Multi-component small powder automatic packaging palletizing method

An automatic packaging, multi-component technology, applied in packaging, transportation packaging, transportation and packaging, etc., to achieve the effect of easy on-site use, labor saving, and full automatic control

Inactive Publication Date: 2011-01-05

BEIJING UNITED FOUND TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Does not require manual participation in any action

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

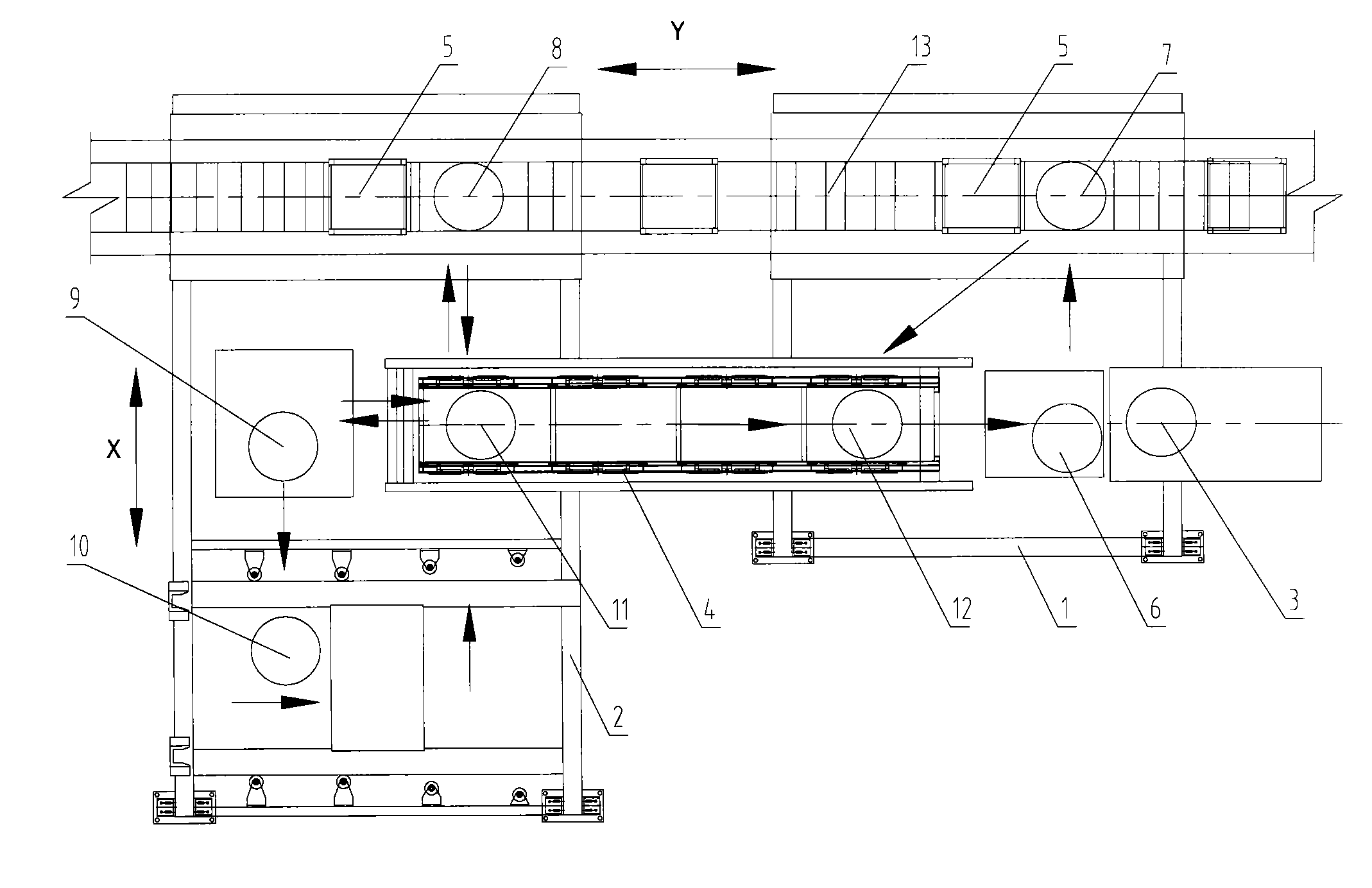

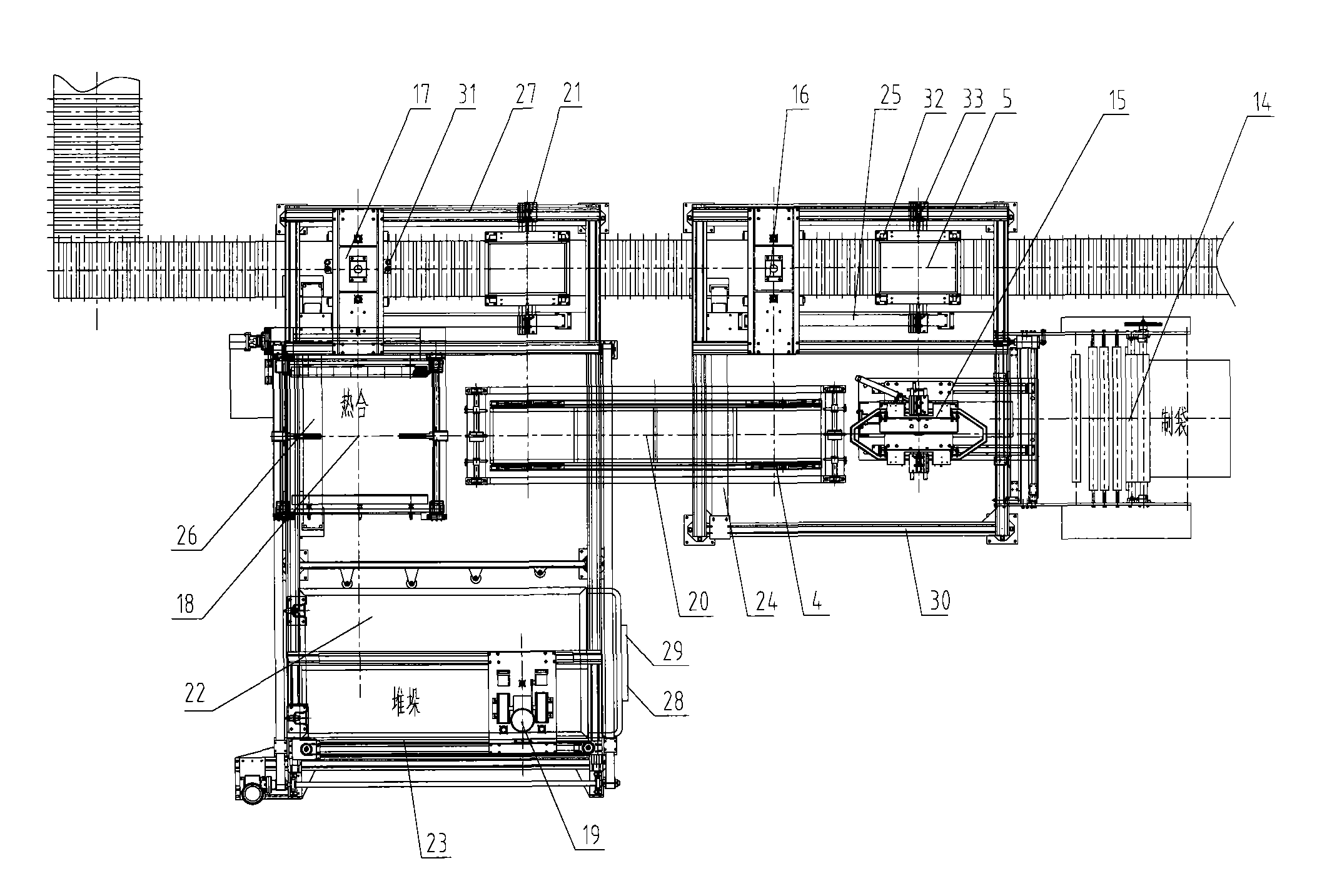

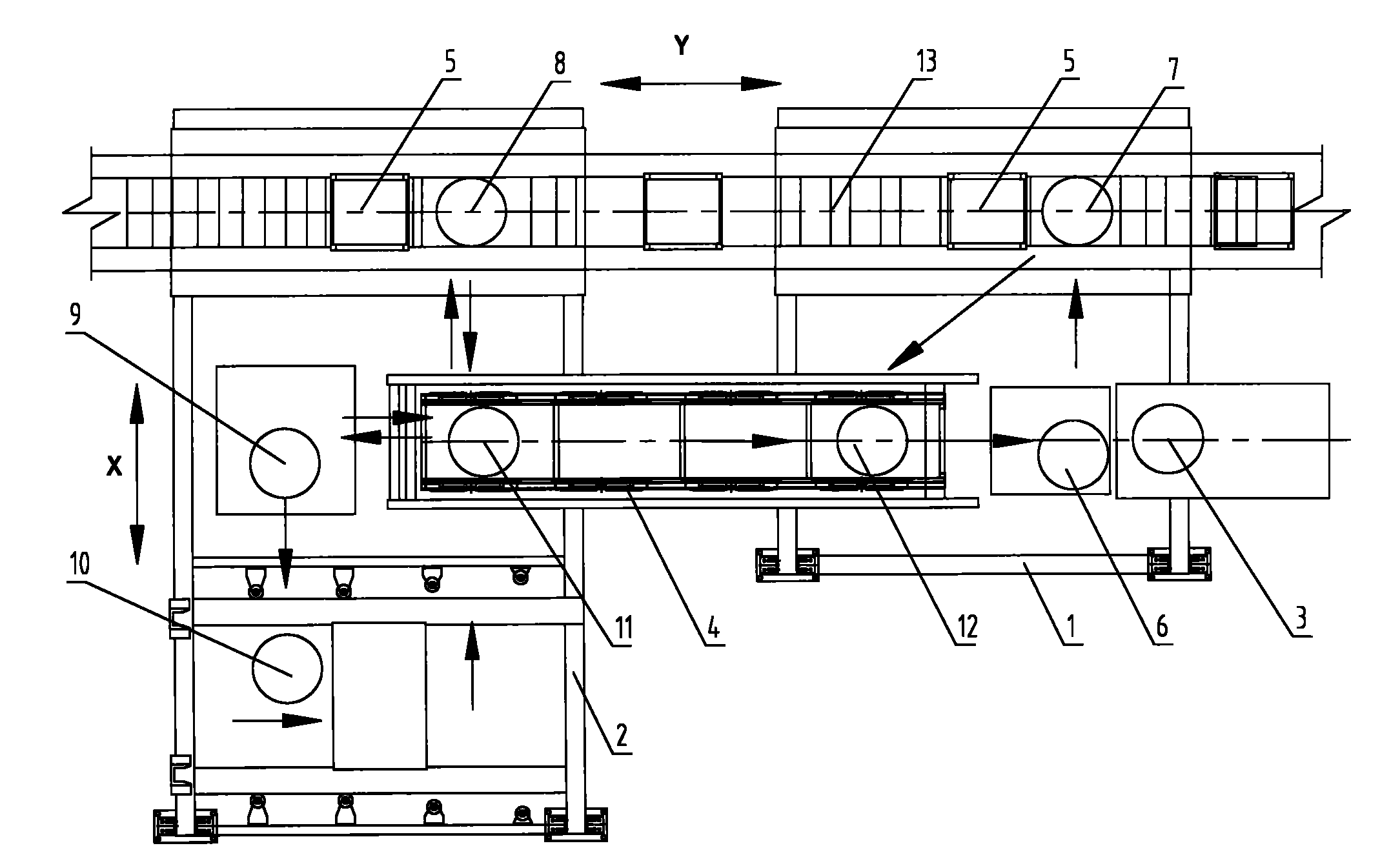

The invention relates to a multi-component small powder automatic packaging palletizing method, belonging to a small powder scale automatic weighing batching apparatus. The method changes the overall processes of putting plastic bag into a charging basket, taking out pockets, closing