Optical lens structure

A technology of lens structure and curved surface, applied in lighting devices, lighting device parts, refractors, etc., can solve the problem that flood lighting equipment cannot be directly applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

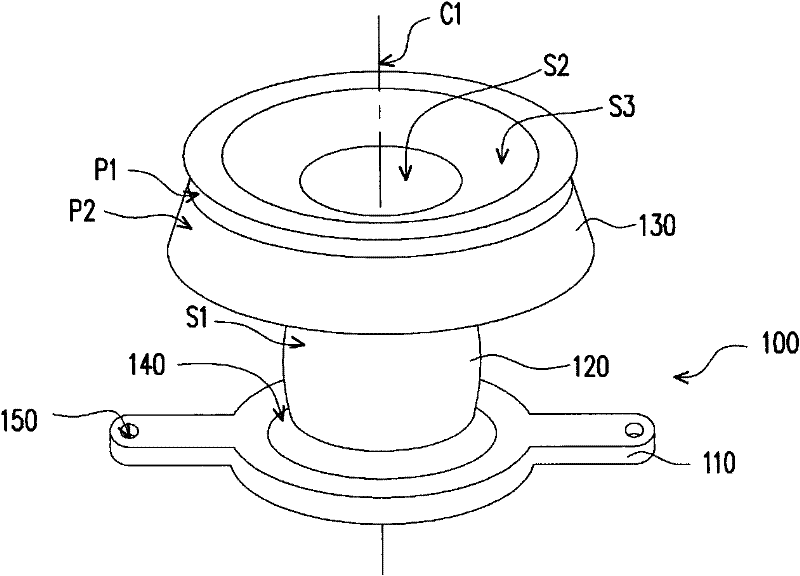

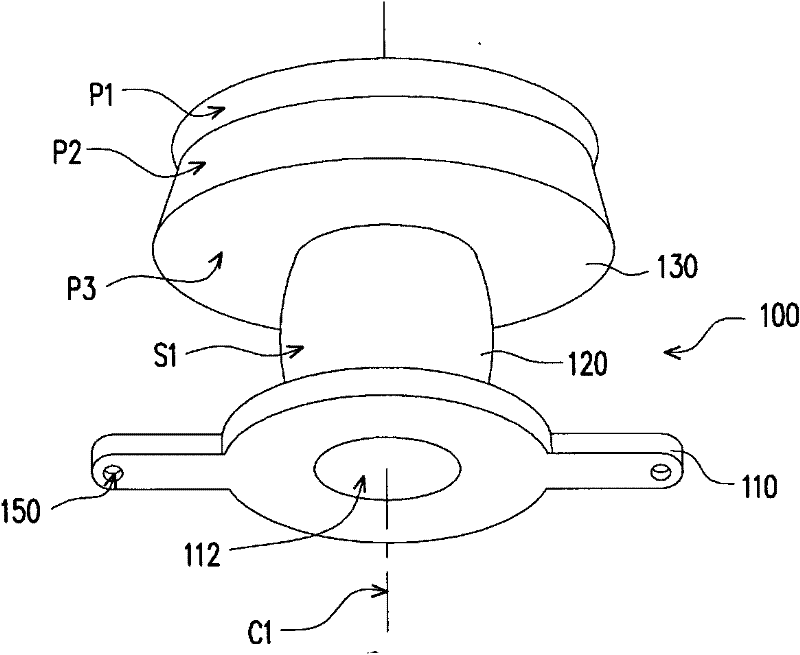

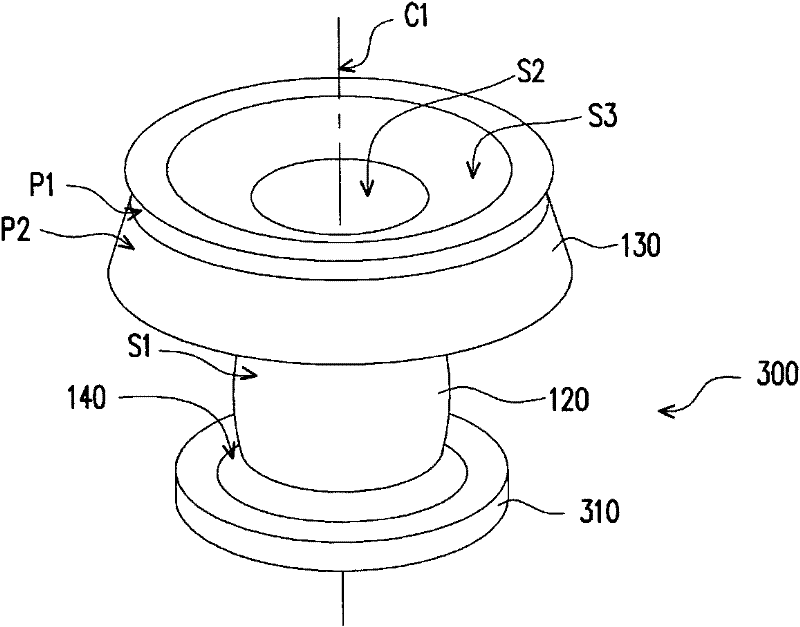

[0036] Figure 1A and Figure 1B It is a perspective view of a lens structure in different viewing angles according to an embodiment of the present invention. Figure 2A and Figure 2B It is a perspective view of a lens structure of another embodiment of the present invention at different viewing angles. image 3 for Figure 1A Side view of the lens structure. Please also refer to Figure 1A to Figure 3 , the lens structure 100 is suitable for directing the light emitted by a light source 200 into multiple directions. In this embodiment, the lens structure 100 includes a base 110 , a cylinder 120 and an umbrella 130 . The base 110 has a receiving groove 112 suitable for receiving the light source 200 . In this embodiment, the light source 200 is, for example, a light emitting diode, which is not limited in this embodiment, and any directional light source is applicable to this embodiment.

[0037] The cylinder 120 is connected to the base 110 . The cylinder 120 has a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com