Cold box core shooting device

A cold box and core box technology, applied in the direction of valve devices, lift valves, mechanical equipment, etc., can solve the problems of affecting the stability of the equipment, increasing the cleaning workload, and easy to stick to the molding sand, so as to reduce daily maintenance work, Improve the stability of equipment and avoid the effect of sandblasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

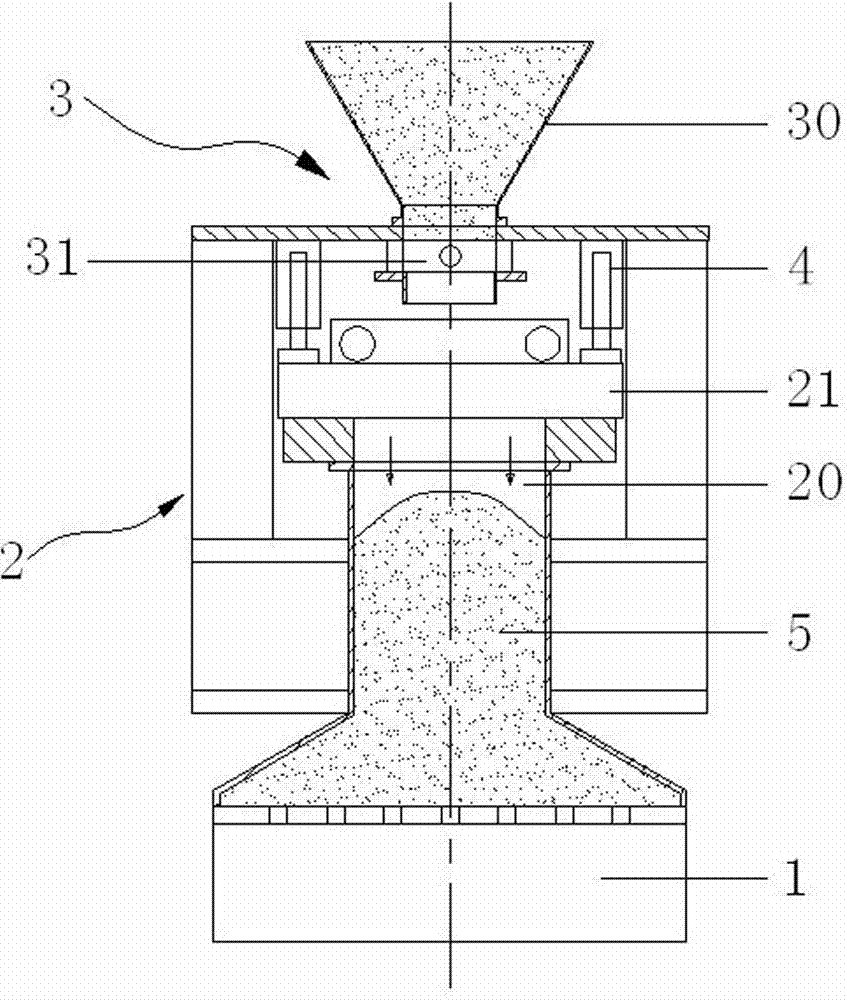

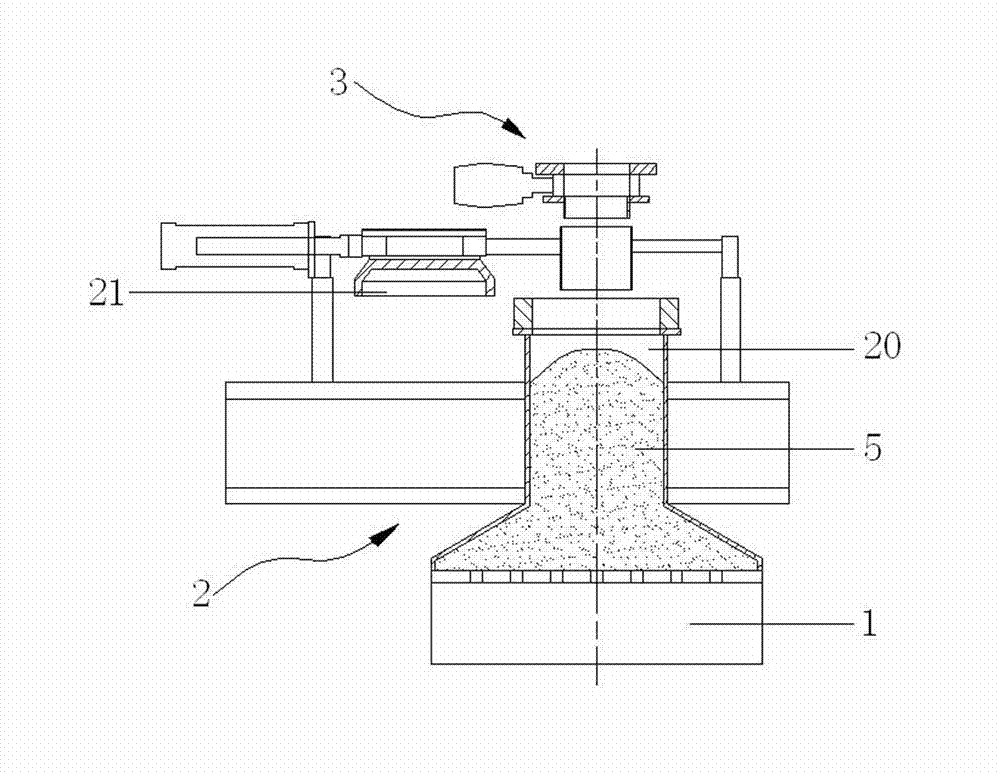

[0014] Such as figure 1 , 2 The shown cold box core shooting device includes a core box 1 with a sand core cavity, a sand shooting mechanism 2 arranged on the upper part of the core box 1 , and a sand adding mechanism 3 .

[0015] Wherein: the sand-shooting mechanism 2 includes: the shot chamber 20 whose lower part communicates with the core box 1, the movable intake valve cover 21 which is arranged on the upper part of the shot cavity 20 and can move in the horizontal direction, and the movable intake valve cover 21 which communicates with the movable intake valve cover 21. The blowing mechanism (not shown in the figure); the sand adding mechanism 3 includes a sand adding bucket 30 arranged directly above the injection chamber 20, and a butterfly valve 31 arranged at the lower part of the sand adding bucket 30 for controlling its opening and closing. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com