Connector and connector matching method

A connector and mating state technology, which is applied in the direction of connection, parts of the connecting device, coupling device, etc., can solve the problems of damaging the reliability of the connector mating, dust sticking to the mating surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

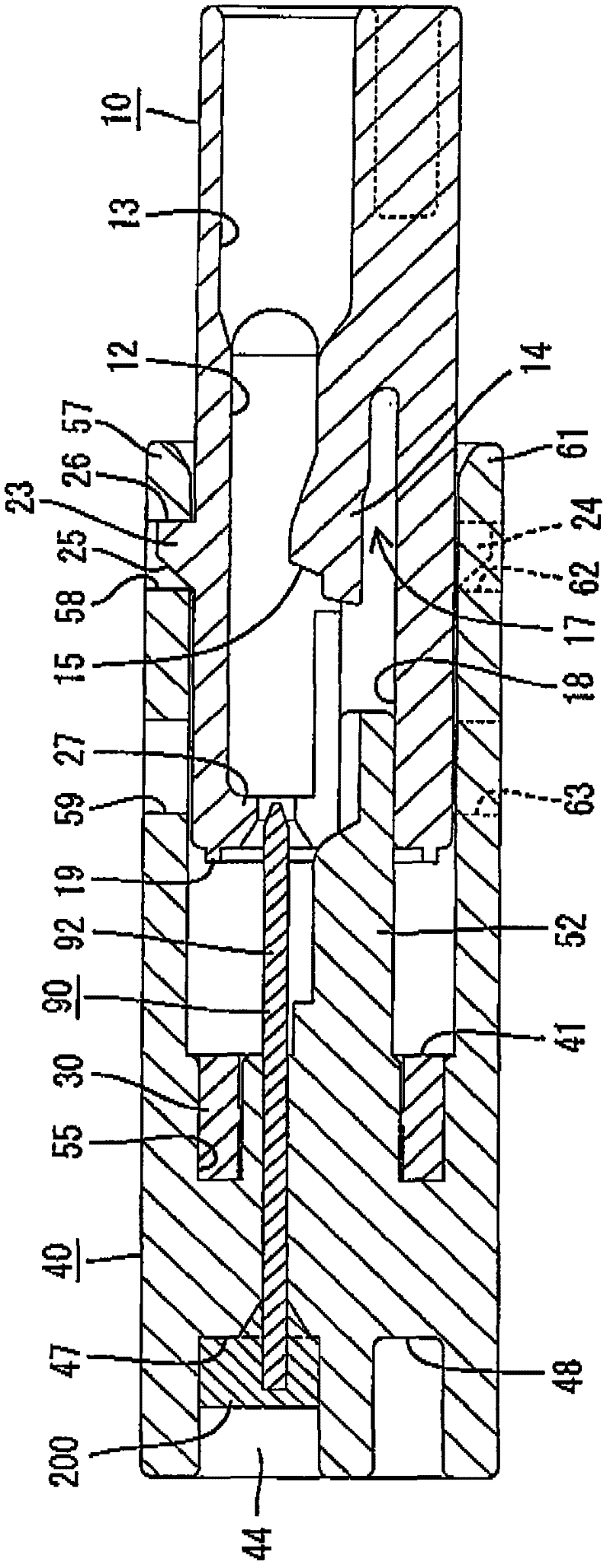

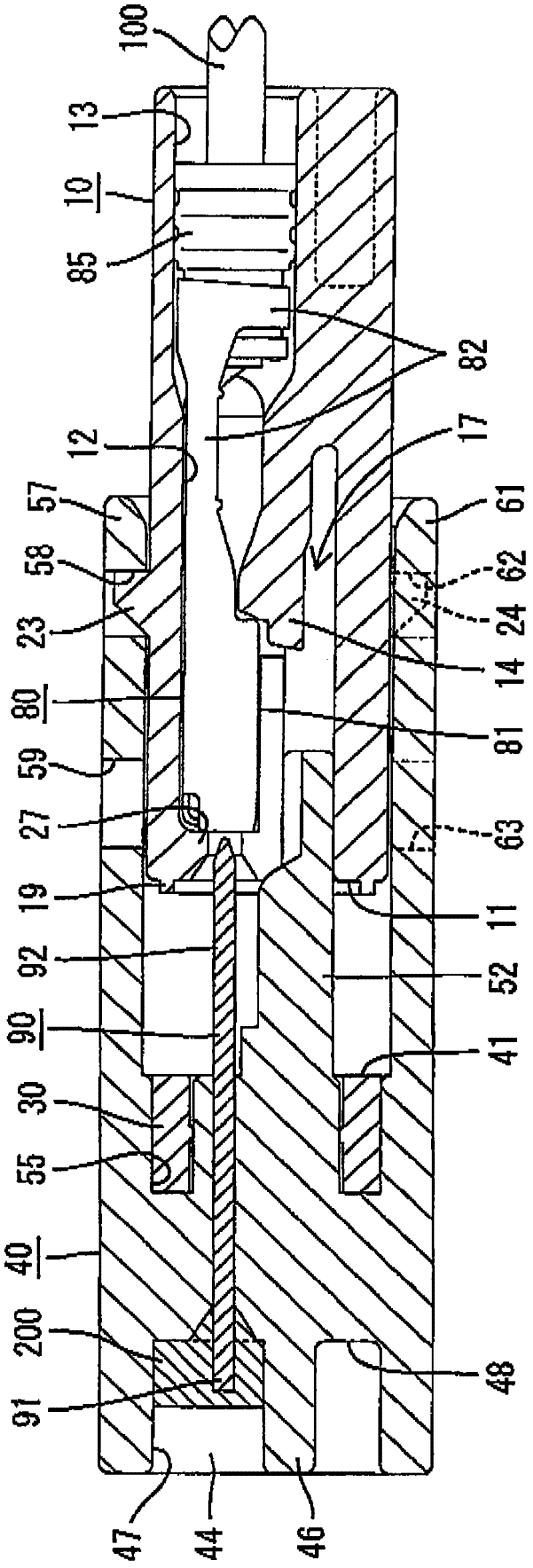

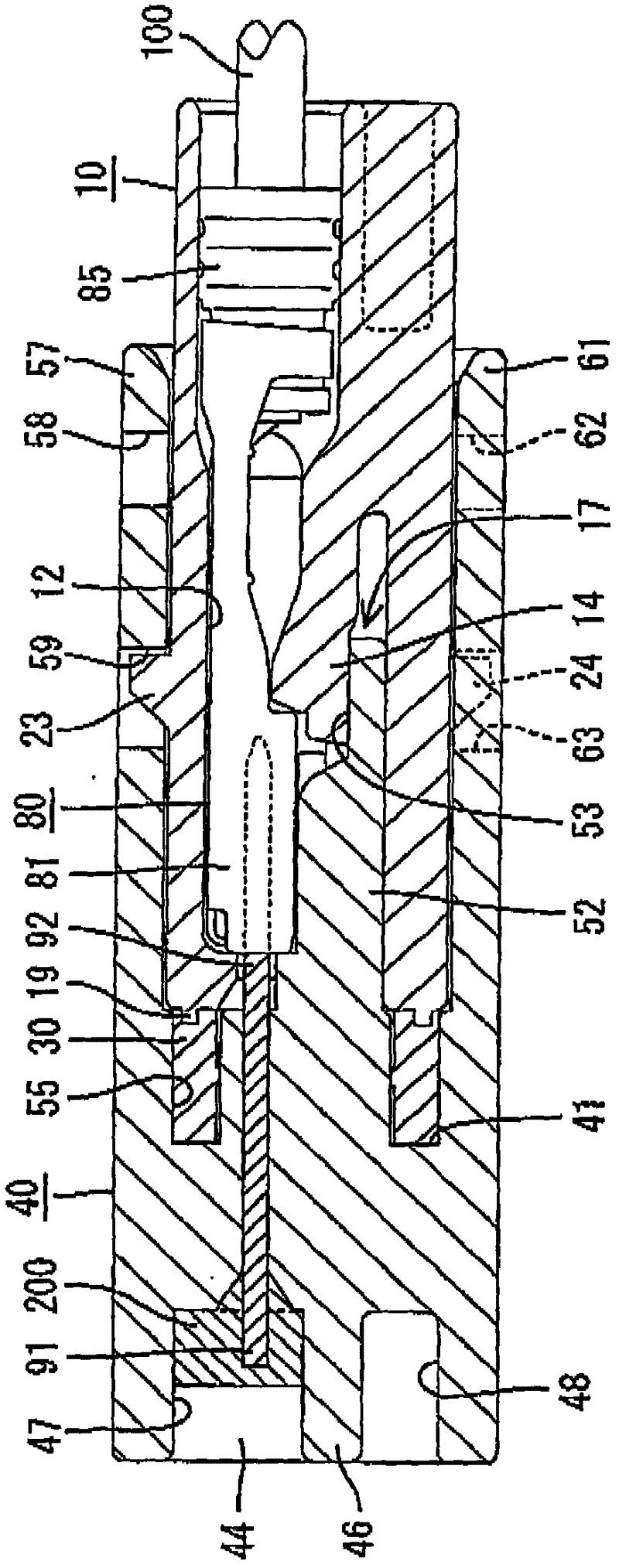

[0059] In the following, reference will be made to Figure 1 to Figure 9 Example 1 of the present invention will be described. The connector according to Embodiment 1 is equipped with a first housing 10 and a second housing 40 capable of fitting with each other. The first terminal fitting 80 and the second terminal fitting 90 are fitted to the first housing 10 and the second housing 40, respectively. The second terminal fitting 90 is configured as a fitting terminal not connected to an electric wire. In the following description, the respective mating surface sides (opposing surfaces 11 , 41 ) of the first housing 10 and the second housing 40 are set to the front side in the longitudinal direction.

[0060] The first housing 10 is formed of synthetic resin, and has a flat block shape, such as figure 1 with Figure 8 shown. A plurality of cavities 12 are formed in the first housing 10 to be aligned in the width direction. Rubber plug insertion ports 13 , into which rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com