structural intensity of the main sliding mat, enabling the service life of the main sliding mat to be prolonged and reducing the fault rate and reducing maintenance costs.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

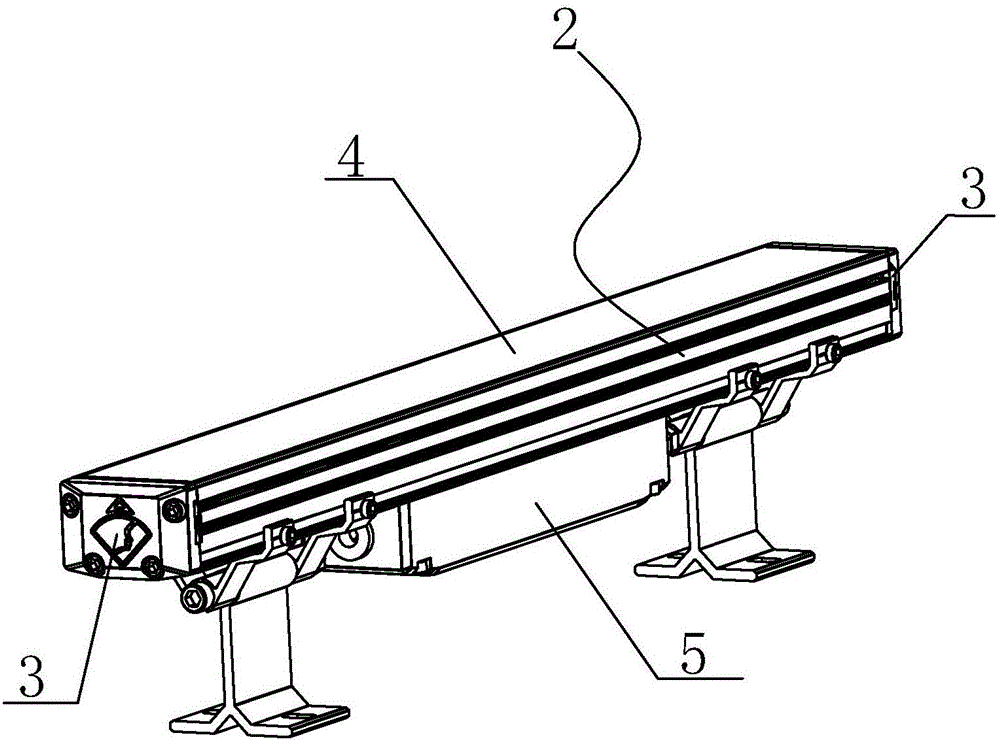

Waterproof and dustproof wall washer

InactiveCN106195790AFlat and beautiful appearanceWater seepage will not occurMechanical apparatusProtective devices for lightingEngineeringWater seepage

The invention discloses a waterproof and dustproof wall washer. The waterproof and dustproof wall washer comprises a light source plate, an integrally formed lamp outer shell, and two end covers used for covering the two ends of the lamp outer shell, wherein the lamp outer shell comprises a bottom plate, two side plates and a panel used for bonding a glass pressing plate; the bottom plate, the two side plates and the panel form a rectangular through cavity; the light source plate is placed inside the through cavity; shapes of the end covers and the two ends of the lamp outer shell are matched; and the edges of the end covers and the outer surface of the lamp outer shell are flush. According to the waterproof and dustproof wall washer, the appearance of the wall washer is smooth and beautiful, gaps capable of accumulating dust and seeping water are avoided, and the wall washer does not have the phenomenon of water seepage.

Owner:广东人和照明实业有限公司

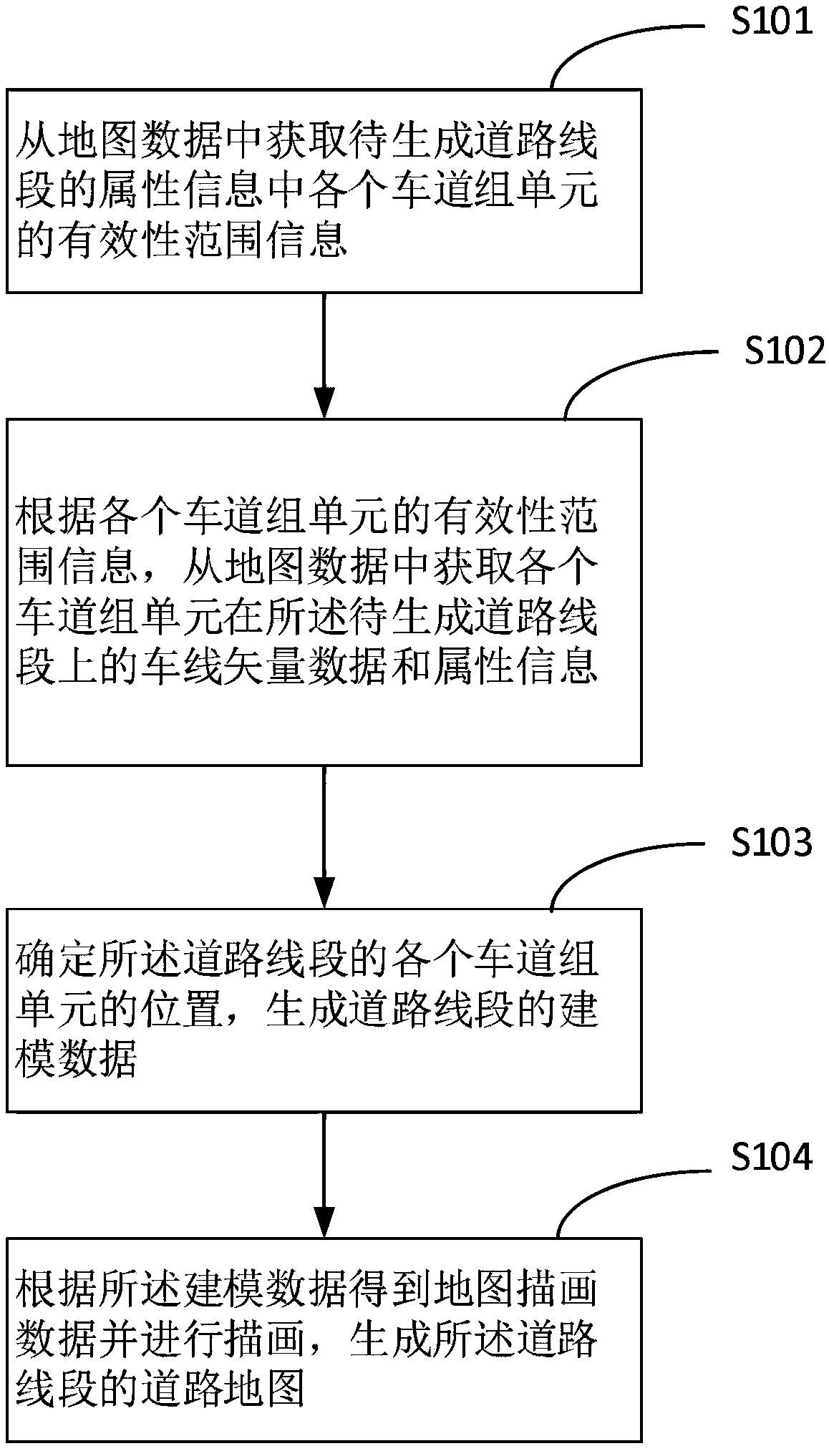

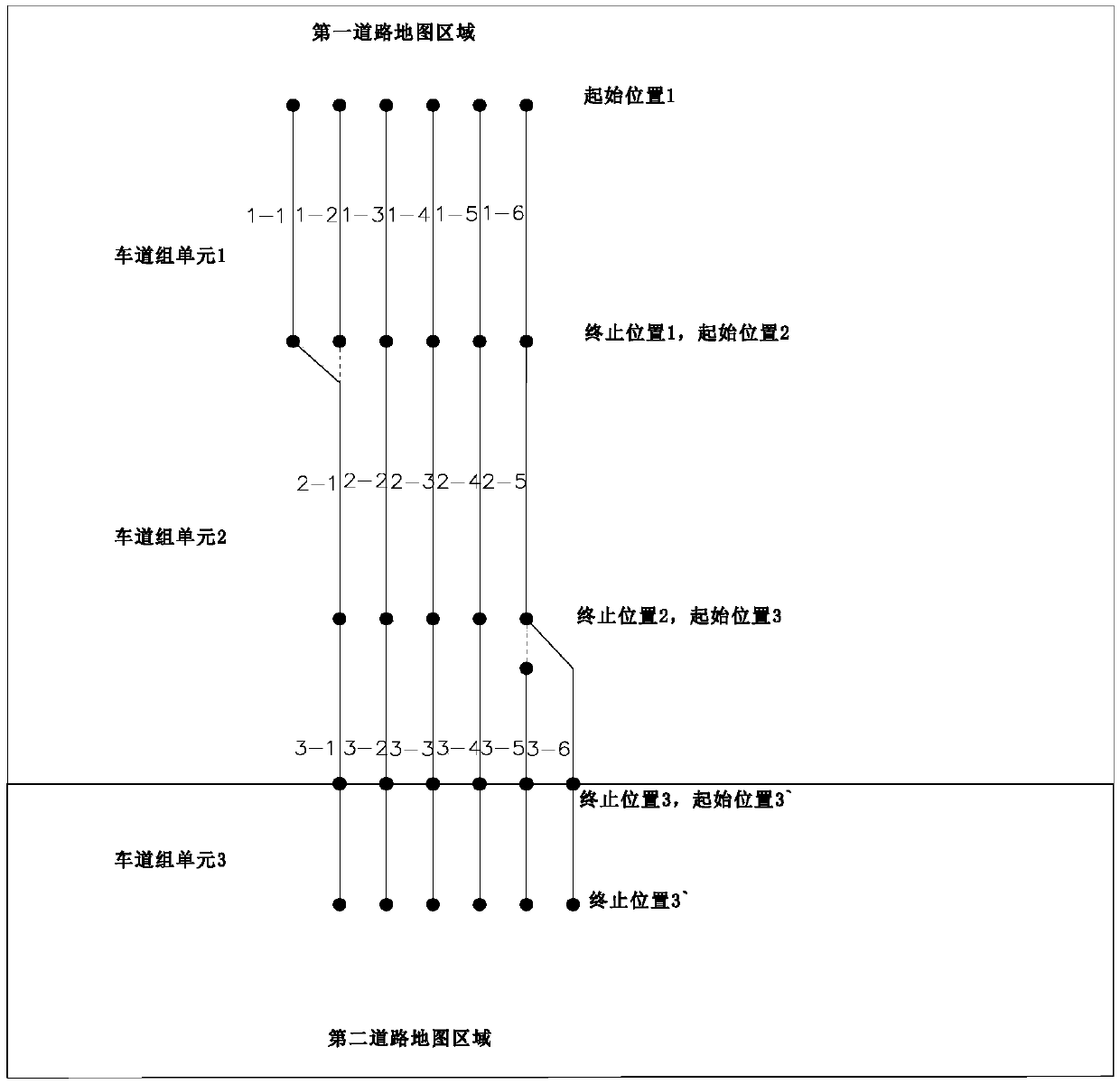

Map generation method and device for road segment and related system

ActiveCN111238503AImprove finenessNo missingInstruments for road network navigationRoad mapComputer vision

The invention discloses a map generation method and device for a road segment and a related system. The method comprises the steps of obtaining validity range information of each lane group unit in attribute information of a to-be-generated road segment from map data, according to the validity range information of each lane group unit, obtaining vehicle line vector data and attribute information of each lane group unit on the to-be-generated road segment from map data, determining the position of each lane group unit of the to-be-generated road segment, and generating modeling data of the roadsegment, and obtaining map drawing data according to the modeling data and drawing to generate a road map of the road segment. The generated road map of the road segment can display a complete map ofthe road segment in the road map area to which the road segment belongs, the phenomenon of lane line missing or lane butt joint gaps is avoided, lane-level map display of the generated road map is achieved, the map display fineness is improved, and lane information more conforming to a real road is displayed.

