Magnetocaloric thermal generator

A technology of heat generators and magnetocaloric elements, applied in thermoelectric devices utilizing thermal changes in magnetic permeability, machines using electric/magnetic effects, energy-saving heating/cooling, etc., can solve problems such as speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the illustrated embodiments, the same parts or parts bear the same reference numerals.

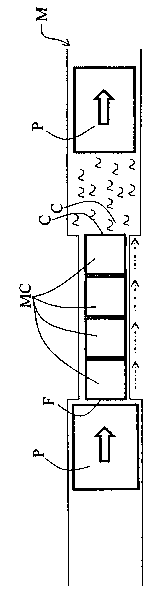

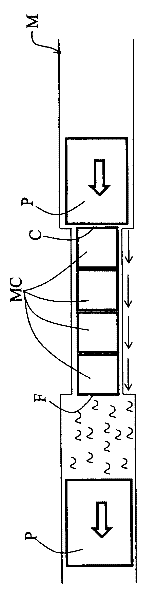

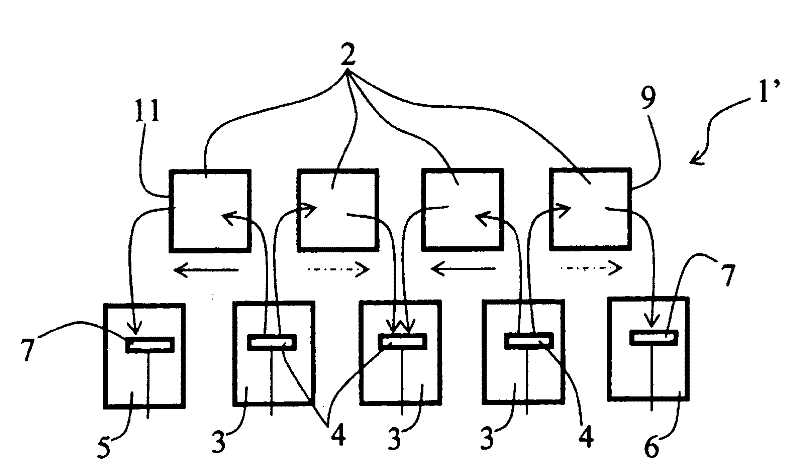

[0032] exist image 3 with Figure 4 The heat generator 1 shown in is realized according to the first embodiment of the invention. It comprises two thermal modules 1' each comprising some magnetocaloric elements 2 arranged in a line. The common chamber 3 , comprising a piston 4 forming a forced flow of heat-carrying fluid, is located each time between two adjacent magneto-caloric elements 2 . In addition, said thermal module 1' also comprises two end chambers 5 and 6 located at the hot end 9 and the cold end 11 of said thermal module 1' and each also comprising a piston forming a flow-through part 7.

[0033] Each magneto-caloric element 2 is adapted to flow through a heat transfer fluid driven by pistons 4, 7 and is subjected to magnetic field variations by means of magnetic means (not shown) that produce alternating heating and cooling cycles. The movement of the pistons 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com