Spinning punch forming method for refrigerator door panel

A stamping forming and door panel technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

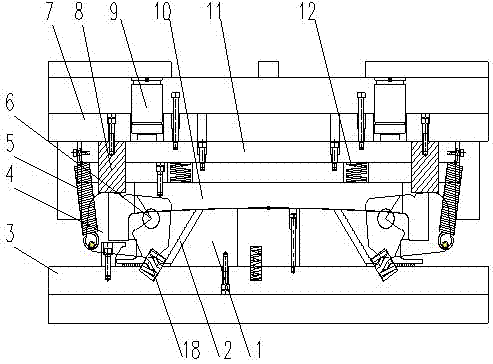

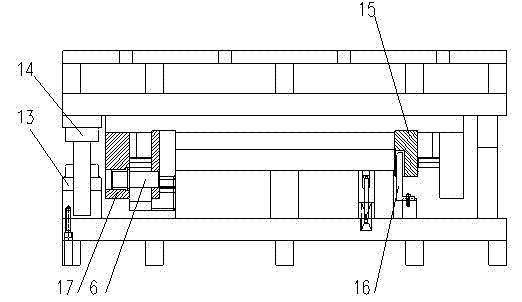

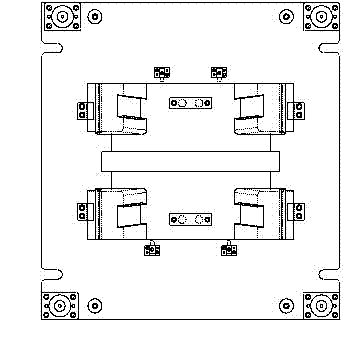

[0034] Such as Figure 7 and 8 As shown, the working principle of the present invention is as follows: first, the mold is installed on the punch press, and the upper and lower mold mechanisms are opened; the workpiece is put in, the upper slide block of the punch press goes down, the rectangular spring 12 is compressed, and the first-stage floating binder plate 10 is pressed The workpiece is retracted gradually, and the bending die 4 and the front and rear dies 15 enter the forming punch 2 to start bending the B2 side, which is the first stage. At this stage, two conditions must be met: ①The swivel bending die 4 cannot be rotated; Figure 8 The state shown, otherwise the appearance requirements of the workpiece after forming and the completion of other movements cannot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com