Owner:SHENYANG MXNAVI CO LTD

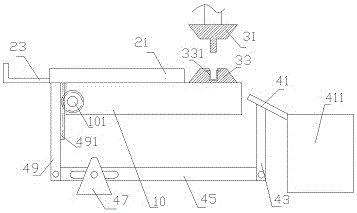

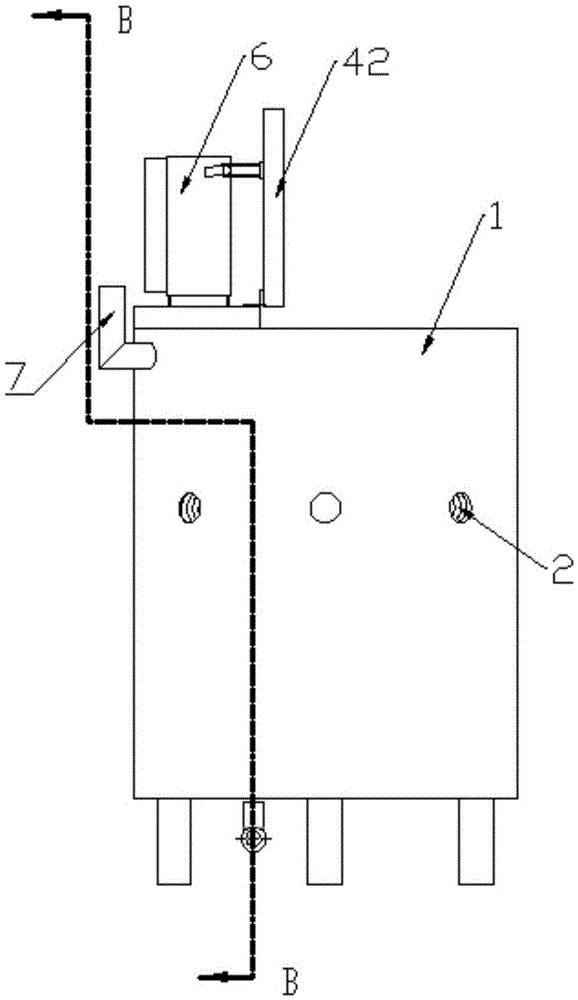

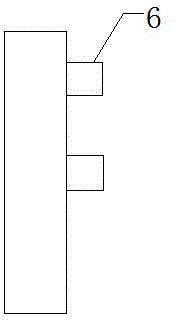

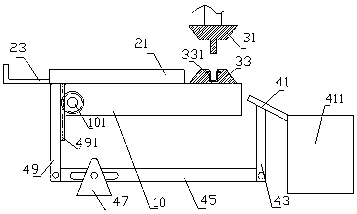

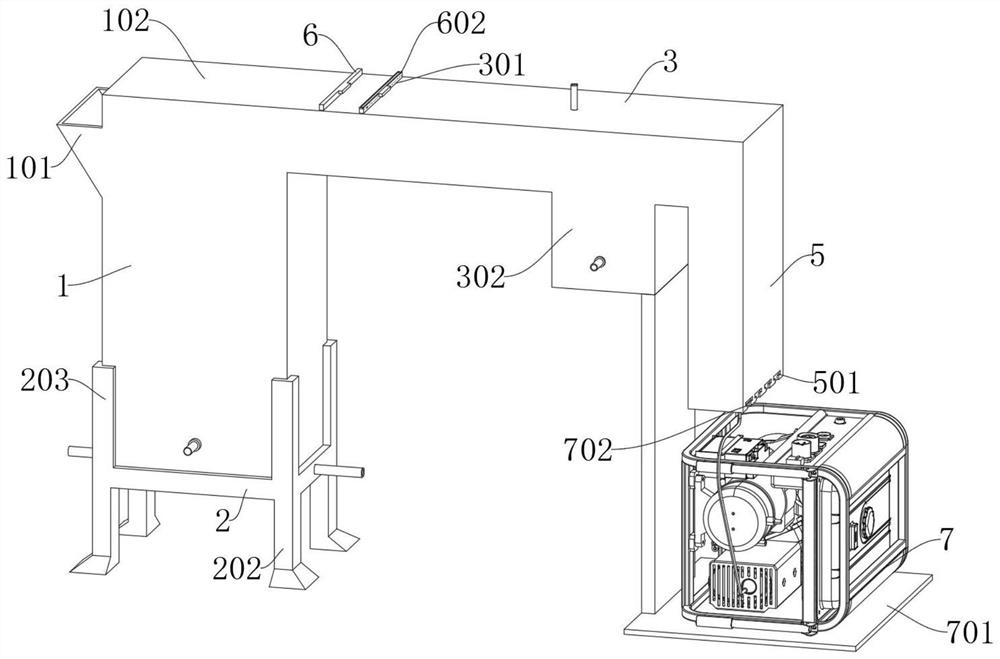

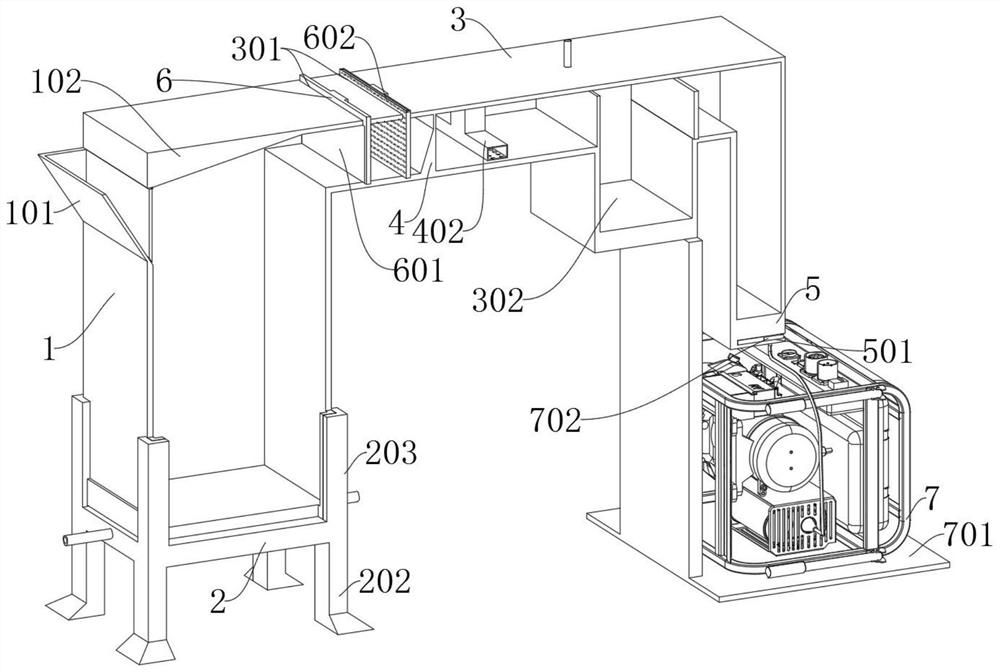

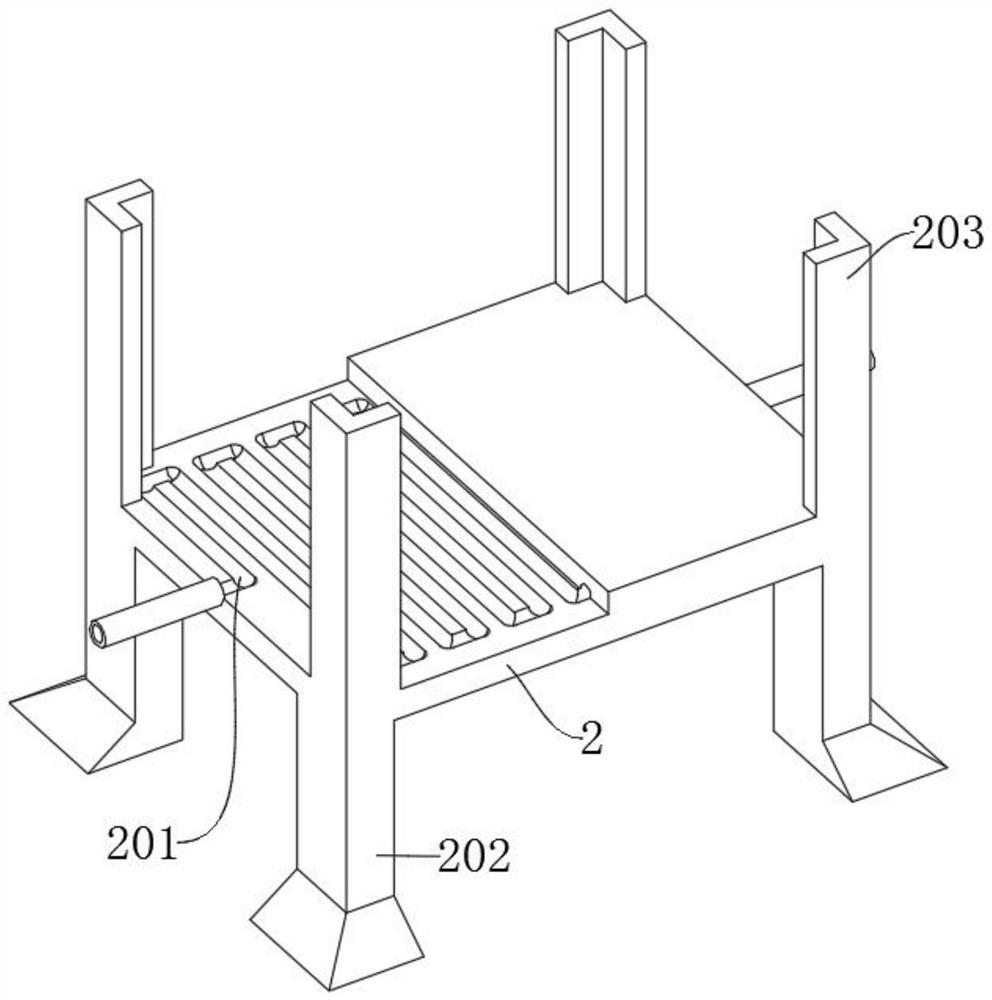

Automatic steel tube punching machine

ActiveCN106583530AThere will be no gapsEasy to assembleMetal-working feeding devicesPositioning devicesSteel tubeHigh probability

The invention relates to the field of die processing, in particular to an automatic steel tube punching machine. The automatic steel tube punching machine comprises a worktable, as well as a guiding plate and a punching mechanism which are both positioned above the worktable, wherein the punching mechanism comprises an upper punch die doing reciprocating motion and a lower punch die fixed on the worktable; a lifting mechanism is further arranged below the worktable and comprises an inclined support plate, a first connecting rod, a link, a base and a second connecting rod; the support plate is positioned below the discharge opening of the lower punch die; the lower end of the support plate is connected to the upper end of the first connecting rod; the lower end of the first connecting rod is hinged to one end of the link; the other end of the link is hinged to the lower end of the second connecting rod; the middle of the link is hinged to the base; and the upper end of the second connecting rod is propped against the lower end, far away from the punching mechanism, of the guiding plate. The invention aims to provide the automatic steel tube punching machine to solve the problem that in the prior art, as a steel tube is obliquely fed into the punch dies, notches at the two ends of the punched steel tube have high probability of cracking.

Owner:CHONGQING YOUBO MACHINERY MFG

Baking-free brick made of paper mill sludge

The invention discloses a baking-free brick made of paper mill sludge. The baking-free brick comprises, by weight, 20-35 parts of paper mill sludge, 20-30 parts of cement, 5-18 parts of slaked lime, 10-16 parts of diatomaceous earth, 18-26 parts of coal gangue, 20-28 parts of modified bamboo powder, 20-35 parts of foundation dug soil, 2-5 parts of Arabic gum, 4-8 parts of acrylic resin, 0.5-2.5 parts of sodium silicate, 1-2 parts of curing agents, 0.5-1 part of water reducing agents and 25-35 parts of water. The baking-free brick has the advantages that the baking-free brick has uniform density and is good in antibacterial property, and various positions of the baking-free brick are uniform in pressure-resistant degree; the baking-free brick is environmentally friendly and is low in cost, waste can be turned into wealth, and accordingly natural resources can be saved.

Owner:无为县严桥双龙建材厂(普通合伙)

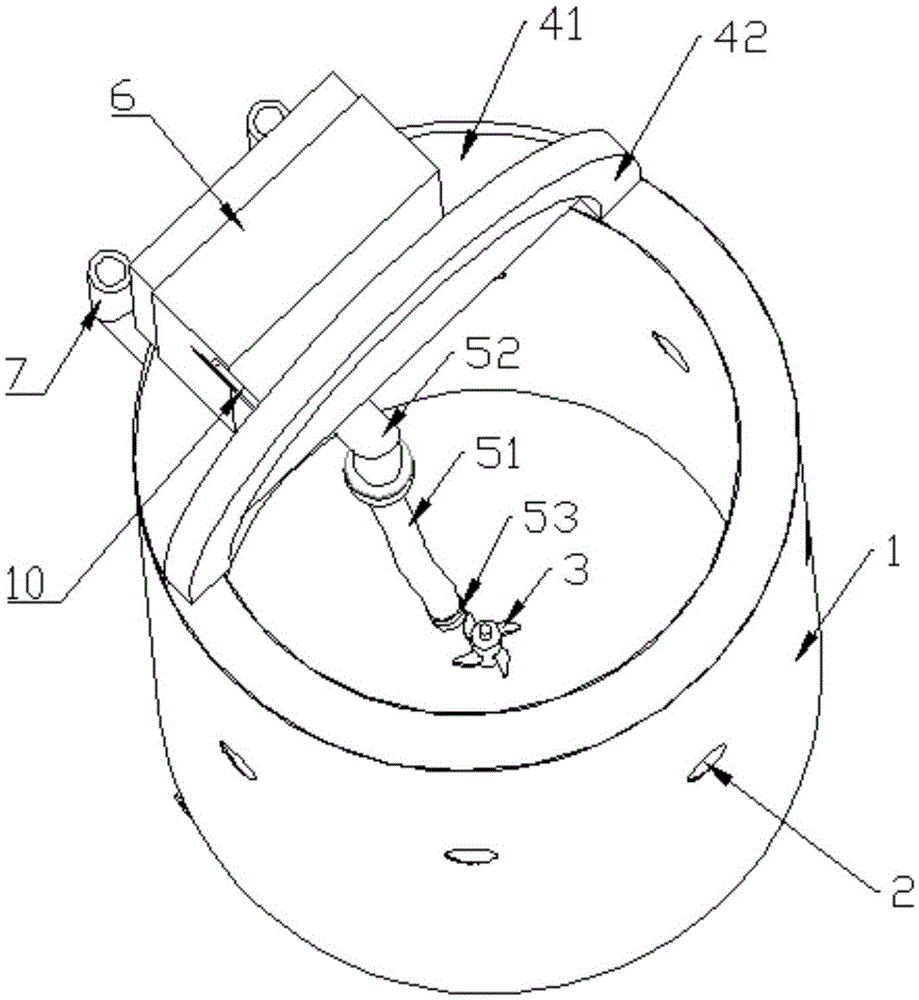

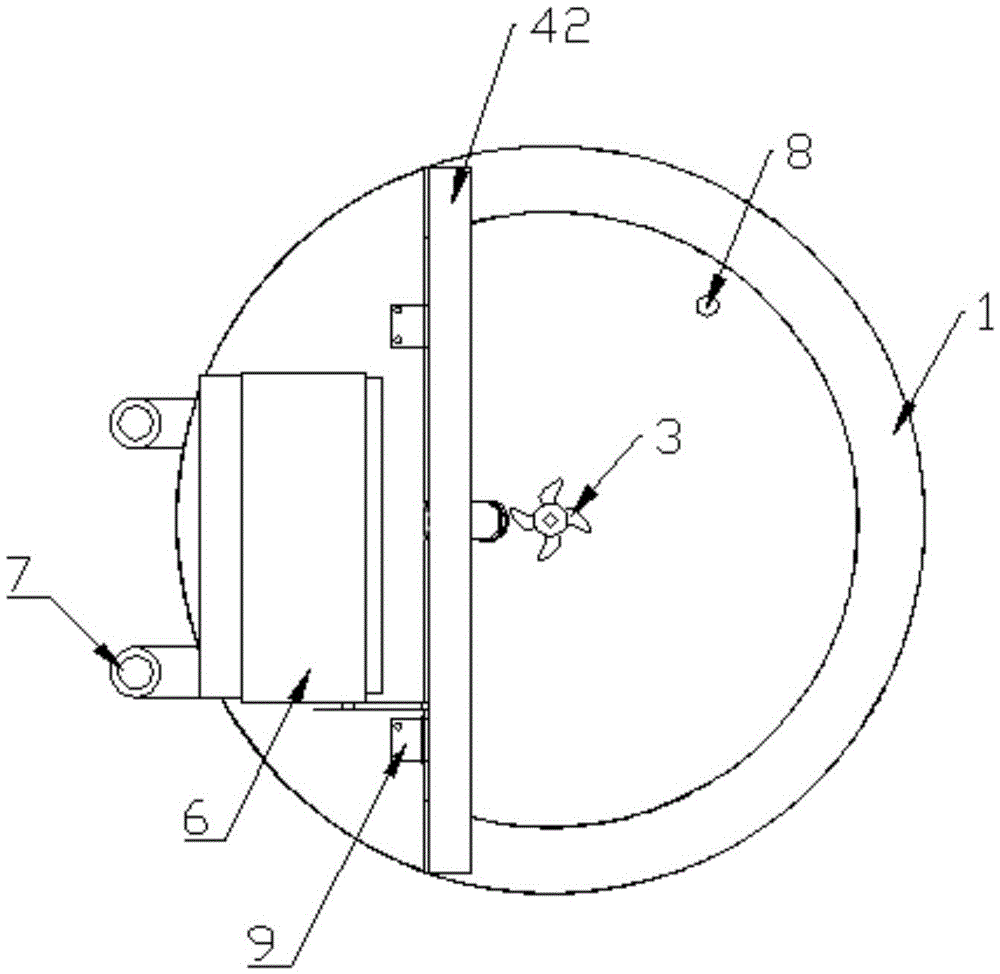

Mammal feeder

InactiveCN105607677AShorten the timeGuaranteed temperatureTemperatue controlAnimal feeding devicesHeifer calfMammal

The invention provides a mammal feeder, comprising a milk vessel, a stirrer, a heating assembly, a control assembly and a feeding assembly, wherein a nipple fixing hole is formed in the wall of the milk vessel, a nipple is connected to the outer wall of the milk vessel via the nipple fixing hole, and the stirrer is arranged in the milk vessel; the feeding assembly comprises a straw and a check valve, the check valve is arranged at one end of the straw, the milk vessel comprises a solution accommodating cavity, the check valve is arranged in the solution accommodating cavity, and the nipple is communicated with the solution accommodating cavity via the straw; and the heating assembly is used for heating matters in the solution accommodating cavity. The mammal feeder can reduce manual intervention, feed small mammals such as cattle and sheep, reduce manual timed feeding at the same time and feed animals with required milk.

Owner:刘海波

Solid waste gasification power generation method

ActiveCN112029534AImprove recycling effectExtension of timeInternal combustion piston enginesGasification processes detailsThermodynamicsProcess engineering

The invention provides a solid waste gasification power generation method, and relates to the technical field of waste power generation, the solid waste gasification power generation method is completed by a solid waste gasification power generation device, and then solid waste gasification power generation is realized. The problems that when an existing garbage gasification power generation method is used and garbage is combusted, the heat recovery effect is poor, heat cannot be recovered in a multi-layer mode, and heat cannot be recovered from multiple angles are solved.

