Industrial production method of stranded earphone cord

An earphone cable and twisting technology, which is applied in the production field of twisted earphone cables, can solve problems such as reducing production efficiency, increasing scrap rate, and affecting product use, and achieves the goals of improving production efficiency and yield, eliminating stress, and improving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

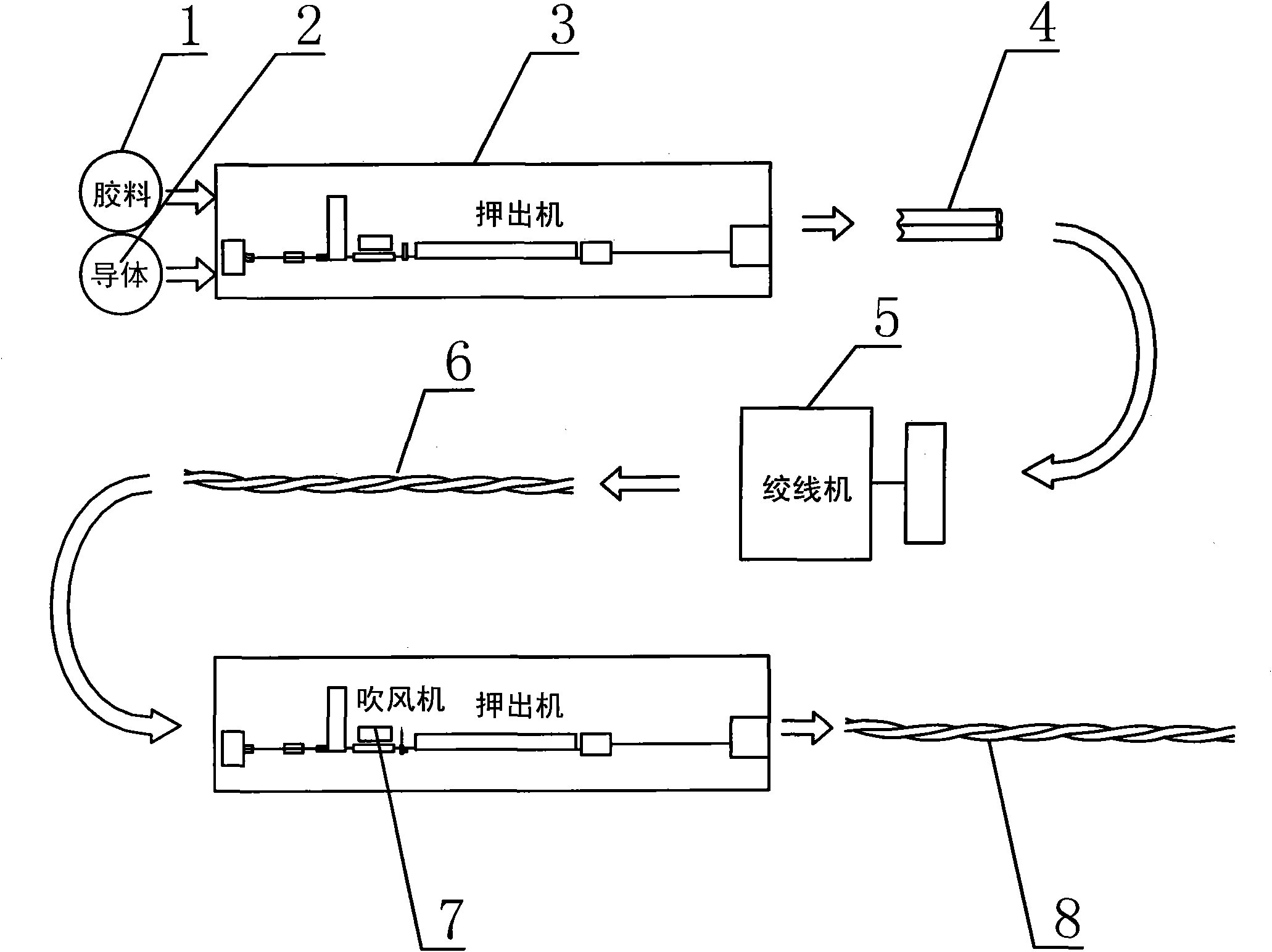

[0019] Below in conjunction with the present invention is further described: the industrial production method of described twisted earphone wire, as figure 1 shown, including the following production steps:

