Secondary battery and manufacturing method therefor

A technology for secondary batteries and battery casings, which is applied in secondary battery manufacturing, secondary batteries, lithium batteries, etc., can solve the problems of high battery assembly costs and high battery manufacturing costs, achieve compactness inside the battery casing, and reduce internal resistance. , the effect of shortening the current path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

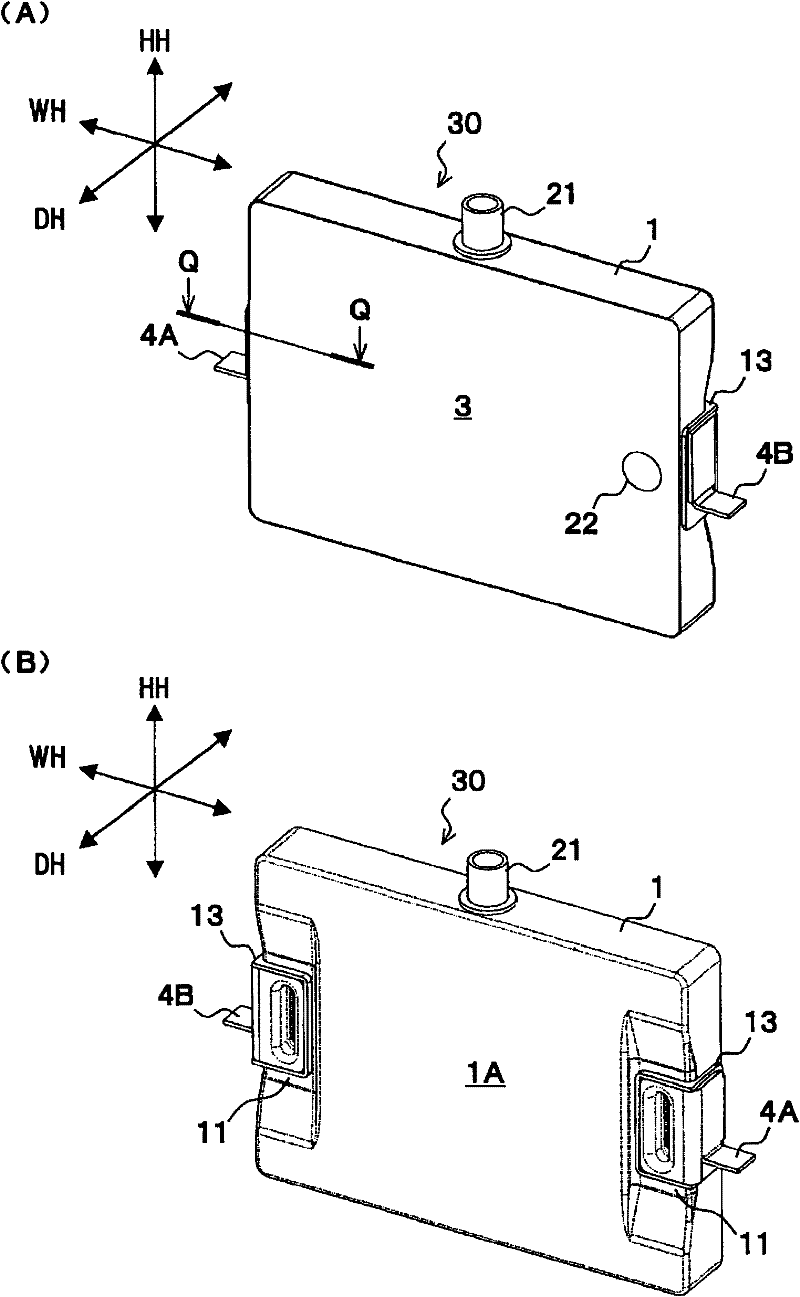

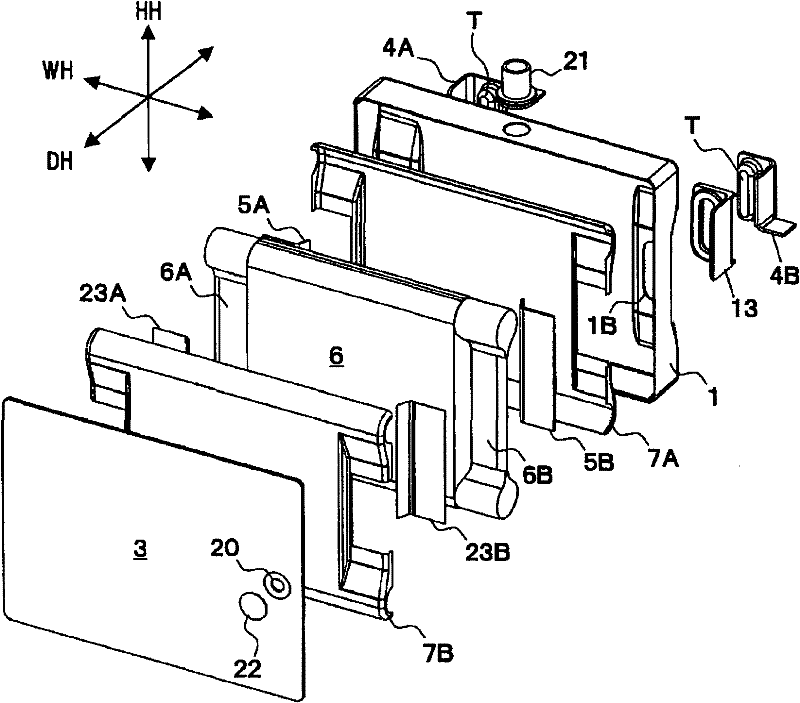

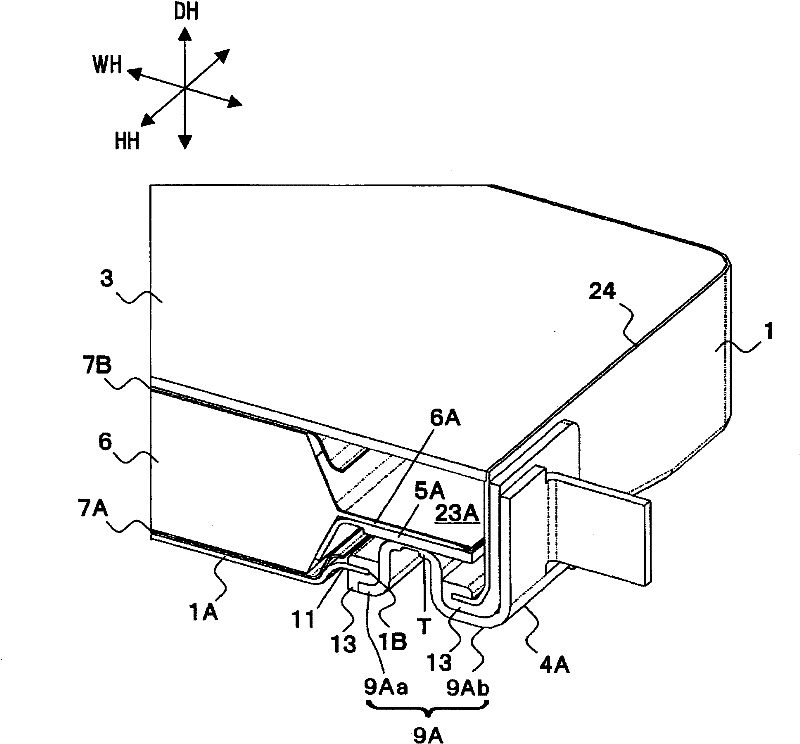

[0031] Hereinafter, an embodiment of a lithium ion secondary battery to which the present invention is applied will be described with reference to the drawings.

[0032] Such as figure 1 As shown in (A), the lithium ion secondary battery 30 according to the embodiment of the present invention includes a battery case 1 having an opening portion open on the entire surface; and a battery cover 3 that seals the opening portion of the battery case 1. In the space defined by the battery case 1 and the battery cover 3, the power generating element group formed by winding the positive and negative plates is arranged so as to be immersed in the electrolyte.

[0033] Regarding the battery case 1, the length of the other side orthogonal to the two sides is formed to be shorter than the length of any one of the four sides constituting the outer periphery of the opening. That is, the battery case 1 is formed in a shallow, bottomed rectangular parallelepiped shape in which the length of one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com