Owner:赵明星

A dust-proof sliding pad for a gear shifter

ActiveCN103791090BThere will be no gapsFulfil requirementsEngine sealsUltimate tensile strengthFault rate

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

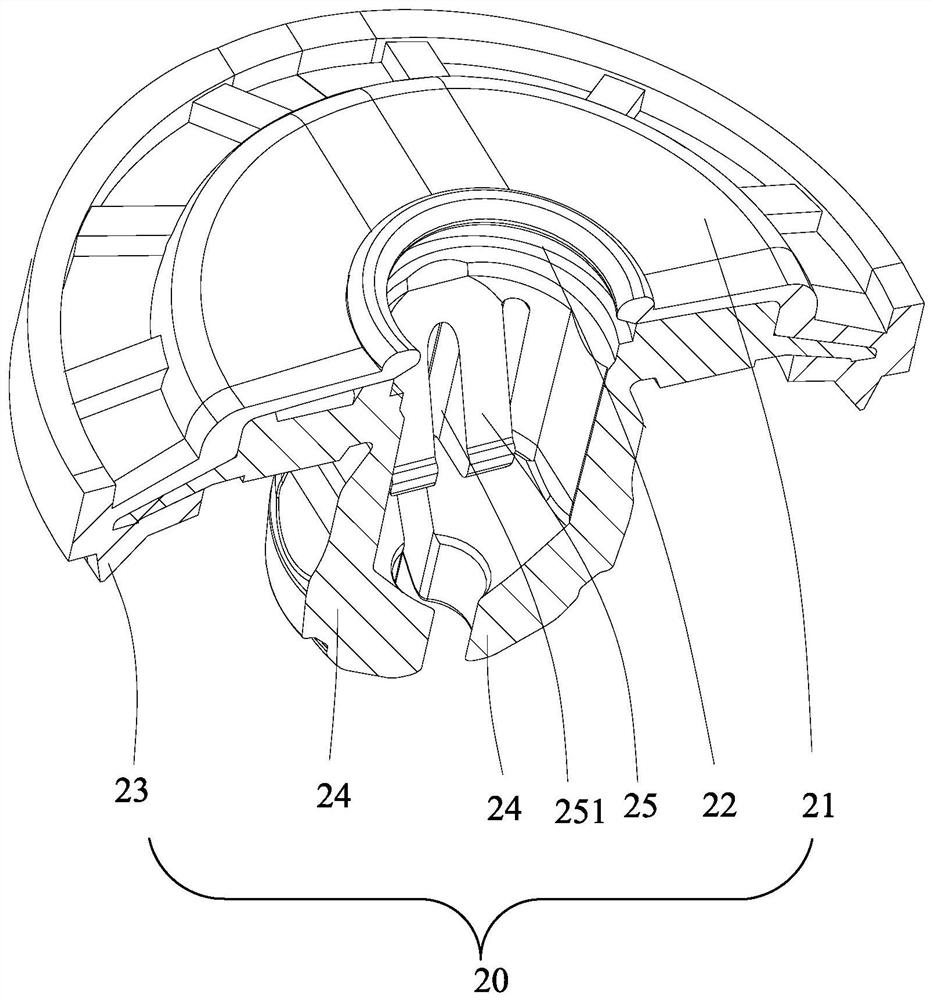

Fixing device

The invention relates to a fixing device. The fixing device comprises a connecting piece, a joint piece and an end cap, wherein the connecting piece comprises a body, a flange, an embedded portion and a groove portion, the groove portion comprises a groove and a conical section, the joint piece comprises a cover body, a sealing rib, opening and closing elements and a clamping and locking element, and the cover body is of an arch-shaped structure and is symmetrically arranged by taking a symmetric plane as a symmetry plane. The two opening and closing elements are symmetrically arranged by taking a symmetric plane as a symmetric plane, the symmetric plane of the two opening and closing elements and the symmetric plane of the cover body coincide with each other, the cover body is arched towards the flange by taking a symmetric plane coincide with the symmetric plane of the two opening and closing elements as a standard, and the opening direction of the cover body faces the opening and closing elements, so that the opening and closing elements drive the cover body to be bent in the opening process of the opening and closing elements, the cover body which is originally in an arch shape becomes flat after the opening and closing elements are opened, the cover body and a carrier are attached more tightly, no gap exists, and the sealing performance and the structural strength are improved.

