A dust-proof sliding pad for a gear shifter

A shifter and sliding pad technology, which is applied in the field of dust-proof structure of the shifter, can solve the problems of large size of the auxiliary sliding pad, affecting the shifting quality, large layout space, etc., and achieves beautiful appearance, good dust-proof effect, The effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

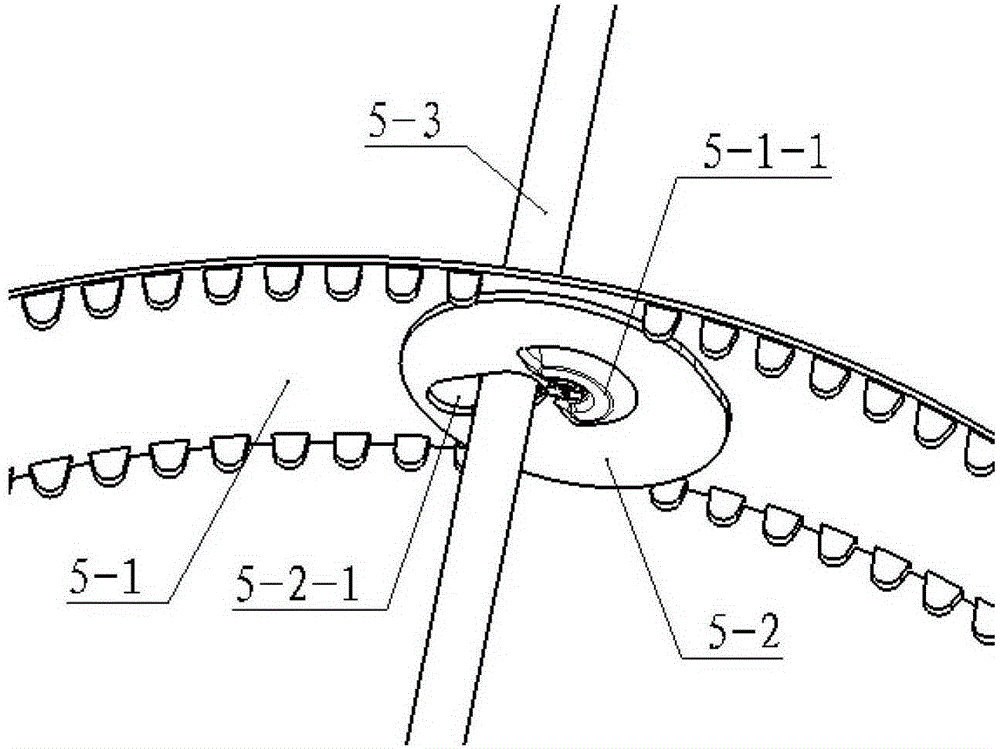

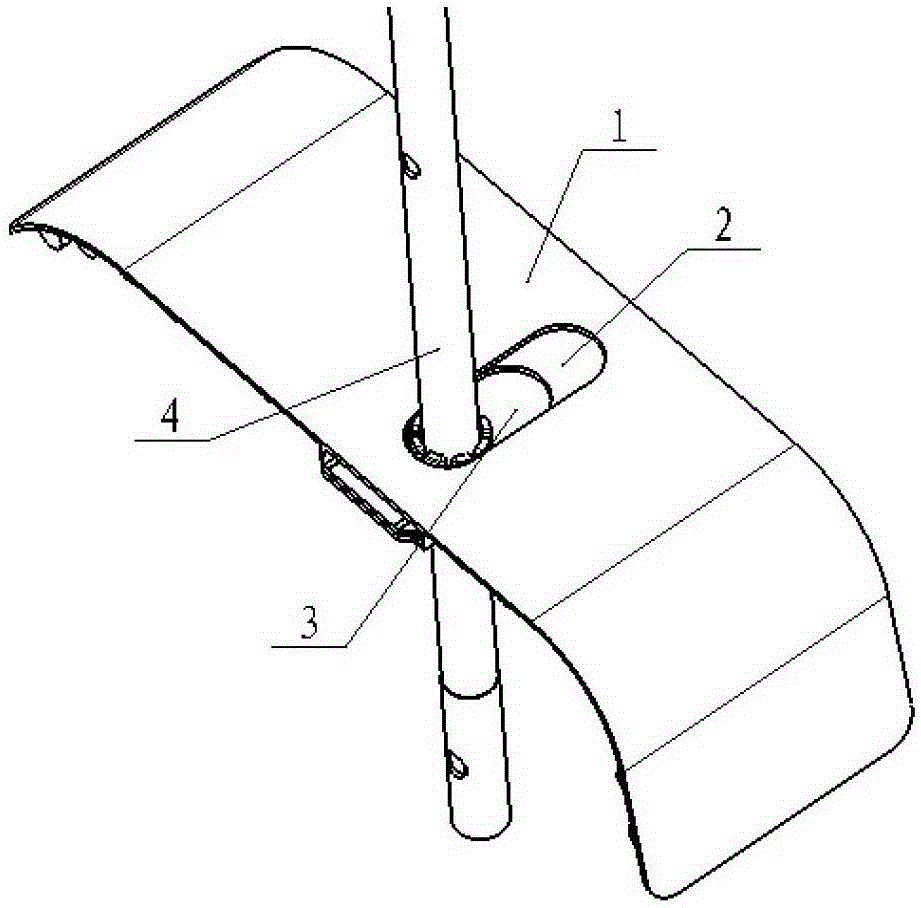

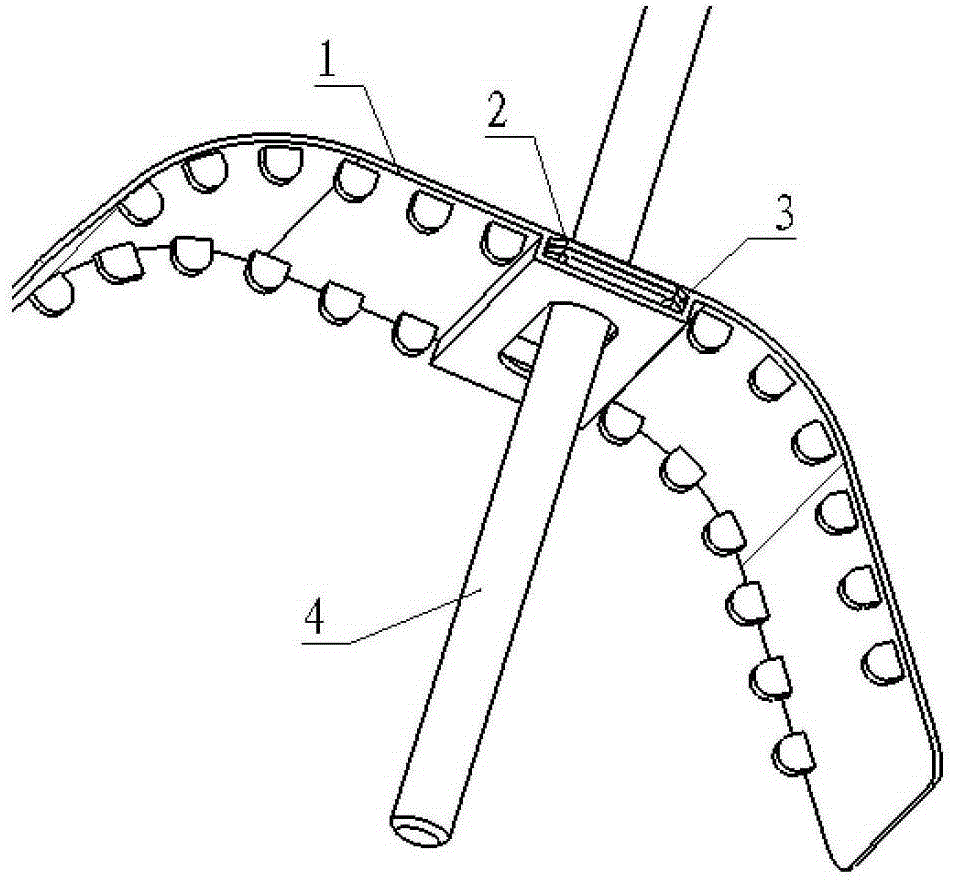

[0016] Such as Figure 2A , Figure 2B shown, combined with Figure 5A : This structure mainly includes the main sliding pad 1, the first auxiliary sliding pad 2, the second auxiliary sliding pad 3 and the shift lever 4. The first pair of sliding pads 2 and the second pair of sliding pads 3 are stacked together from top to bottom and assembled into the chute 1-1 on the back of the main sliding pad 1, and can be left and right in the chute of the main sliding pad 1 slide. The main sliding pad 1, the first auxiliary sliding pad 2 and the second auxiliary sliding pad 3 are assembled with the shift lever 4 through the round hole 3-1 provided on the second auxiliary sliding pad 3, and the left and right rotation of the shift lever passes through the second auxiliary sliding pad 3. The second auxiliary sliding pad 3 can drive the first auxiliary sliding pad 2 to move left and right together; the front and rear rotation of the shift lever 4 can drive the main sliding pad 1 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com