[0020] (1), doubling line extrusion: produce the earphone line doubling line 4 that coating layer 9 is bonded together by extruding machine 3;

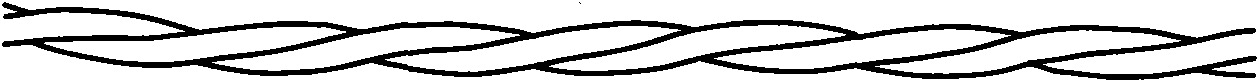

[0021] 2. Stranding: Send the produced parallel wire 4 into the stranding machine 5 for stranding;

[0022] 3. Heating and shaping: heat and shape the twisted wire through the high temperature zone.

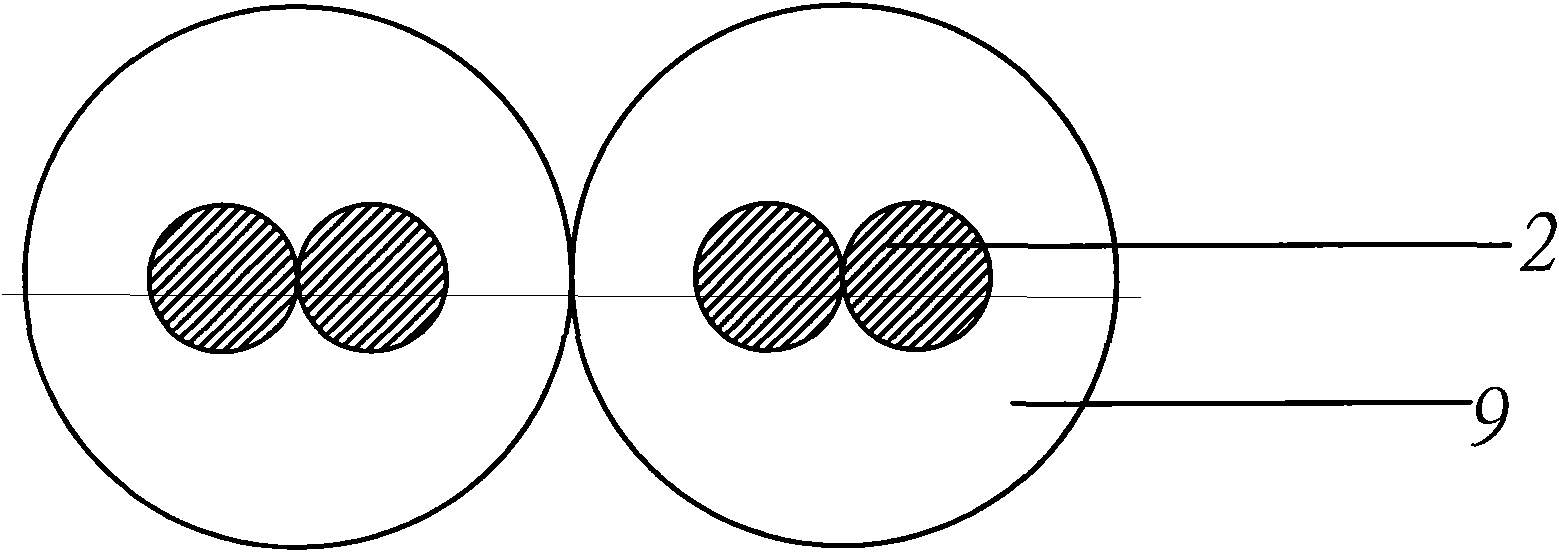

[0023] like figure 2 , in the step 1, two or more metal conductors 2 are arranged for each parallel line 4 .

[0024] The extruder 3 is also called an extruder. The extrusion process is centered on the metal conductor 2. The pellets are converted into a coating layer 9 in the extruder 3 and coated on the outside of the metal conductor 2. The coating layers of the two wires are bonded as The whole body is in the shape of "8", an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com