Owner:JIAXING HANGONG AUTOMOBILE FASTENER CO LTD

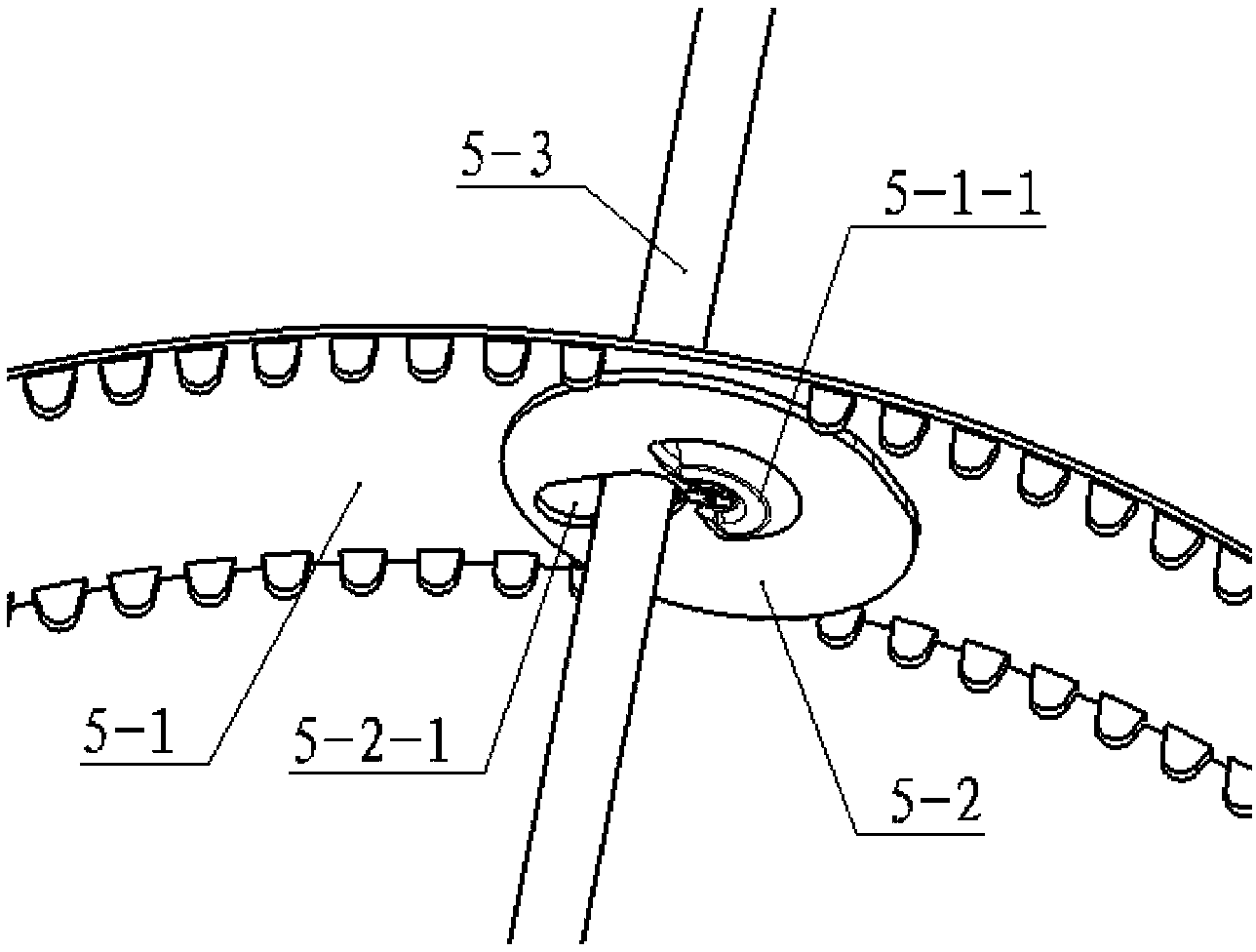

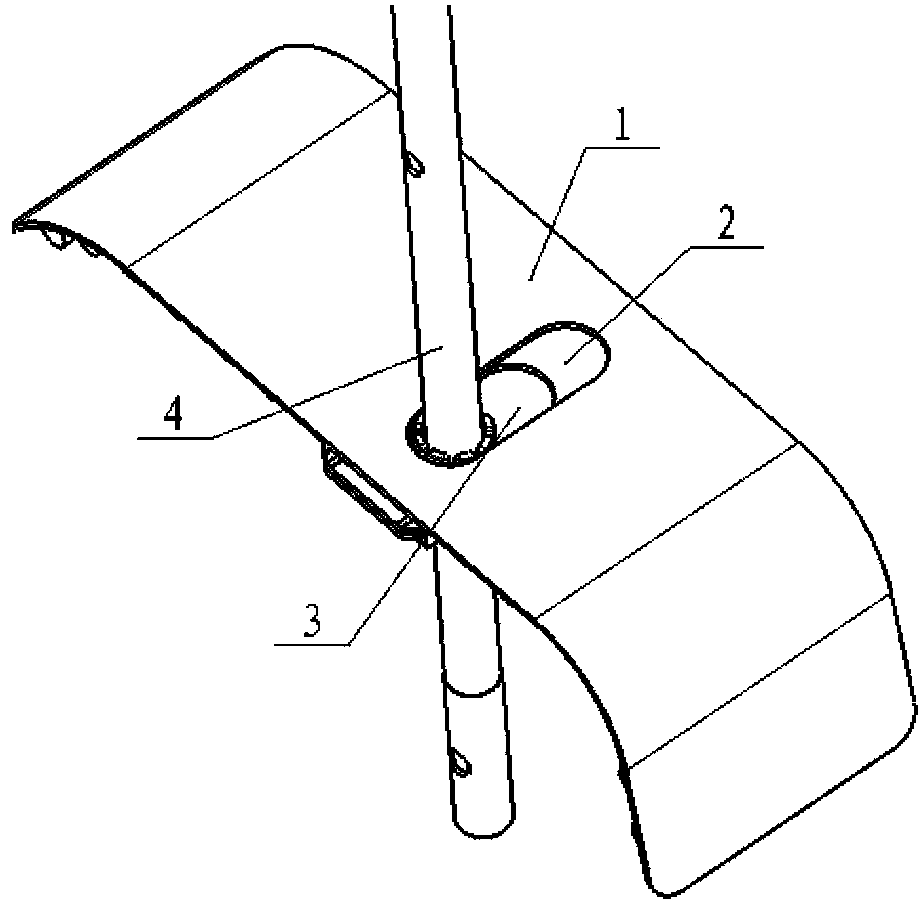

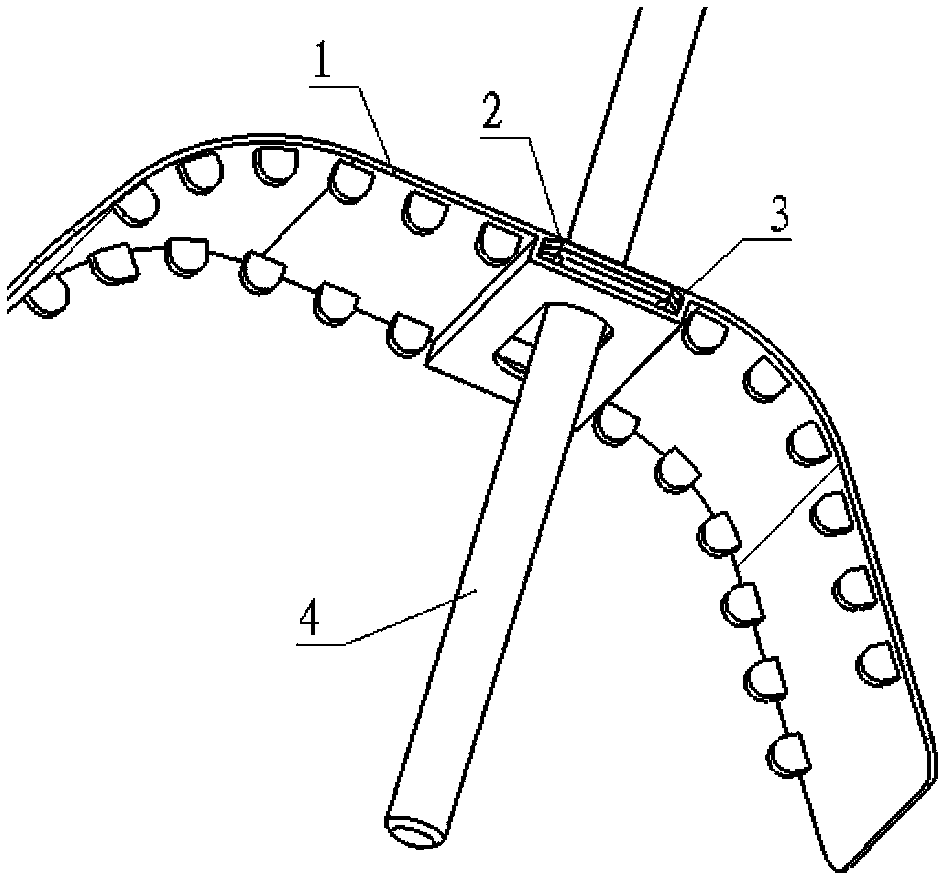

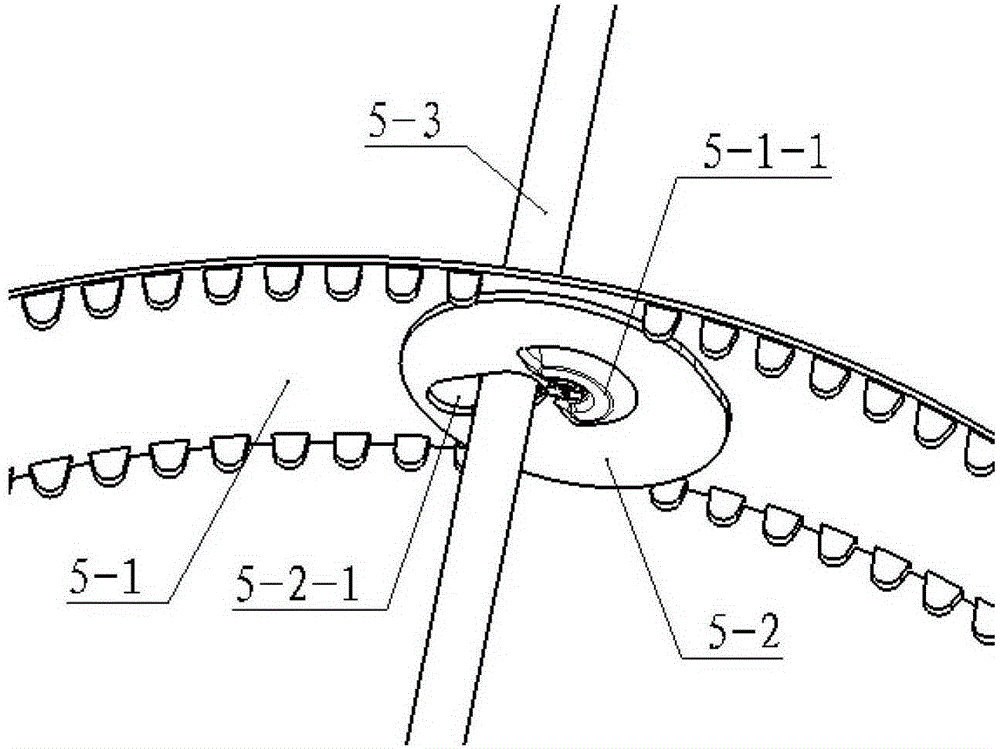

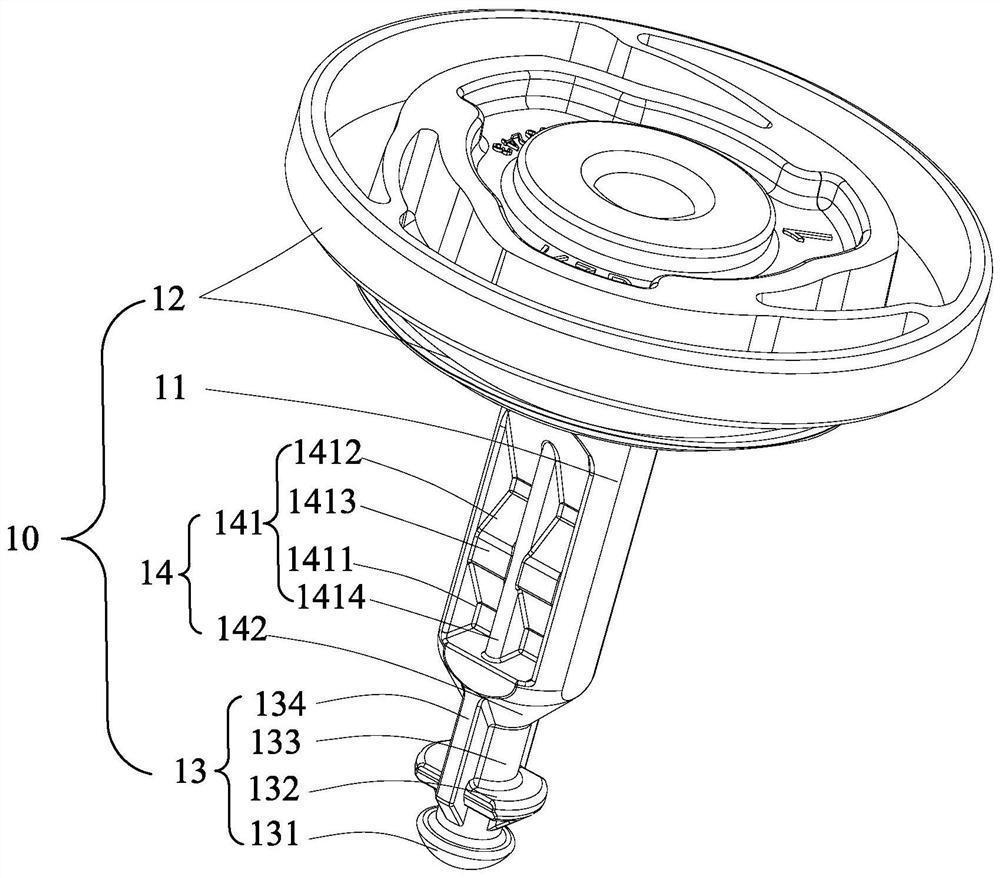

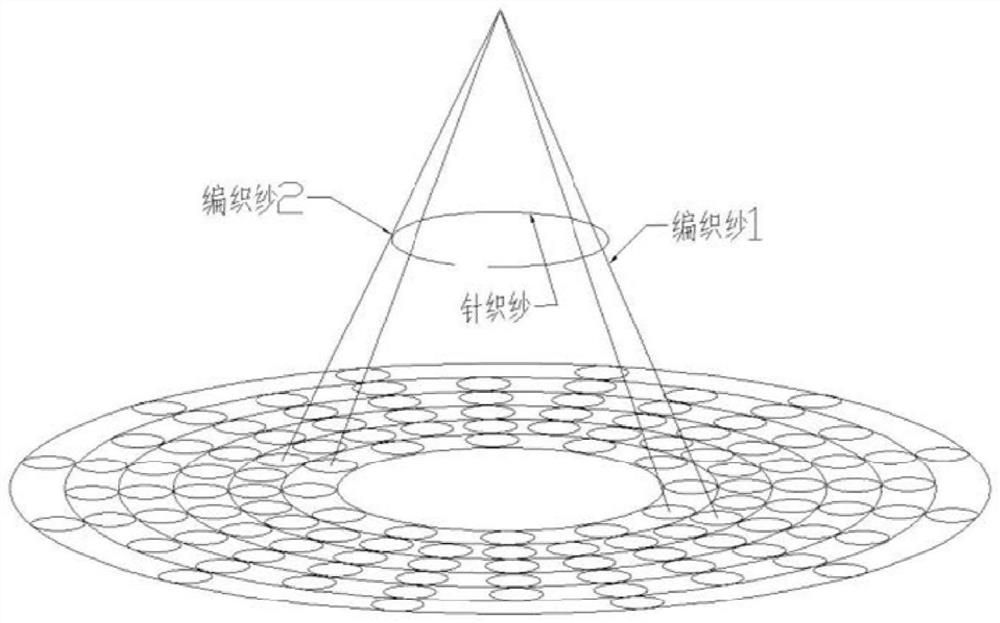

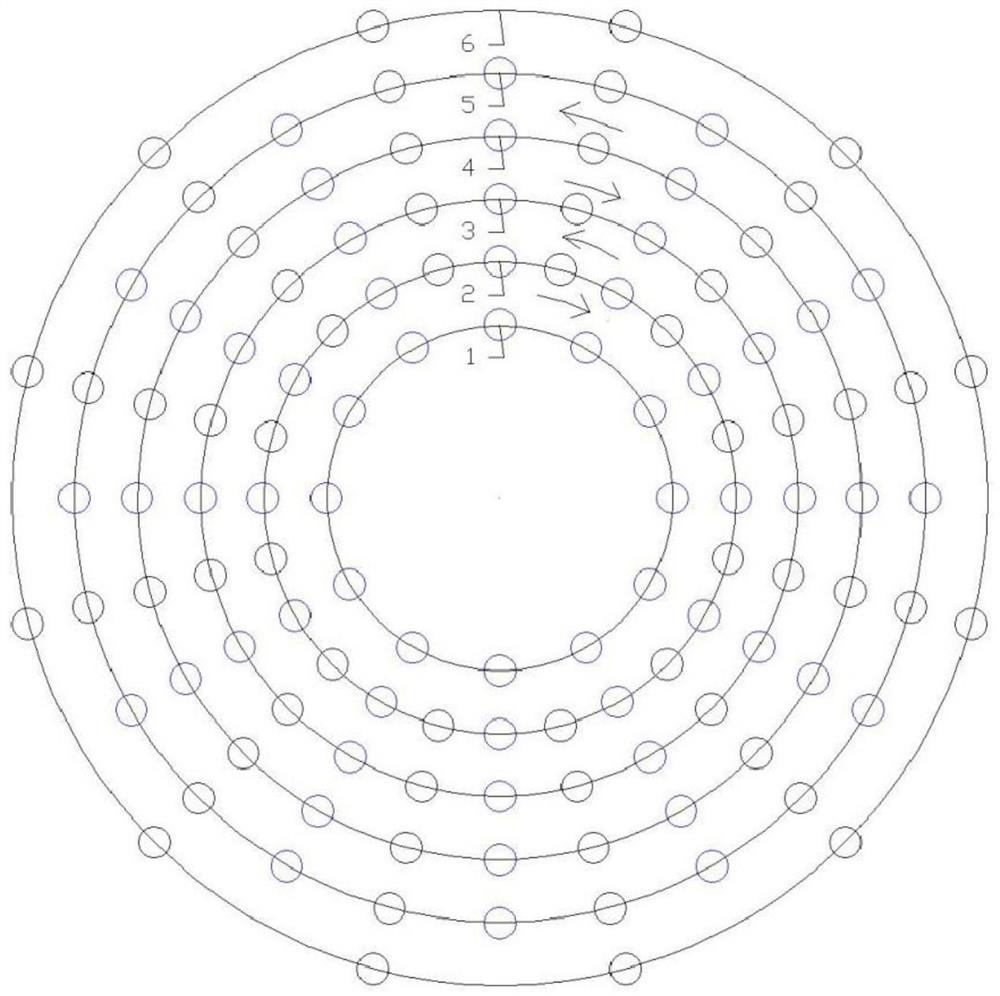

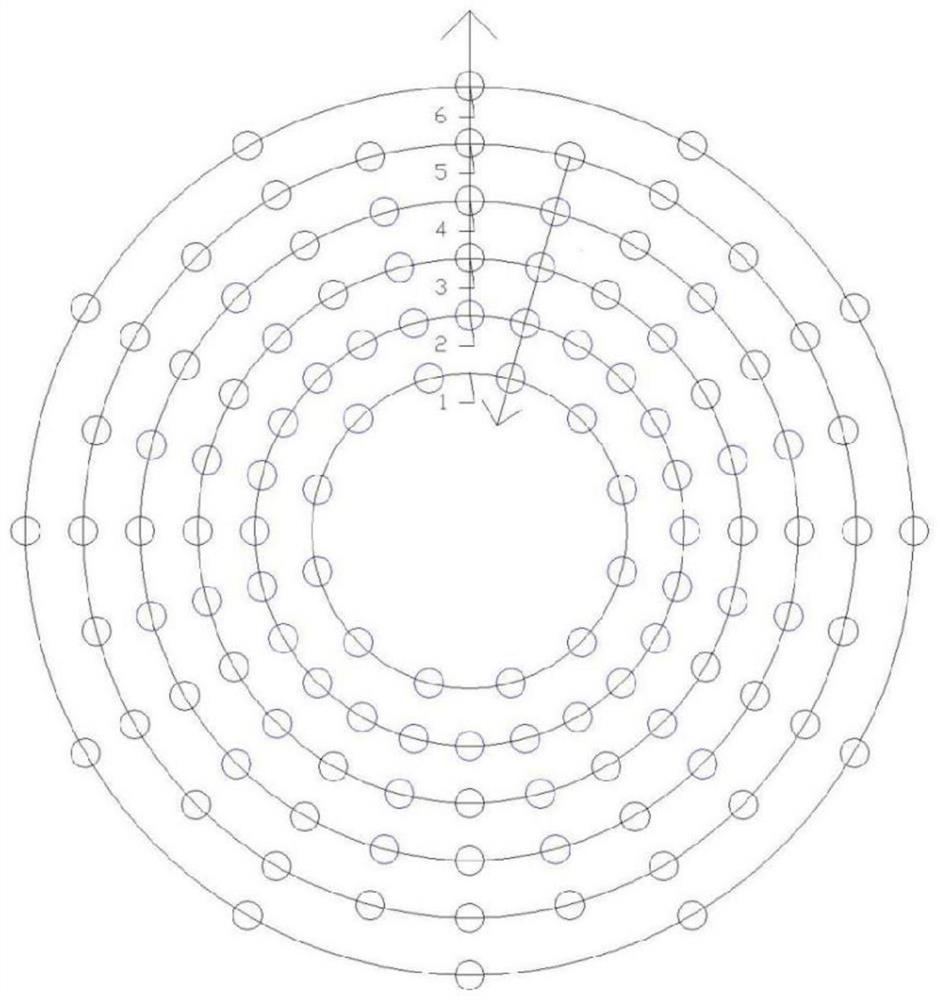

Weaving method of high-temperature-resistant composite material container pre-woven body

The invention discloses a weaving method of a high-temperature-resistant composite material container pre-woven body. The weaving method comprises the following steps of weaving by using a knitting and three-dimensional weaving mode, adding an independent yarn while performing radial and circumferential four-step three-dimensional weaving, and knitting the yarn for a circle in the circumferential direction by using a knitting mode, so that three-dimensional weaving and knitting are carried out alternately. After a certain length is woven, the arrangement position of a yarn carrier is expanded outwards according to a certain rule, three-dimensional weaving and knitting are carried out after expansion, finally, the diameter of the woven fabric is gradually expanded to form a container, and knitting yarn is used for edge sealing. The method ensures that the whole container pre-woven body does not have any defects of faults, different gap sizes and the like, the circumferential knitting yarns ensure that the container pre-woven body can bear relatively large internal pressure, and the structural stability is ensured; and the integrally woven and formed container is uniform in weaving density, free of defects such as faults and good in mechanical property, and the weaving method is suitable for weaving any conical or cylindrical containers and has relatively high universality.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Ship spraying robot capable of perceiving and recognizing specific marks based on computer vision

InactiveCN113560087AImprove intelligenceEasy to useSpraying apparatusManipulatorComputer-on-moduleSimulation

The invention discloses a ship spraying robot capable of perceiving and recognizing specific marks based on computer vision. The ship spraying robot comprises a moving seat and a U-shaped pipe, the bottom of the moving seat is provided with a first motor, the top of the moving seat is provided with a controller, the top of the moving seat is provided with a mounting box, the mounting box is located on one side of the controller, a storage barrel is mounted at the top of the moving seat and located on one side of the controller, and a pressure pump is mounted at the top of the moving seat. According to the ship spraying robot, a GPS positioning module, a computer vision module and a perceiving and recognizing module are mounted at the top of a first mounting plate, the computer vision module can simulate automatic tasks which can be completed by a human vision system, the perceiving and recognizing module is connected with a recognizing camera, through the perceiving and recognizing module and the perceiving and recognizing camera, the device can carry out recognition on the positions of the specific marks, and therefore a spraying device can spray the specific mark, and the device is more intelligent.

