Double-rocker arm type independent suspension system

An independent suspension, double rocker arm technology, applied in suspension, elastic suspension, cantilever mounted on the pivot and other directions, can solve the problems of complex installation, increased assembly difficulty, inconvenient installation, etc., to achieve comfortable ride, reduce The effect of assembly technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

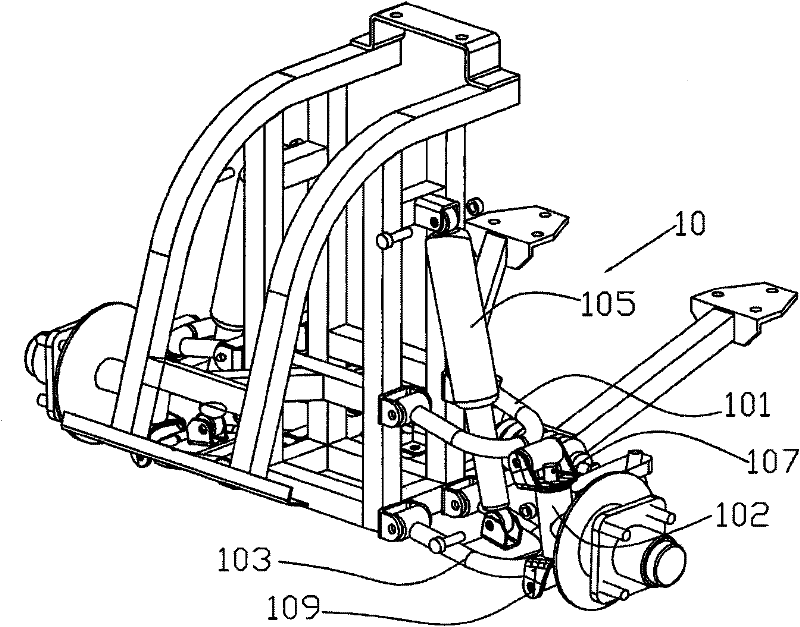

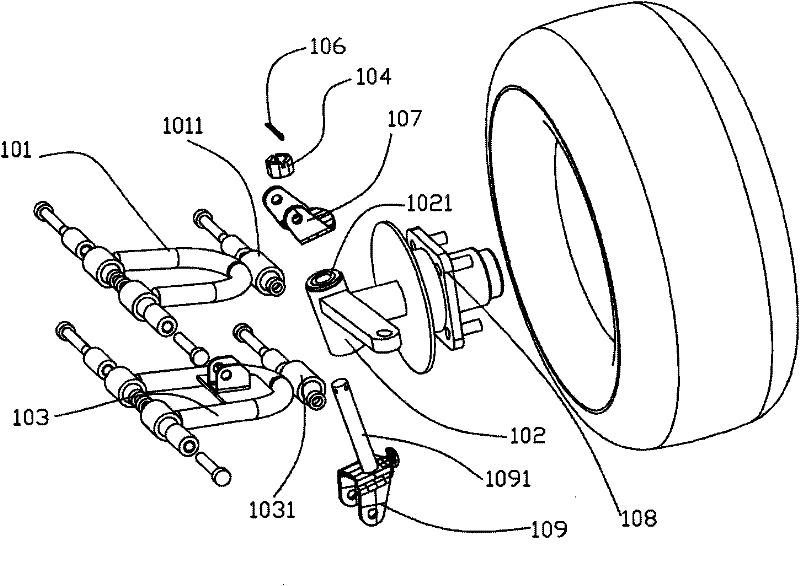

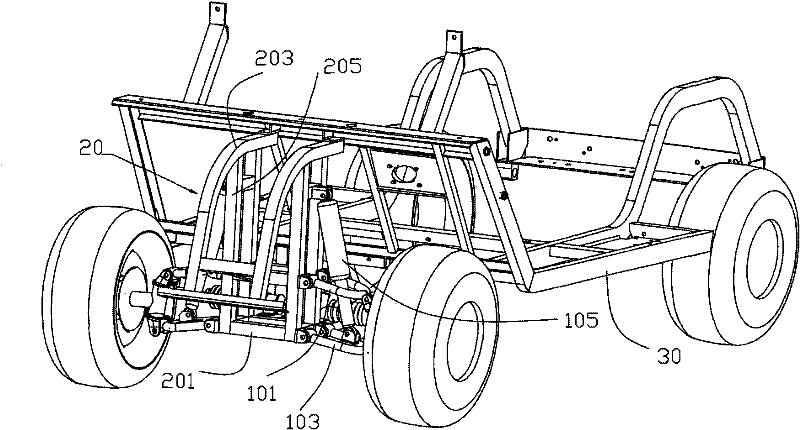

[0023] Such as figure 1 As shown, the double rocker arm type independent suspension device 10 of the present invention comprises an upper rocker arm 101, a lower rocker arm 103 and a shock absorber 105 symmetrically arranged on both sides of the vehicle body. 107 is oscillatingly connected, and the lower swing arm 103 is oscillatingly connected with the first rotating device 109 near the end of the wheel, and the first rotating devices 107 and 109 are rotatably connected with the second rotating device 102 . Preferably, the lower rocker arm 103 is longer than the upper rocker arm 101 , and the upper rocker arm 101 and the lower rocker arm 103 are parallel and U-shaped.

[0024] It should be noted that the upper rocker arm 101 and the lower rocker arm 103 can be installed on the front wheels of the car through the first rotating devices 107 and 109 respectively. In the best embodiment of the present invention, the upper rocker arm 101 and the The lower rocker arm 103 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com