Ferromagnetic pipeline tiny defect magnetic detection sensor

A sensor and magnetic detection technology, which is applied in the direction of material magnetic variables, can solve the problems of small permanent magnets to reduce the magnetization magnetic field strength, reduce the amount of information of the detection sensor, and low detection accuracy, so as to optimize the magnetization effect, strengthen the detection effect and sensitivity, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it. For convenience of description, the present invention will be described below by taking an oil stealing hole as an example. It should be understood that the present invention can also be applied to defect detection of non-pipe ferromagnetic materials.

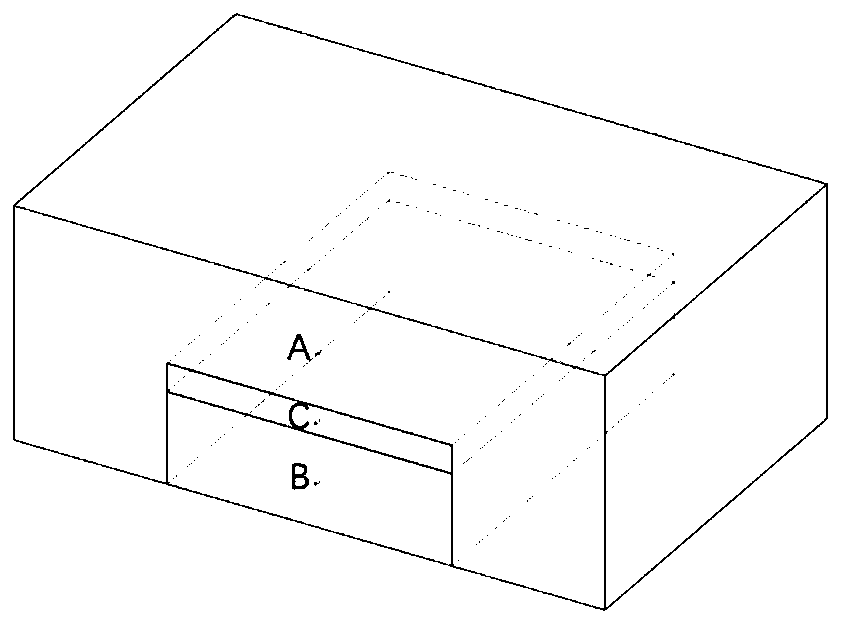

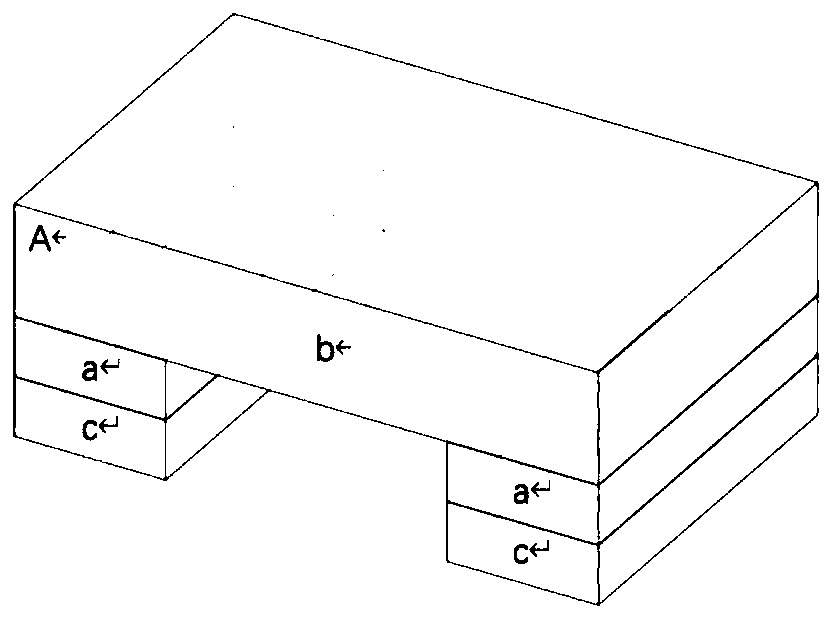

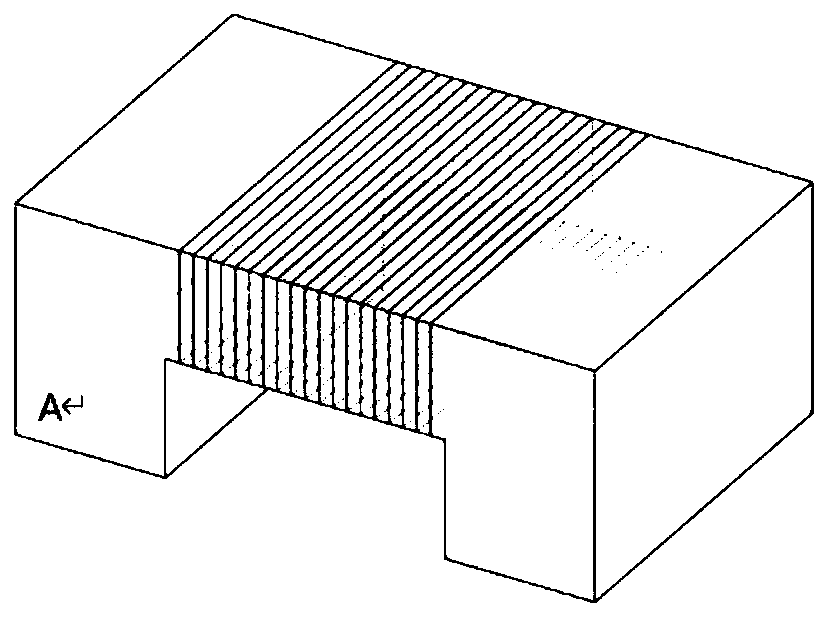

[0030] Such as figure 1 As shown, the ferromagnetic pipeline micro-defect magnetic detection sensor of the present invention is in the shape of a cuboid as a whole and its lower surface is in an arc consistent with the curvature of the pipeline wall, so as to better approach or even fit the pipeline wall during the detection process. It should be understood that it can The invention detects the radian of the lower surface of the sensor according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com