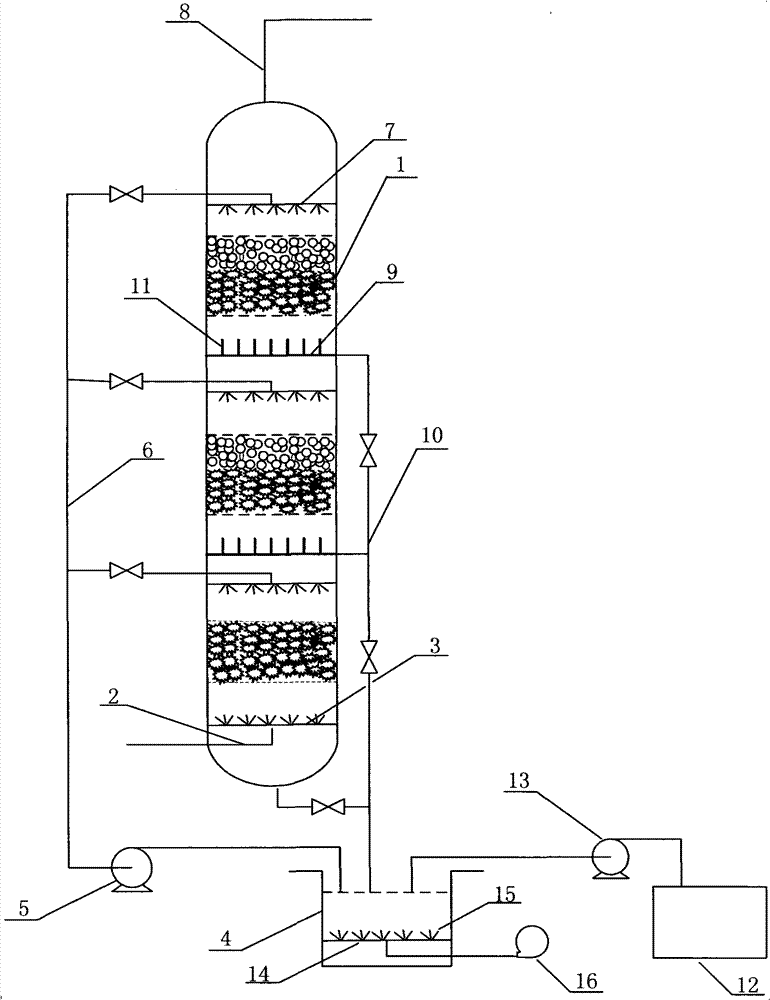

Deodorizing device and deodorizing method of bio-trickling filtration tower

A biological trickling filter tower, deodorization technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of long operation period, plugging packing layer, etc., achieve low resistance, increase quantity, and improve impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

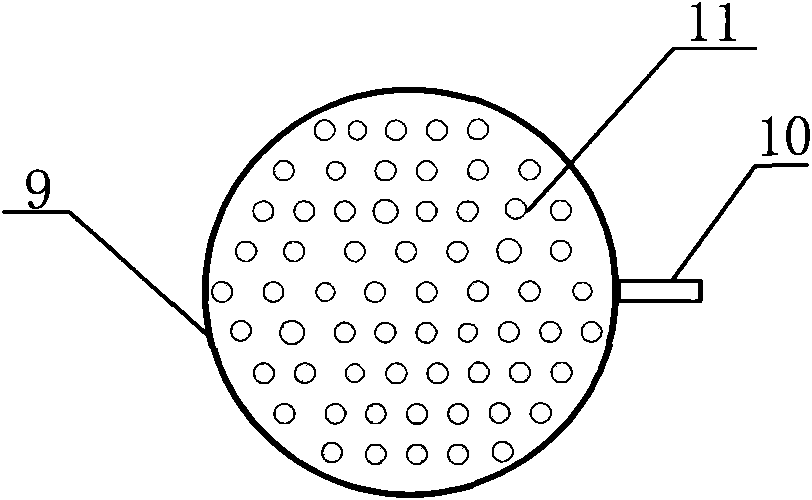

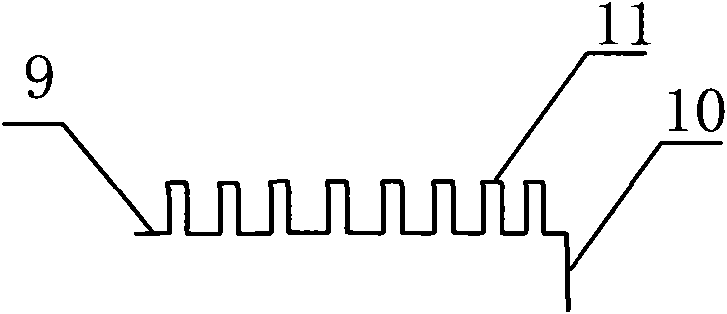

Method used

Image

Examples

Embodiment

[0033] Taking a petrochemical sewage plant as an example, it mainly treats rubber wastewater and ethylene wastewater. The wastewater treatment process produces a large amount of malodorous gas, and the odor pollutant is mainly composed of hydrogen sulfide 100-250mg / m 3 , Methyl mercaptan 4~12mg / m 3 , Volatile organic gas 600~1400μg / mg, and the residence time of malodorous gas in the biological trickling filter device is 30 seconds. The temperature changes with the change of the ambient concentration, and the range of change is 8-36°C. The test runs continuously and stably for 1 year.

[0034] Figure 4 It is the diagram of resistance variation during the operation of the biological trickling filter tower of the embodiment. Such as Figure 4 As shown, the pressure drop of the bio-trickling filter gradually stabilized after continuous spraying for 5 days, and the resistance of the bio-trickling filter remained at about 2000Pa.

[0035] Figure 5 It is the effect diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com