Variable-rate mist spraying system and control method

A spray system and variable technology, applied in the fields of trapping or killing insects, applications, animal husbandry, etc., can solve problems such as poor droplet distribution quality, low pesticide utilization rate, pesticide loss, etc., to ensure uniformity, large size, etc. The effect of improving the utilization rate of pesticides and expanding the range of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

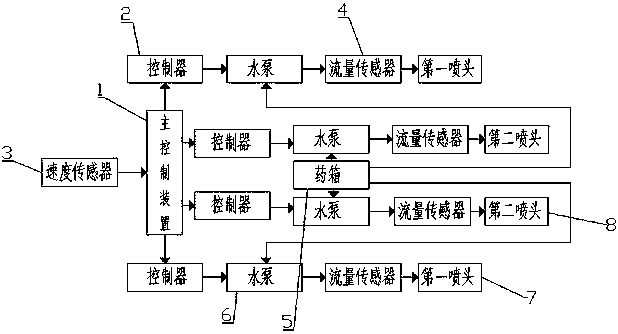

[0027] Refer to attached figure 1 , the variable spraying system of the present invention is a portable system that can be placed on different sprayers and vehicles, which includes a control module, a measurement module and a spray module,

[0028] The control module includes a main control device 1 and a controller 2. The main control device 1 is used to receive the measurement data of the measurement module and send the flow control signal to the controller 2. The main control device 1 is preferably a STM32 main control module. Obviously, Can be other conventional control devices known to those skilled in the art, the controller 2 controls the spray flow of the spray module, the controller 2 is a motor drive module, and the motor drive module is used to receive instructions from the main control device 1 and control the water pump 6 Rotating speed,

[0029] The measurement module includes a speed sensor 3 for measuring the walking speed of the walking device and a flow sens...

Embodiment 2

[0039] Continue to refer to the attached figure 1 , the basic structure and principle of this embodiment are basically the same as the first embodiment above, the difference is that the minimum atomization flow values of the first nozzle 7 and the second nozzle 8 are equal, which can also be understood as the first nozzle 7 and the second nozzle 8 The second nozzle 8 is the nozzle of the same type. When the main control device 1 controls the spraying of the above-mentioned nozzles, the nozzle spraying is divided into the following three stages according to the moving speed of the traveling device from low to high.

[0040] (1) When the calculated theoretical spray flow value is less than the maximum atomization flow value of the first spray head 7, the main control device 1 controls the pump body 6 corresponding to the first spray head 7 or the second spray head 8 to stop working through the controller 2, Control the pump body 6 corresponding to the other nozzle to work, and...

Embodiment 3

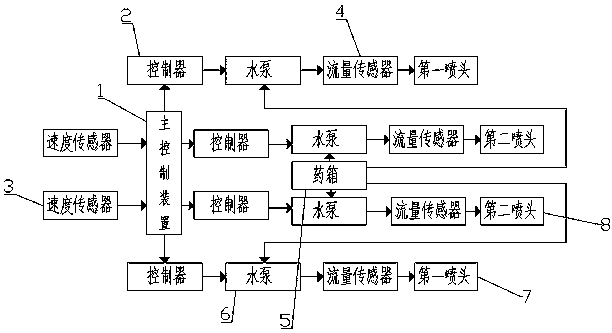

[0044] Refer to attached figure 2 , the basic structure and principle of this embodiment are the same as those of Embodiment 1 or 2 above. The difference is that there are two speed sensors 3, which are respectively arranged near the traveling wheels on both sides of the traveling device, and are used to measure the corresponding side walking Number of rotations.

[0045] In the control method of this embodiment, when the rotation numbers of the traveling wheels on both sides measured by the two speed sensors 3 are consistent, that is, the traveling device travels straight and sprays, and the spraying process of the nozzle is the same as that of the first or second embodiment. When the number of revolutions of the traveling wheels on both sides measured by the two speed sensors 3 is different, that is, the traveling device turns to spray, and the spraying amount of the spraying nozzle on the inside of the steering is smaller than that of the spraying nozzle on the outside, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com