Method for manufacturing ultrasonic sensor, ultrasonic sensor, and banknote handling apparatus comprising ultrasonic sensor

A technology of ultrasonic sensor and transmission direction, which is applied in the direction of sensor, sensor type, piezoelectric/electrostrictive device manufacturing/assembly, etc., which can solve the problems of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

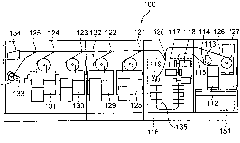

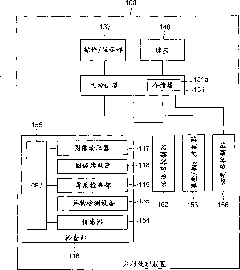

[0029] Referring to the accompanying drawings, a method for manufacturing an ultrasonic sensor, an ultrasonic sensor, and a banknote processing device including the ultrasonic sensor according to embodiments of the present invention will be described in detail below.

[0030] figure 1 It is a perspective view showing the appearance of a sheet processing apparatus (banknote processing apparatus) 100 according to one embodiment. Such as figure 1 As shown, the sheet processing apparatus 100 includes an insertion port 112 , an operation portion 136 , an operation / display portion 137 , a door 138 , a removal port 139 , and a keyboard 140 located outside the apparatus.

[0031] The insertion port 112 is configured to be capable of inserting a sheet 7 such as a banknote therein. The insertion port 112 receives a batch of stacked sheets 7 . The operation unit 136 receives various operation inputs from the operator. The operation / display unit 137 displays various operation guidance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com