bag mouths, palletizing the pockets into a storing vehicle before mixing former rubber, during matching various small powders according to the formulation into the full mechanical automation. The method is implemented by the following devices: a bag machine 14, a plastic bag clamping unit 4, a special pocket 5, aclamping unit actuating device 20, a transmitting bag and opening bag mouth device 15, a putting bag device, a taking bag device, a heat seal capper 18, a stack device, a pocket positioning device 21, an empty pocket positioning device 33, a pneumatic control system, an electronic control system and an PLC program control system.

Description

Multi-component small material automatic packaging stacking method technical field The invention relates to a method for automatic packaging and stacking of small materials, in particular to a method for automatic packaging and stacking of multi-component small materials after mixing various small materials (auxiliary agents) according to the formula before rubber mixing. Background technique The known small material scale automatic weighing and batching device is a common equipment for mixing various small materials (auxiliaries) according to the formula before the rubber used in rubber products is mixed. Various small materials are sequentially put into moving plastic bags from their respective storage hoppers according to different proportions for standby. The usual practice of this equipment is to manually put plastic bags in a square or garden-shaped material basket at the entrance of the automatic weighing and batching system of small material scales. Then the mater...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B1/32B65B43/00B65B43/46B65B51/10B65B61/28

Inventor 不公告发明人

Owner BEIJING UNITED FOUND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com