Iron powder tin-based composite soldering alloy ball and flip chip bumping method thereof

A technology of alloy ball and ball planting, which is applied in the direction of welding medium, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the examples. It should be understood that these examples are only for the purpose of illustration, and in no way limit the protection scope of the present invention.

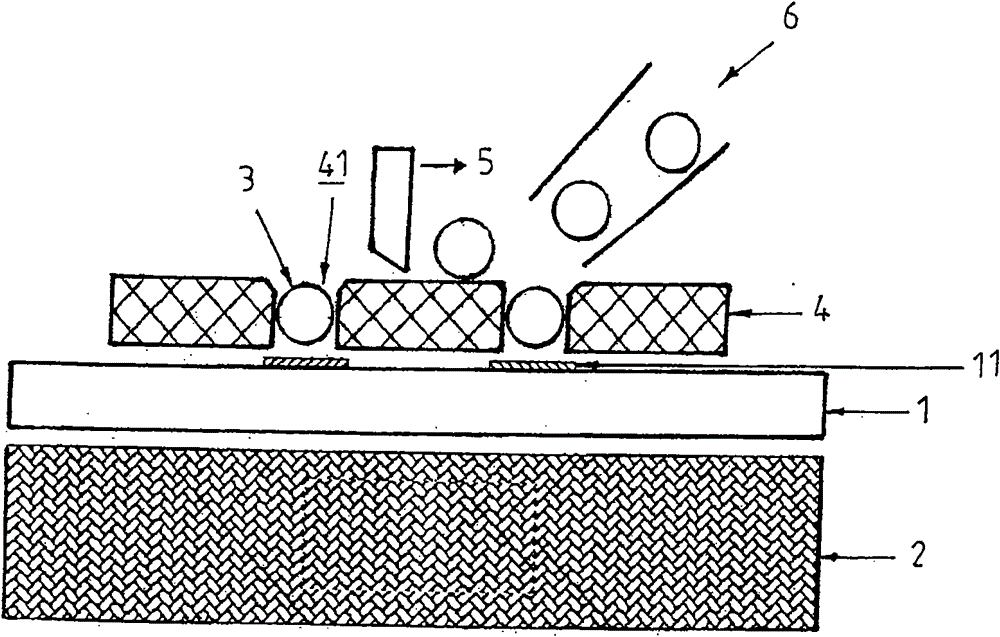

[0010] The present invention mainly includes two stages of technical features, one is to mix iron powder into solder alloy balls to form a combined structure of composite solder alloy balls to improve the bonding strength between circuit boards and electronic components; It is used in flip-chip ball planting technology, and it also has the effect of simplifying the process.

[0011] Regarding the manufacturing method of iron powder tin-based composite solder alloy balls, since the solubility and diffusion ability of iron in solder are extremely low, there is no concern about coarsening. According to literature, the addition of iron can effectively improve the normal temperature tensile strength of solder Strength, especially in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com