Owner:南通大学技术转移中心有限公司

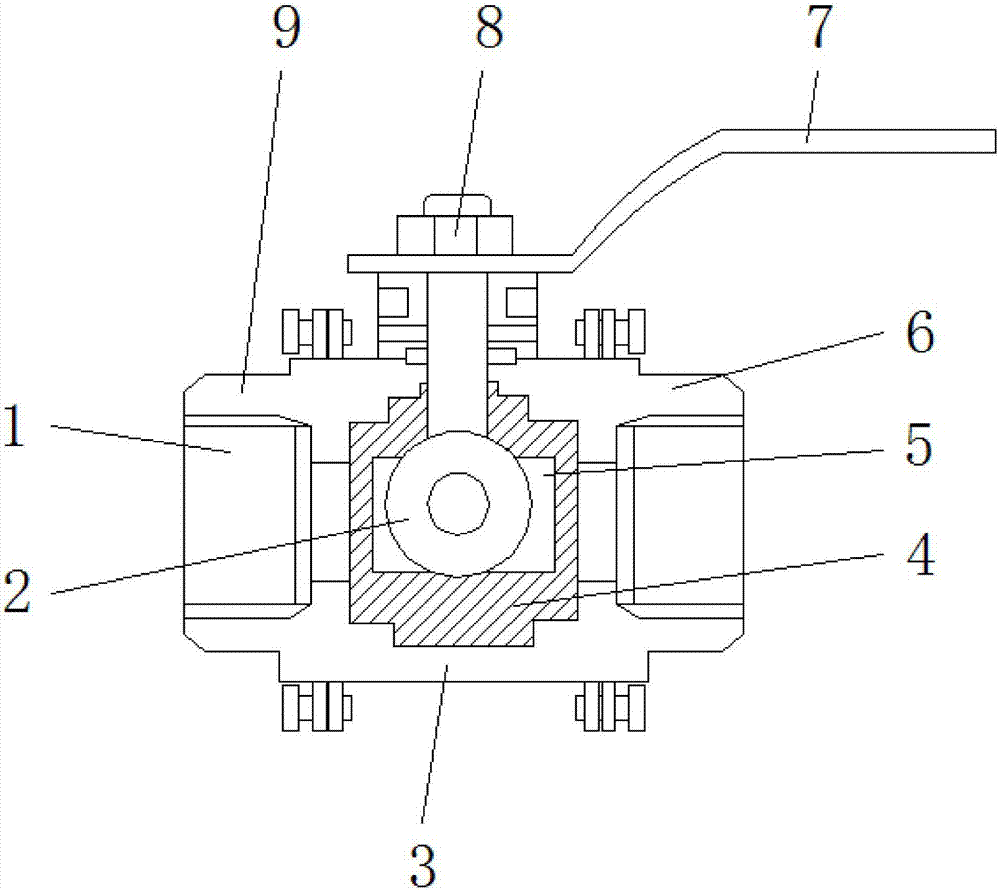

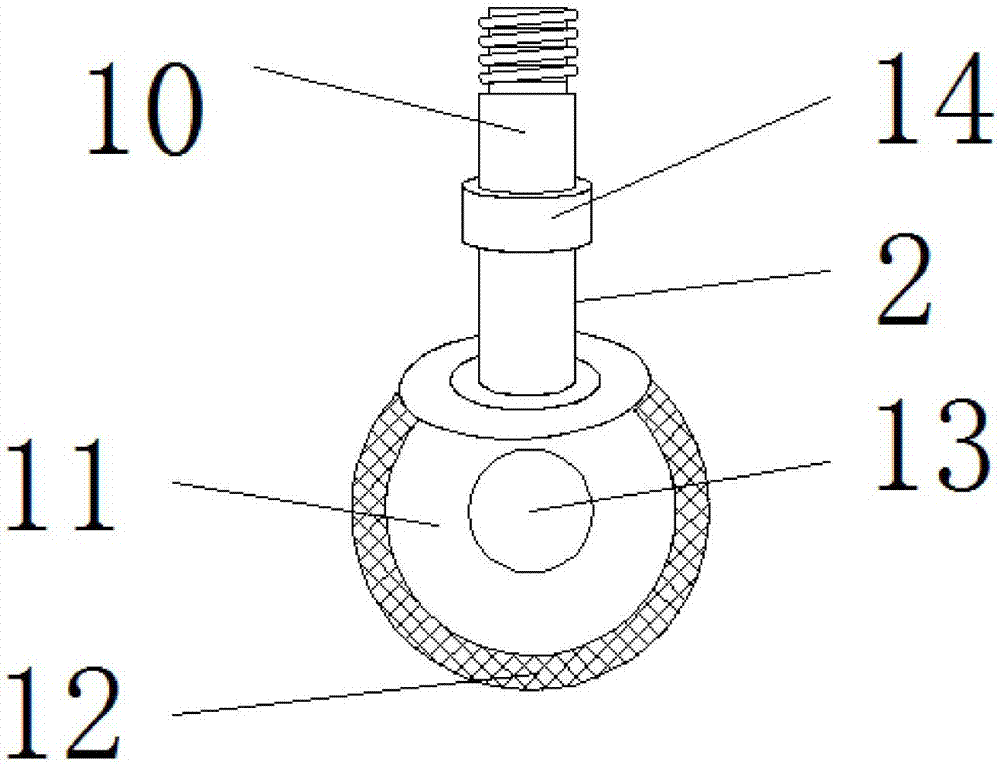

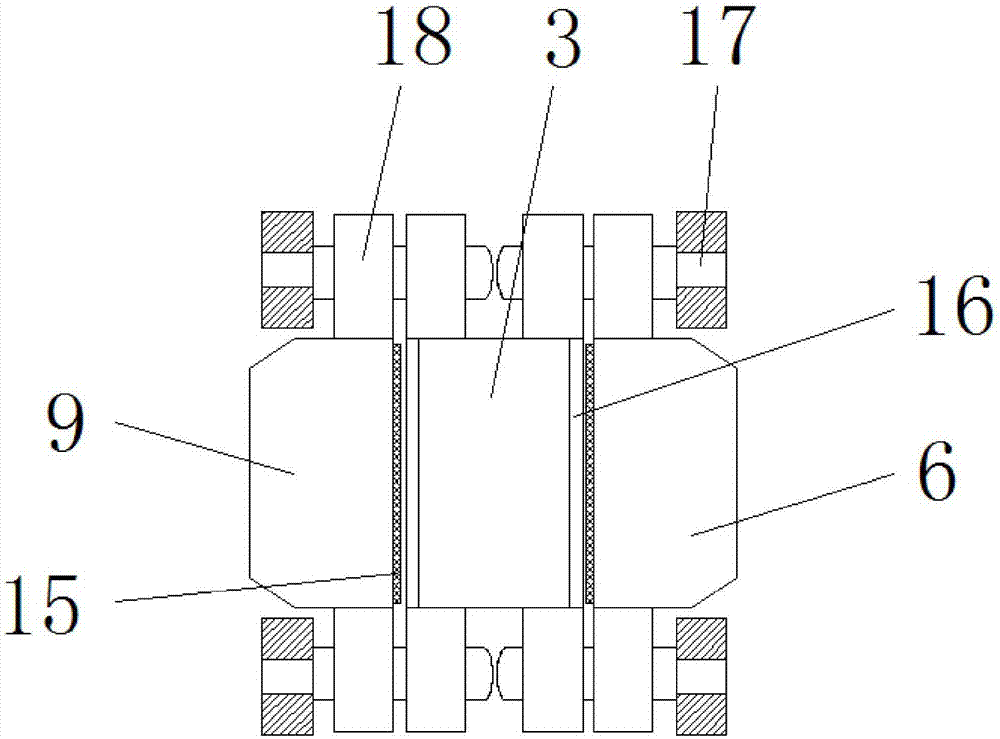

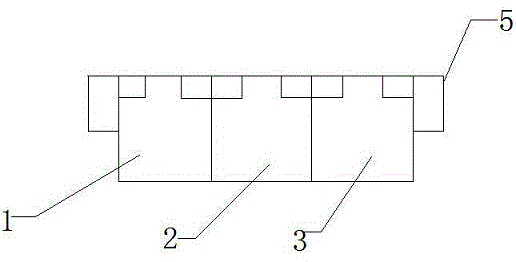

Five-clack type three-way ball valve

InactiveCN107339460APrevent side leakageEasy to disassemblePlug valvesOperating means/releasing devices for valvesVALVE PORTBall valve

Disclosed is a five-clack type three-way ball valve. The five-clack type three-way ball valve comprises a central valve body. A second valve body is fixedly connected to one end of the central valve body, a first valve body is fixedly connected to the other end of the central valve body, and connectors are arranged inside the second valve body and the first valve body. A leakage-proof gasket is fixedly arranged inside the central valve body, and a through pipe is fixedly installed inside the leakage-proof gasket. A valve element is installed inside the through pipe in a rotary mode, a clamp nut is fixedly installed at the upper end of the valve element, and a valve rod is fixedly connected with the upper end of the valve element. A bearing is fixedly installed at the upper end of the valve rod, a ball is fixedly connected to the lower end of the valve rod, a rubber gasket fixedly sleeves the outer side of the ball in a connected mode, and a ball valve hole is fixedly formed in one side of the ball. Fixing threaded blocks are symmetrically and fixedly connected to the two ends of the central valve body, the two ends of a sealing groove and the two ends of the second valve body. The five-clack type three-way ball valve can effectively conduct leakage prevention in the using process, and is convenient to maintain.

Owner:芜湖凡达机械科技有限公司

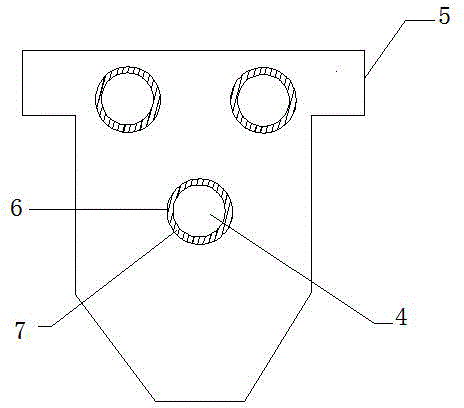

Socket shaped like Chinese character 'pin'

InactiveCN104538795AThere will be no gapsPrevent flying outCoupling device detailsChinese charactersInverted t

The invention discloses a socket shaped like the Chinese character 'pin'. The socket shaped like the Chinese character 'pin' comprises a left terminal jack, a middle terminal jack, a right terminal jack and three power line ports which are formed in the lower end face of the socket, wherein the left terminal jack, the middle terminal jack and the right terminal jack are connected in parallel, the left terminal jack and the right terminal jack are located on the two sides of the middle terminal jack and are as long as the middle terminal jack, the initial point of the left terminal jack and the initial point of the right terminal jack are located in the middle of the middle terminal jack, the socket is formed through injection molding, and the interior of the left terminal jack, the interior of the middle terminal jack and the interior of the right terminal jack are each of an inverted-T-shaped structure. The socket shaped like the Chinese character 'pin' is simple in structure and reasonable in design, terminals can be prevented from being disengaged from the socket, friction between a power line and the socket is avoided, the safety performance of an air-condition compressor is improved, cost is low, and practical value is high.

Owner:WUHU WANHUA PLASTIC PROD

Steel pipe automatic punching machine

ActiveCN106583530BThere will be no gapsEasy to assembleMetal-working feeding devicesPositioning devicesPunchingReciprocating motion

The invention relates to the field of die processing, in particular to an automatic steel tube punching machine. The automatic steel tube punching machine comprises a worktable, as well as a guiding plate and a punching mechanism which are both positioned above the worktable, wherein the punching mechanism comprises an upper punch die doing reciprocating motion and a lower punch die fixed on the worktable; a lifting mechanism is further arranged below the worktable and comprises an inclined support plate, a first connecting rod, a link, a base and a second connecting rod; the support plate is positioned below the discharge opening of the lower punch die; the lower end of the support plate is connected to the upper end of the first connecting rod; the lower end of the first connecting rod is hinged to one end of the link; the other end of the link is hinged to the lower end of the second connecting rod; the middle of the link is hinged to the base; and the upper end of the second connecting rod is propped against the lower end, far away from the punching mechanism, of the guiding plate. The invention aims to provide the automatic steel tube punching machine to solve the problem that in the prior art, as a steel tube is obliquely fed into the punch dies, notches at the two ends of the punched steel tube have high probability of cracking.

Owner:CHONGQING YOUBO MACHINERY MFG

Industrial production method of stranded earphone cord

The invention relates to an industrial production method of a stranded earphone cord, which is characterized by comprising the following production steps: (1) doubling and extruding; a two-earphone-cord combining wire pasted by a coating layer is produced by an extrusion machine; (2) twisting: the produced combining wire is twisted by a wire twisting machine; and (3) heating setting; the twisted wire is heated and set through a high-temperature area. The earphone cords can not be dispersed from two ends after being twisted, dispersion phenomenon can not happen after segmentation, and the phenomenon of generation of a gap between the double cords at the bending part of the earphone wire can not happen, therefore, remarkable effect is achieved owning to the new process of doubling and extruding; besides, the stress of the stranded wire is eliminated after high-temperature setting, and self-winding phenomenon can not happen, therefore, the production efficiency and finished product ratioare greatly improved and the product performance is greatly improved.

Owner:HUBEI YINGTONG ELECTRONICS

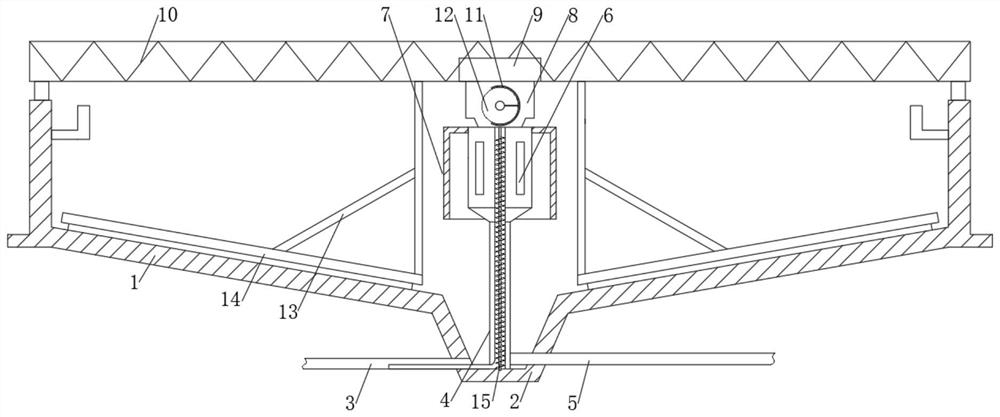

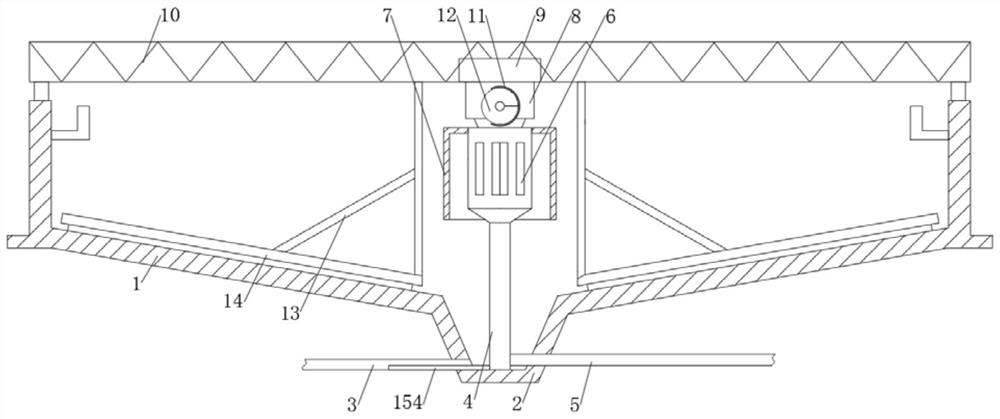

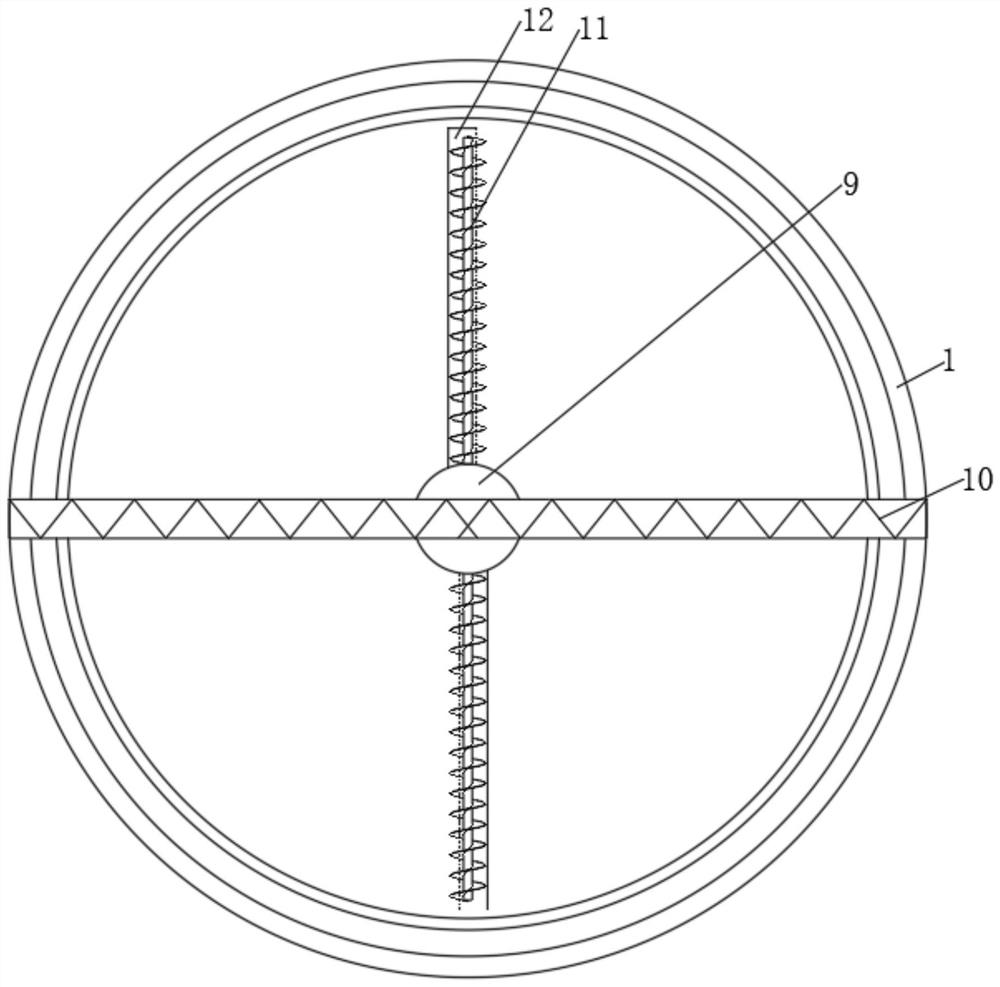

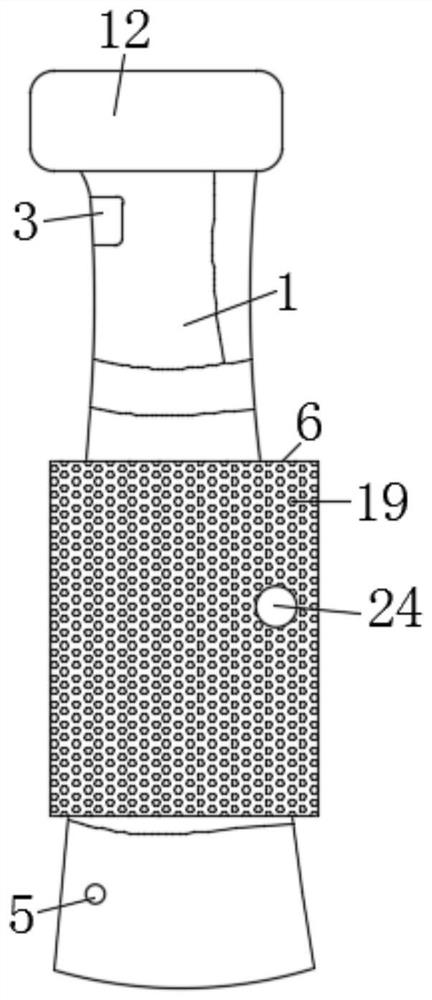

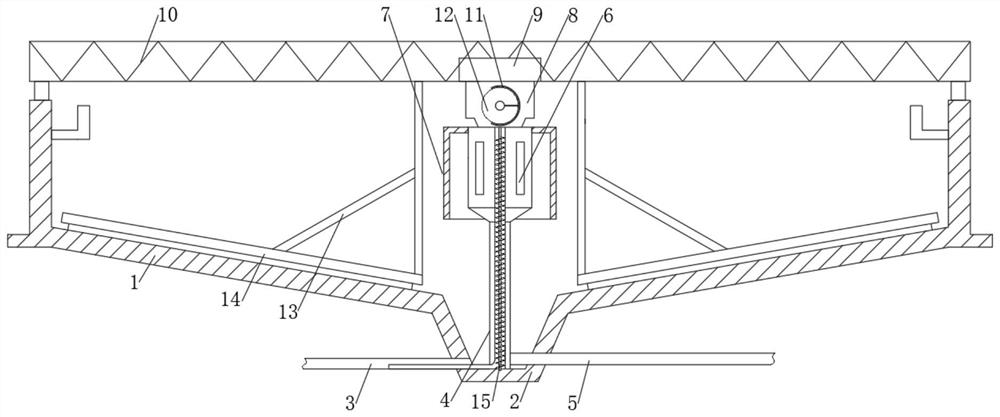

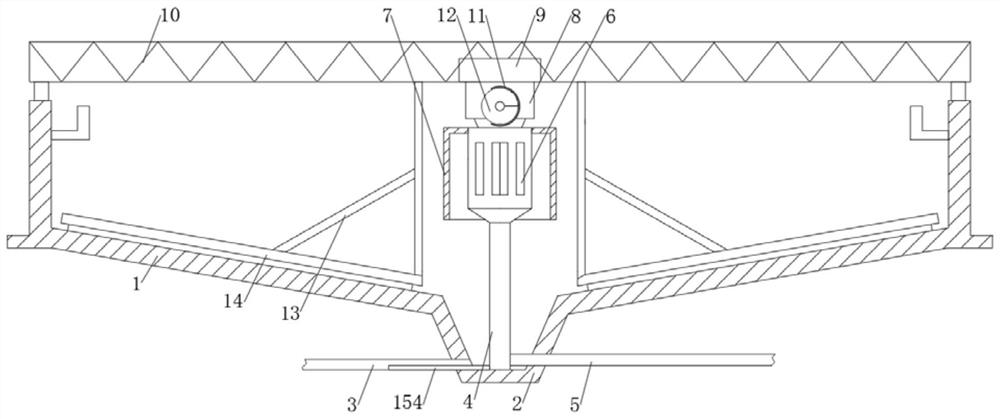

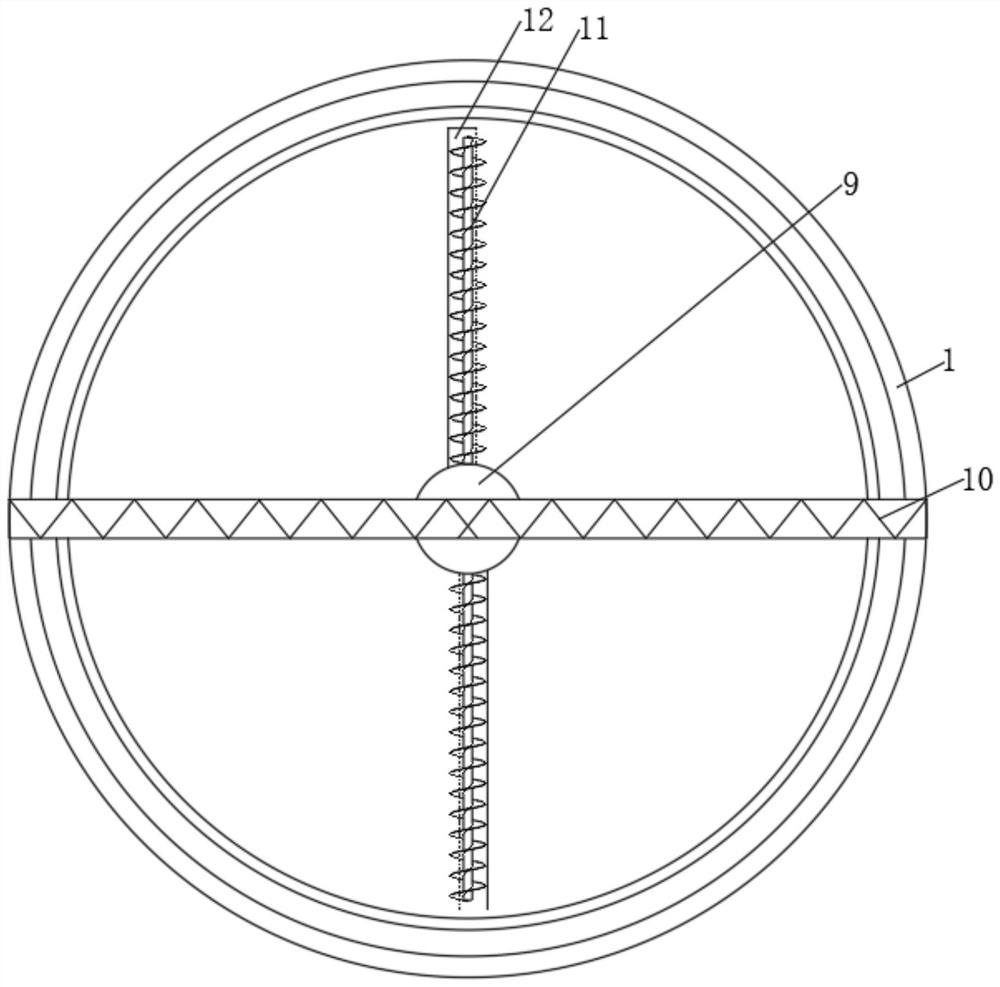

Secondary sedimentation tank suitable for glass processing wastewater treatment

ActiveCN111790186AReduce gapThere will be no gapsSettling tanks feed/dischargeSedimentation settling tanksSludgeSewage treatment

The invention relates to the technical field of sewage treatment equipment, and discloses a secondary sedimentation tank suitable for glass processing wastewater treatment. The sewage treatment tank comprises a tank body, a sludge hopper is arranged at the bottom of the tank body, a sludge outlet pipe is fixedly mounted on one side of the sludge hopper, a central cylinder is fixedly connected to the middle of the sludge hopper, a water inlet pipe is fixedly connected to one side of the bottom of the central cylinder, and a water outlet pipe is fixedly connected to the upper end of the centralcylinder. A mud scraping device is arranged; when the mud scraping device is mounted; a mud scraping plate clings to the tank bottom under the action of an air bag; a gap is prevented from appearing between the mud scraping plate and the tank bottom; incomplete mud scraping is generated, the separation efficiency is influenced, meanwhile, when the sludge scraping plate scrapes sludge, the air baghas a downward compression tendency under the static pressure of water in the tank, and after the sludge scraping plate is abraded, the air bag extrudes the sludge scraping plate, so that the sludgescraping plate is always tightly attached to the bottom of the tank, the situation that a gap exists between the sludge scraping plate and the tank bottom is avoided, and the problems of incomplete sludge scraping and poor sludge scraping effect are avoided.

Owner:来安县华阳玻璃制品有限公司

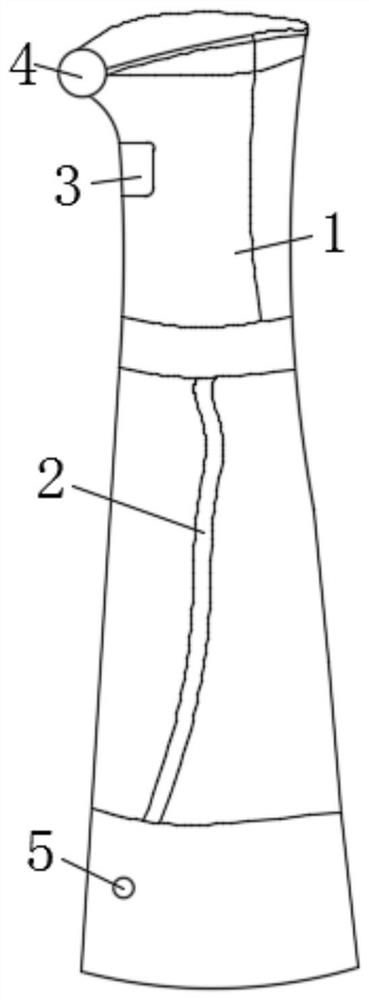

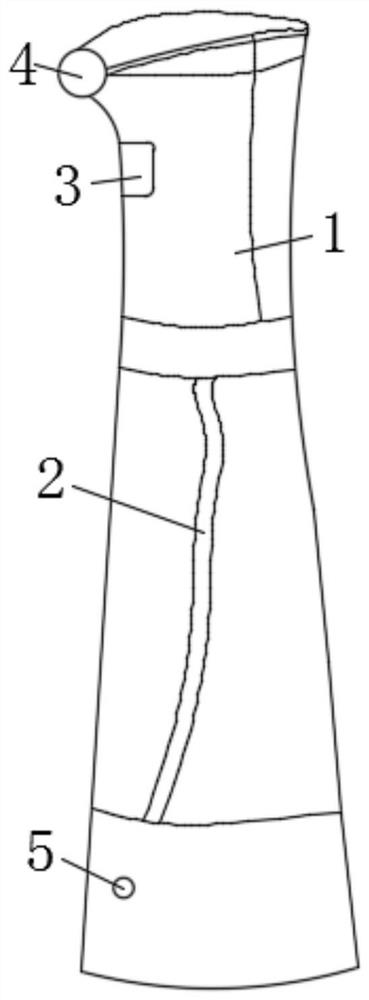

Spray disinfector and using method thereof

The invention discloses a spray disinfector and a use method thereof. The spray disinfector comprises a bottle body, a suction pipe, a spray head switch, a nozzle and a starting switch, and also comprises an annular plate arranged on the outer side of the bottle body in a sleeving manner. Symmetrically arranged clamping plates are movably connected in the annular plate, and containing grooves areformed in the side walls, opposite to the bottle body, of the clamping plates. Cooling pipes are detachably connected into the containing grooves and communicate with one another, extrusion plates arefixedly and elastically connected to the inner side walls of the cooling pipes, the extrusion plates are movably connected with the inner side walls of the cooling pipes in a sealed mode, and pressing blocks are fixedly connected to the outer side walls of the cooling pipes. The top of the bottle body is sleeved with a protection cover, and a charging box is detachably connected to the protectioncover. By means of the spray disinfector and the use method thereof, it is convenient to shake liquid in the bottle body evenly, and convenience is brought to workers.

Owner:YUYAO RIKE ELECTRIC

A secondary settling tank suitable for glass processing wastewater treatment

ActiveCN111790186BReduce gapThere will be no gapsSettling tanks feed/dischargeSedimentation settling tanksSludgeSewage treatment

The invention relates to the technical field of sewage treatment equipment, and discloses a secondary sedimentation tank suitable for glass processing wastewater treatment, including a tank body, a sludge bucket is provided at the bottom of the tank body, and one side of the sludge bucket is fixed A mud outlet pipe is installed, a central cylinder is fixedly connected to the middle of the sludge hopper, a water inlet pipe is fixedly connected to one side of the bottom of the central cylinder, and a water outlet pipe is fixedly connected to the upper end of the central cylinder. Through the setting of the mud scraping device, when the mud scraping device is installed, the mud scraper will stick to the bottom of the pool under the action of the air bag to prevent the gap between the mud scraper and the bottom of the pool, resulting in incomplete scraping and affecting the separation efficiency. When the mud scraper scrapes the sludge, the air bag has a tendency to compress downward under the static pressure of the water in the pool. When the mud scraper is worn out, the air bag will squeeze the mud scraper so that the mud scraper is always close to the pool To ensure that there will be no gap between the mud scraper and the bottom of the pool, and avoid the problems of incomplete scraping and poor mud scraping effect.

Owner:来安县华阳玻璃制品有限公司

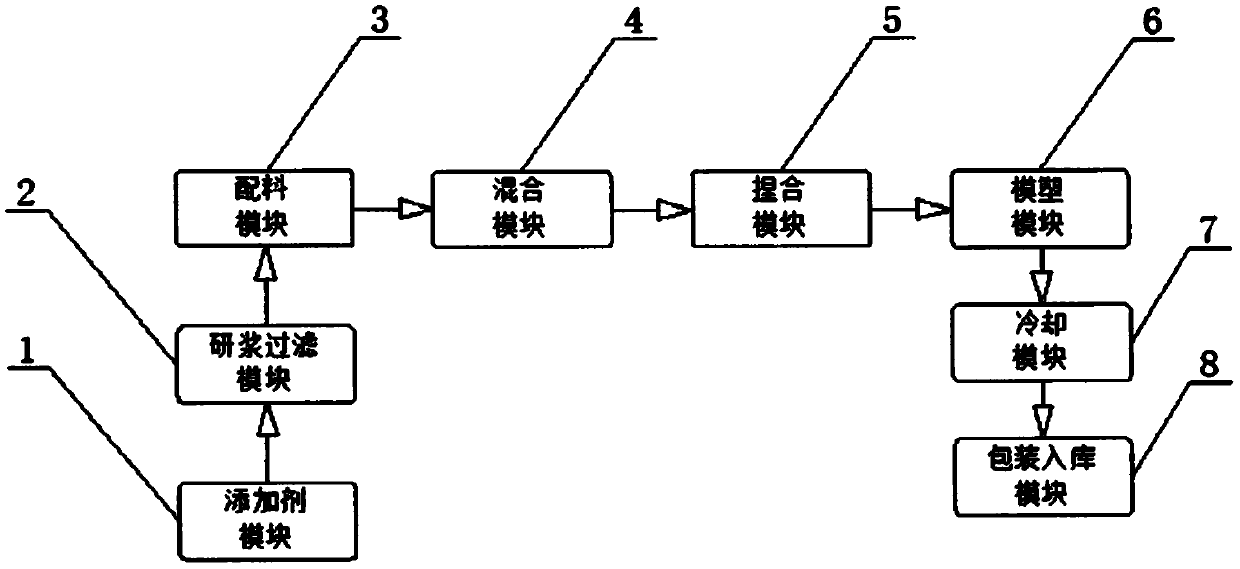

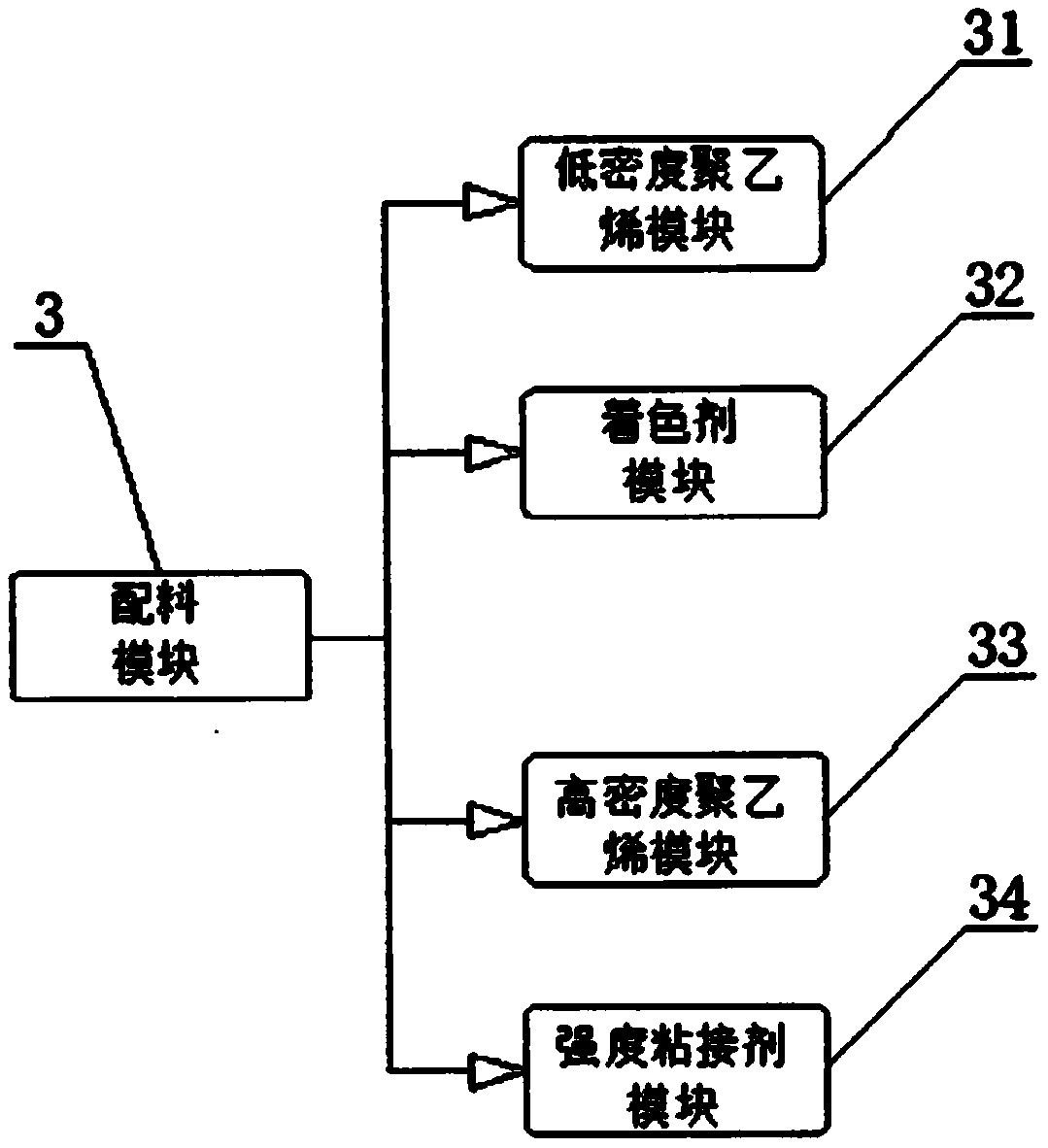

Modified nano high-strength polyethylene films

InactiveCN110655704AWell mixedEnhanced interactionFlat articlesLow-density polyethylenePolymer science

The invention discloses modified nano high-strength polyethylene films which are prepared by combining the following process modules, wherein the process modules comprise an additive module, a pulp grinding and filtering module, a batching module, a mixing module, a kneading module, a molding module, a cooling module and a packaging and warehousing module; the output end of the additive module isthe pulp grinding and filtering module; the pulp grinding and filtering module can receive materials from the interior of the additive module; the strength adhesive module is added in the production process of the polyethylene films; therefore, under the action of the strength adhesive module, the high-density polyethylene module and the low-density polyethylene module can be better mixed and interacted; the inner core operation is carried out after the mixing process, so that the produced polyethylene films can be connected with each other more tightly, the phenomenon of gaps is avoided, andthe strength can be better enhanced by using the strength adhesive module.

Owner:HAN YIN SUZHOU ECO MATERIALS TECH CO LTD

a luminous mask

The invention discloses a light-emitting mask comprising a light-emitting component and a mask body and further comprising a framework and ear hooks installed on the framework, wherein the mask body is a light guide board fixed to the framework; the light-emitting component is installed on the framework; the light-emitting component corresponds to the light guide point on the light guide board; the framework comprises an inner frame and an outer frame which are buckled with each other; the light guide board is fixed between the inner frame and the outer frame. The light guide board can cover the whole face, only a strip-shaped framework part of the whole light guide board is shielded, the shielded part of the light guide board is the eye part of the user, and the user experience is good; the light guide board does not make direct contact with the face, frequent cleaning is not required, use is convenient and rapid, and sanitation is achieved; heat is diffused out through cooling holes and cooling fins; the whole outer frame and the light guide board can be better attached to each other through a pressing strip, the sealing performance is better, gaps are avoided, light is not leaked easily, and water or dust does not enter the light-emitting mask easily.

Owner:SHANGHAI HONGYE PHOTOELECTRIC TRADING

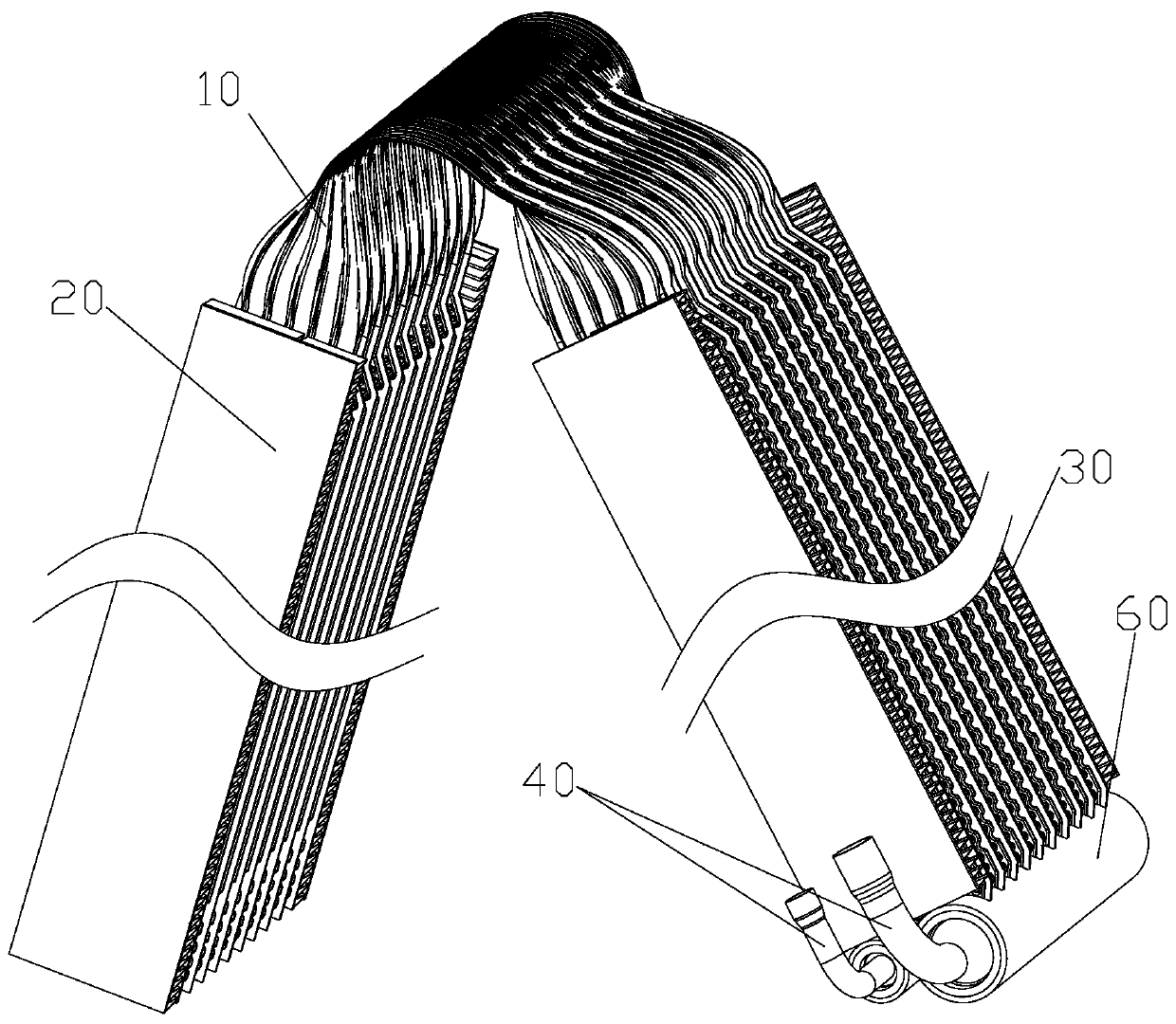

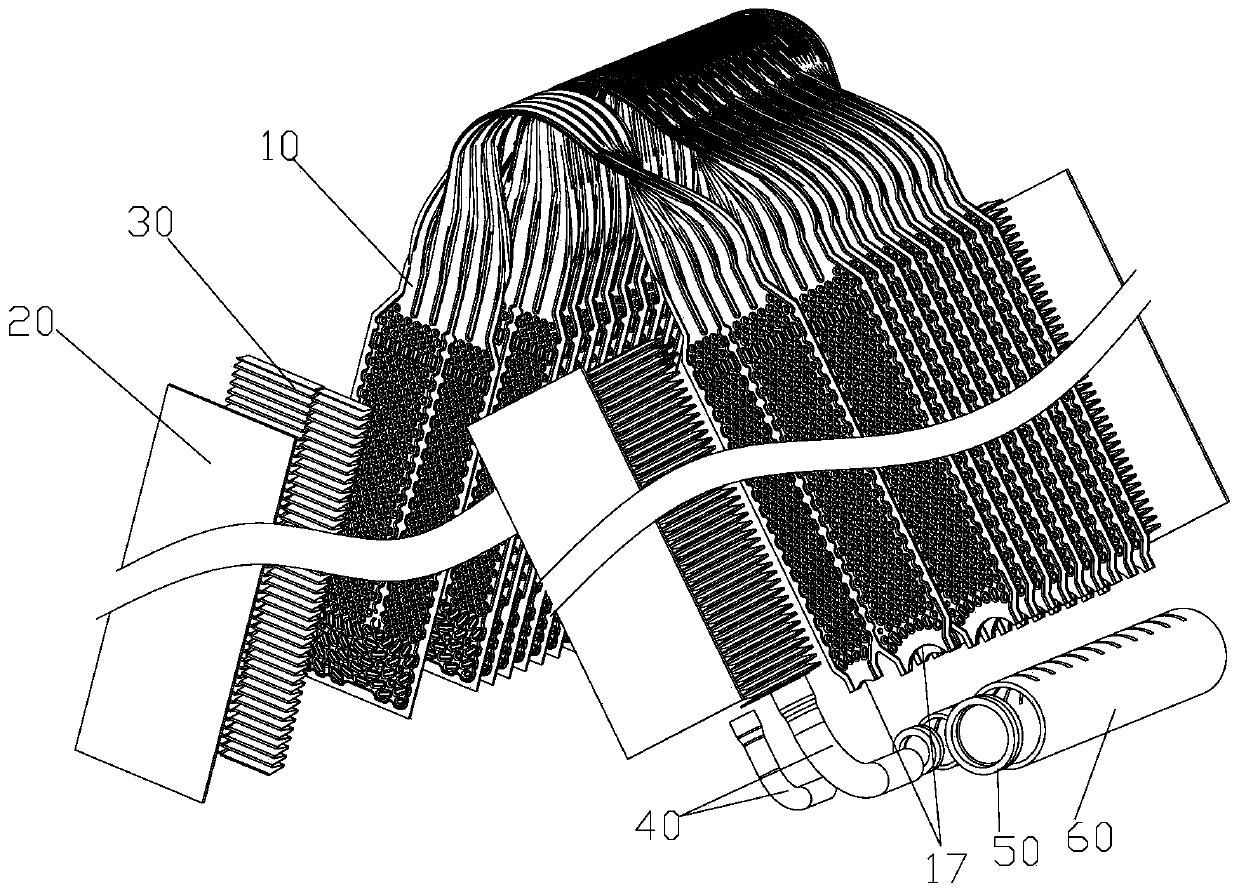

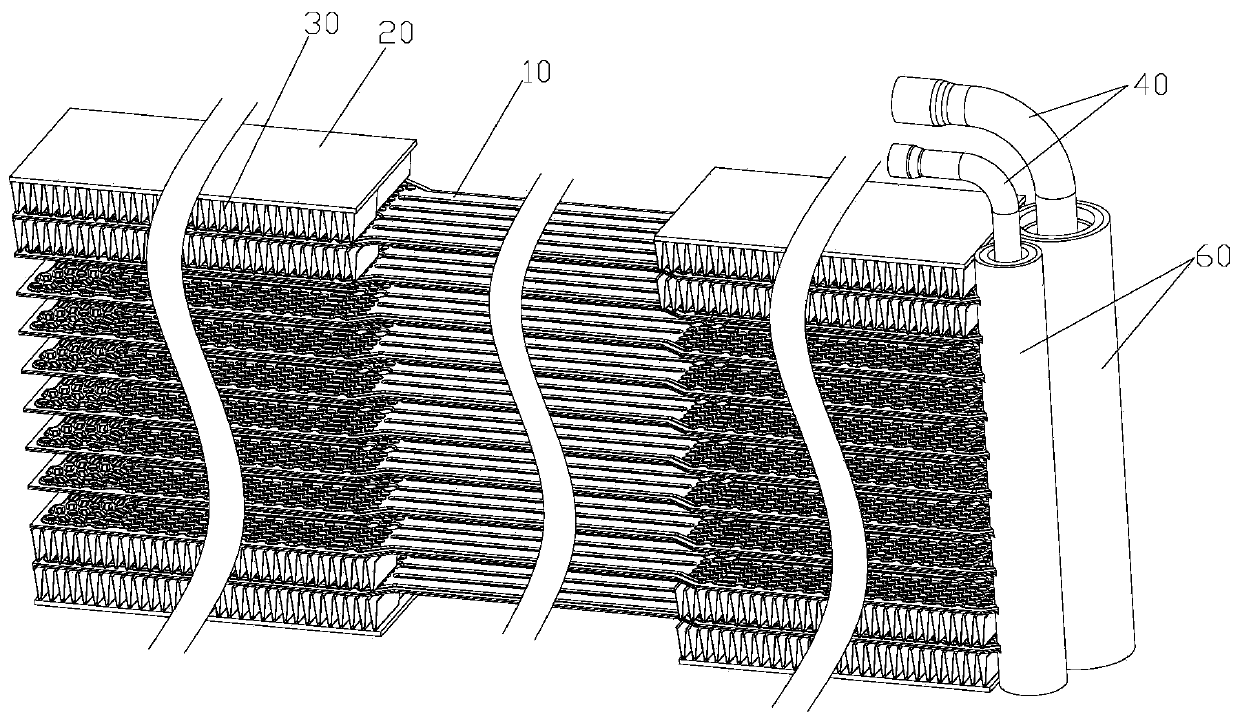

Flat tube and heat exchanger

PendingCN111442662AEasy to reverseNot easy to damageStationary conduit assembliesHeat exchanger casingsEngineeringMechanical engineering

The invention provides a flat tube and a heat exchanger. The flat tube comprises a body; a separation part is arranged in the width direction of the body; the separation part is used for separating the body into a first channel and a second channel; a first end of the first channel communicates with a first end of the second channel; the body comprises at least two straight sections; every two adjacent straight sections are connected through a twisting section; and the width of the twisting sections is not larger than that of the straight sections. When the flat tube is actually bent, only one-time bending is needed at the twisting sections, only one row of core bodies is generated after twisting, the phenomenon that gaps exist between a front row of core bodies and a rear row of core bodies does not occur, the structure is compact, the space utilization rate is high, and the bending operation is convenient.

Owner:ZHEJIANG DUNAN THERMAL SCI & TECH

A spray sterilizer and method of use thereof

ActiveCN112387446BImprove comfortEasy to moveSingle-unit apparatusStructural engineeringMechanical engineering

The invention discloses a spray sterilizer and its use method, which comprises a bottle body, a suction pipe, a nozzle switch, a nozzle and a start switch, and also includes an annular plate sheathed on the outside of the bottle body. The clamping plate is provided with a holding groove on the side wall of the clamping plate opposite to the bottle body, and a cooling pipe is detachably connected in the holding groove, and the cooling pipes communicate with each other, and the inner side wall of the cooling pipe An extruding plate is fixed and elastically connected, and the extruding plate is sealed and movable connected with the inner wall of the cooling pipe, and a compression block is fixedly connected to the outer wall of the cooling pipe; the top of the bottle body is provided with a protective Cover, the protective cover is detachably connected with a charging box, and the present invention is convenient to shake the liquid in the bottle evenly, which brings convenience to the staff.

Owner:YUYAO RIKE ELECTRIC

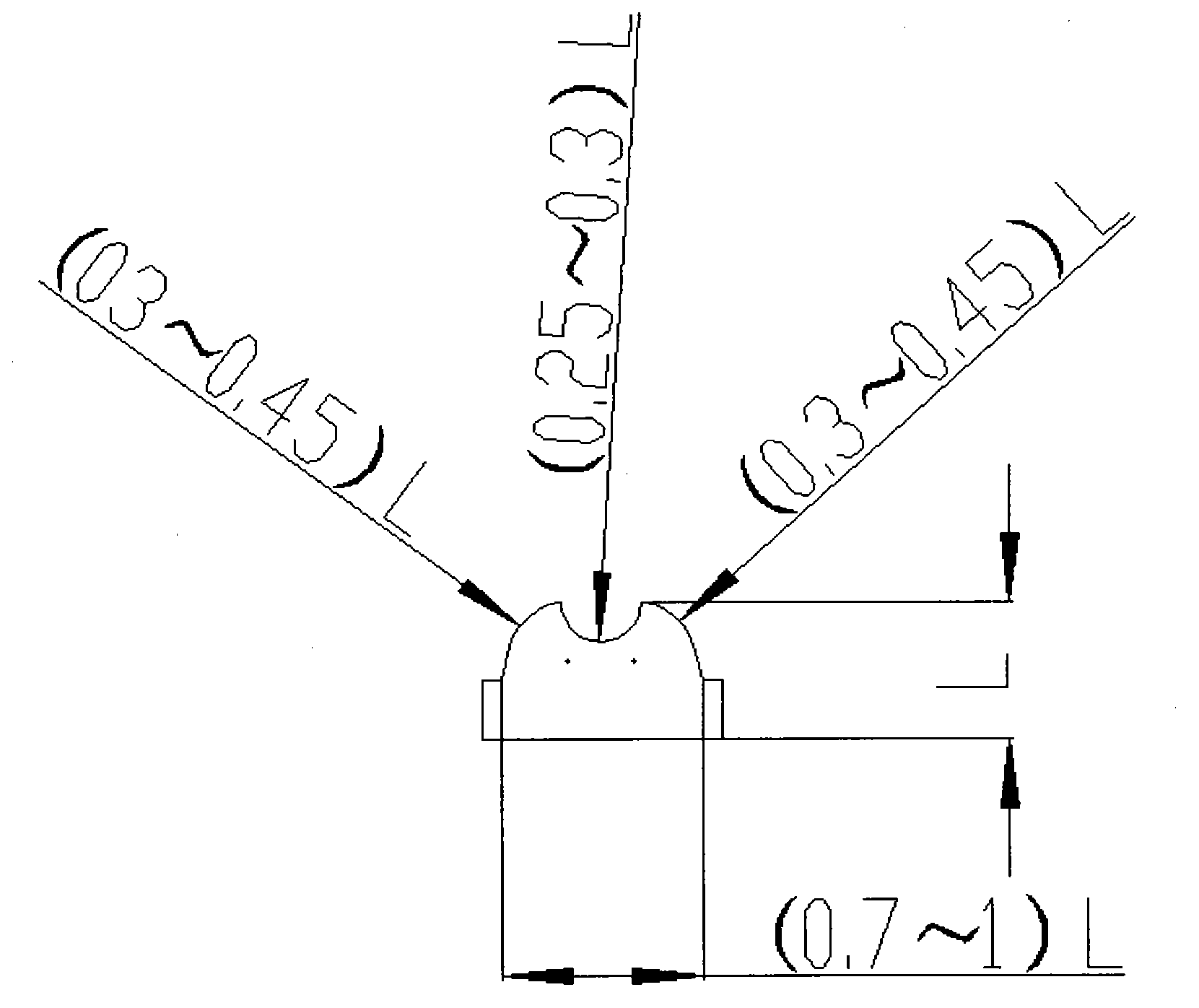

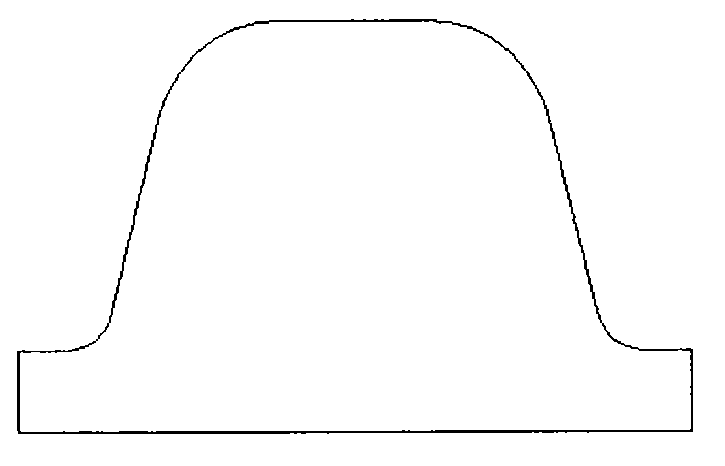

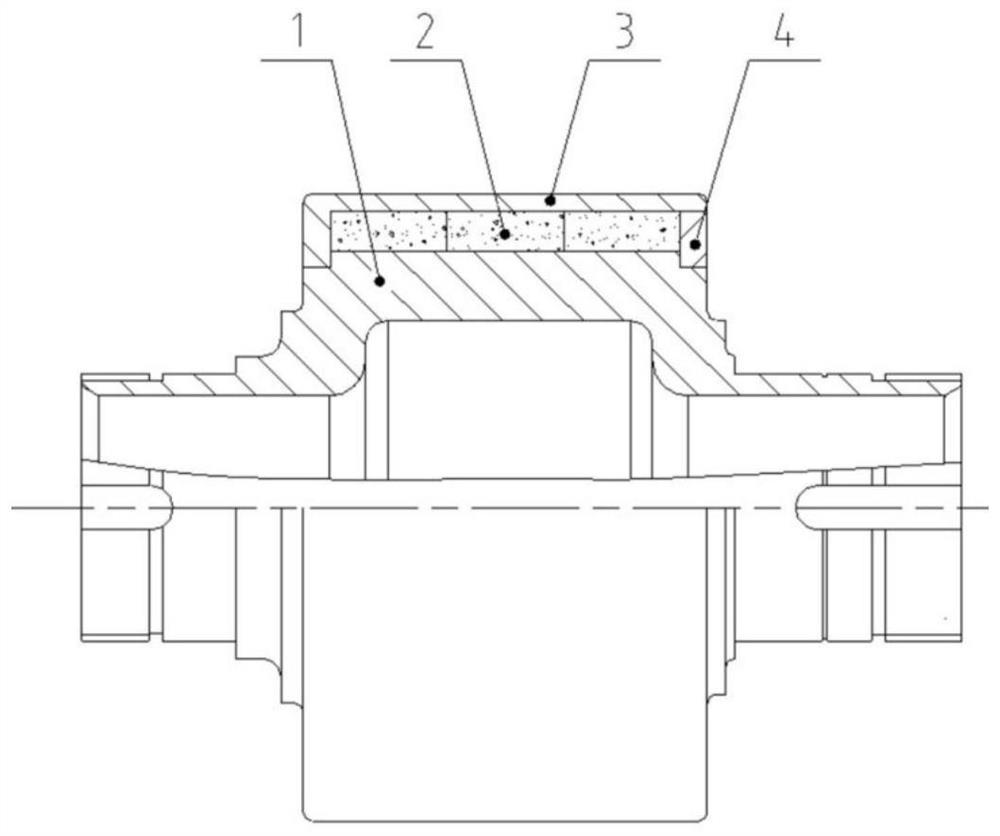

Filter core pressing sealing structure in high-temperature and high-pressure environment

InactiveCN103437920AGuaranteed room for expansionThere will be no gapsEngine sealsAir cleaners for fuelHigh resistanceEngineering

The invention belongs to the technical field of vehicle filter cores, and particularly relates to a filter core pressing sealing structure in high-temperature and high-pressure environment. In order to realize the goal that a filter core pressing sealing mechanism can adapt to the high-temperature and high-pressure environment, the filter core pressing sealing structure in the high-temperature and high-pressure environment provided by the invention is characterized in that the appearance of the pressing sealing structure is in a wedge shape, the top of the wedge-shaped pressing sealing mechanism is provided with a semicircular groove, the deformation quantity of the wedge-shaped pressing sealing structure is 2 to 3mm, and the wedge-shaped pressing sealing structure is made of silicon gel materials with the highest resistance temperature being 200 DEG C. Therefore, the filter core pressing sealing structure has the advantages that the process is simple, the sealing is reliable, the cost is low, and the resistance on the high-temperature and high-pressure environment can be realized.

Owner:CHINA NORTH VEHICLE RES INST

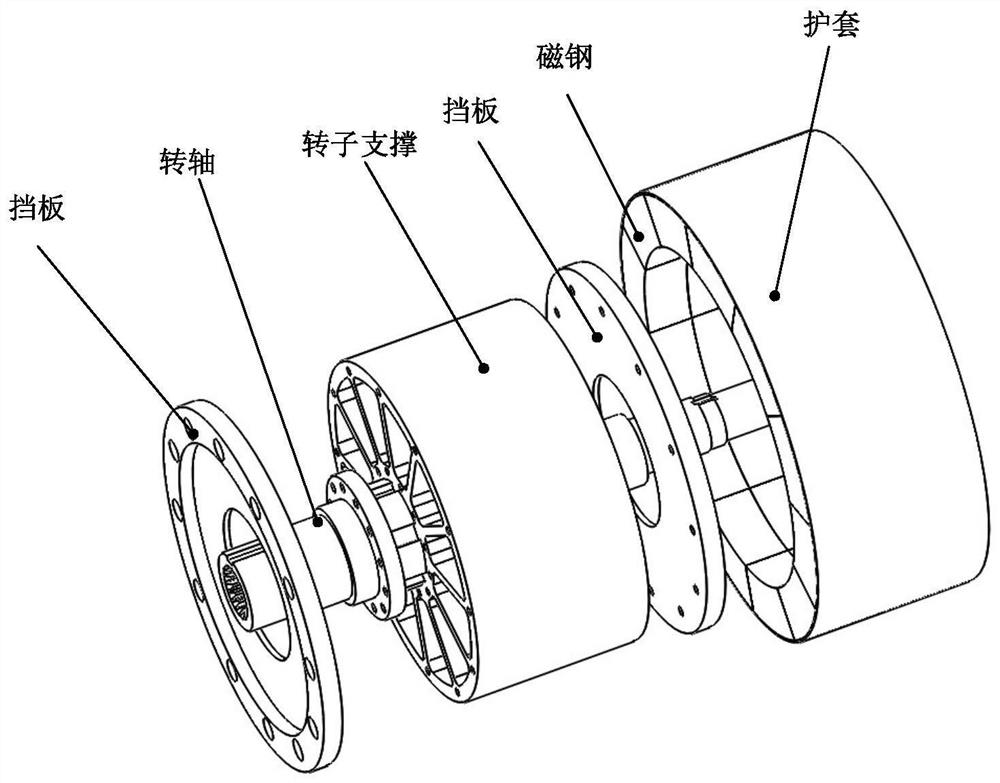

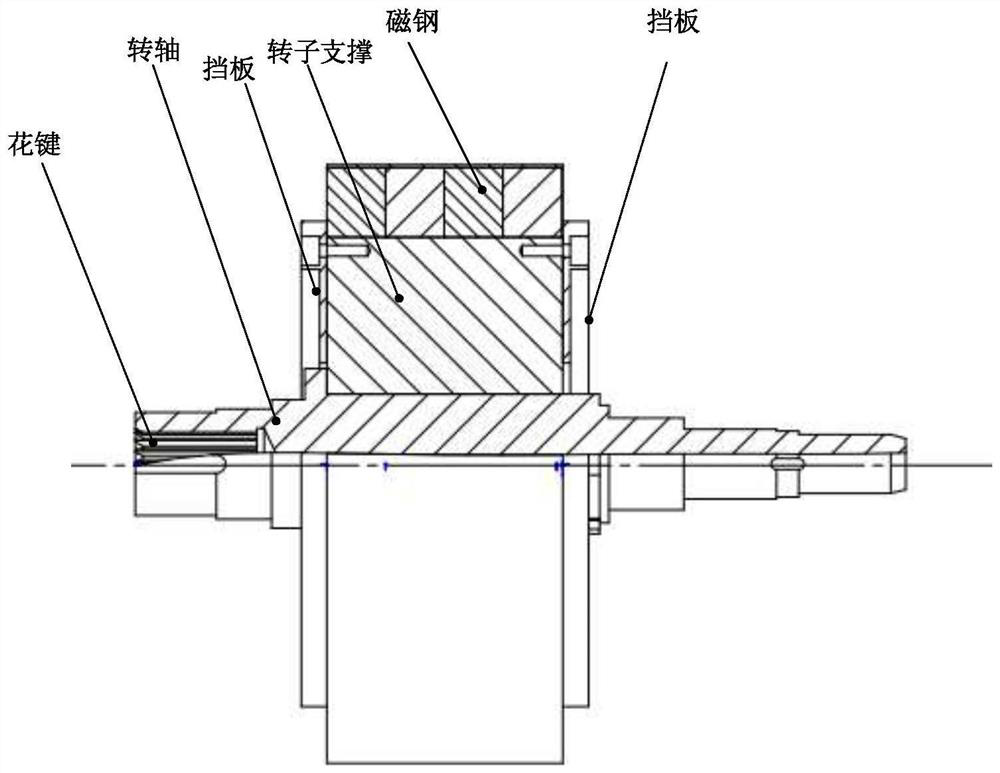

A permanent magnet motor rotor resistant to high temperature and low pressure environment

ActiveCN109980817BThere will be no gapsFast heat conductionMagnetic circuit rotating partsInterference fitElectric machinery

The invention provides a permanent magnet motor rotor capable of resisting to high temperature and a low air pressure environment. The rotor comprises a rotating shaft, a rotor support, magnetic steel, a baffle and a sheath. The rotating shaft is connected with the rotor support through multiple keys, and the baffle is fixed at two sides of the rotor support; the magnetic steel is fixed on the rotor support, and the sheath fixes the magnetic steel through interference fit; when the permanent magnet motor rotor works, when the temperature rises, no gap is arranged between the rotor support andthe rotating shaft, so that heat transfer characteristics are good, and the temperature is brought out in time. Flat keys and the rotor support are integrated into one body to present the structure ofthe inner circular teeth of the rotor support, the phenomenon of gaps due to the connection of the flat keys is avoided, and good heat conduction effect can be kept. The invention provides a structure of connection of the rotating shaft and the rotor support through multiple keys, a plurality of keyways are arranged on the rotating shaft, teeth are arranged on the rotor support so that the rotorsupport is expanded to tighten the key connection and the heat conduction performance is not decreased so as to conduct the temperature of the magnetic steel of the rotor and reduce the risk of the high-temperature demagnetization.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A method of solid waste gasification power generation

ActiveCN112029534BImprove recycling effectExtension of timeInternal combustion piston enginesGasification processes detailsThermodynamicsProcess engineering

The invention provides a solid waste gasification power generation method, which relates to the technical field of waste power generation. The solid waste gasification power generation method is completed by a solid waste gasification power generation device, thereby realizing solid waste gasification power generation. The invention solves the problems that the existing waste gasification power generation method has poor heat recovery effect when waste is burned, and cannot recover heat in multiple layers and angles.

Owner:赵明星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com