Temperature testing device

A technology for testing devices and temperature sensors, which is applied in measuring devices, radiation pyrometry, optical radiation measurement, etc., can solve the problems of heavy workload, poor contact, complicated connection, etc., to improve work efficiency, fast and efficient Sensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

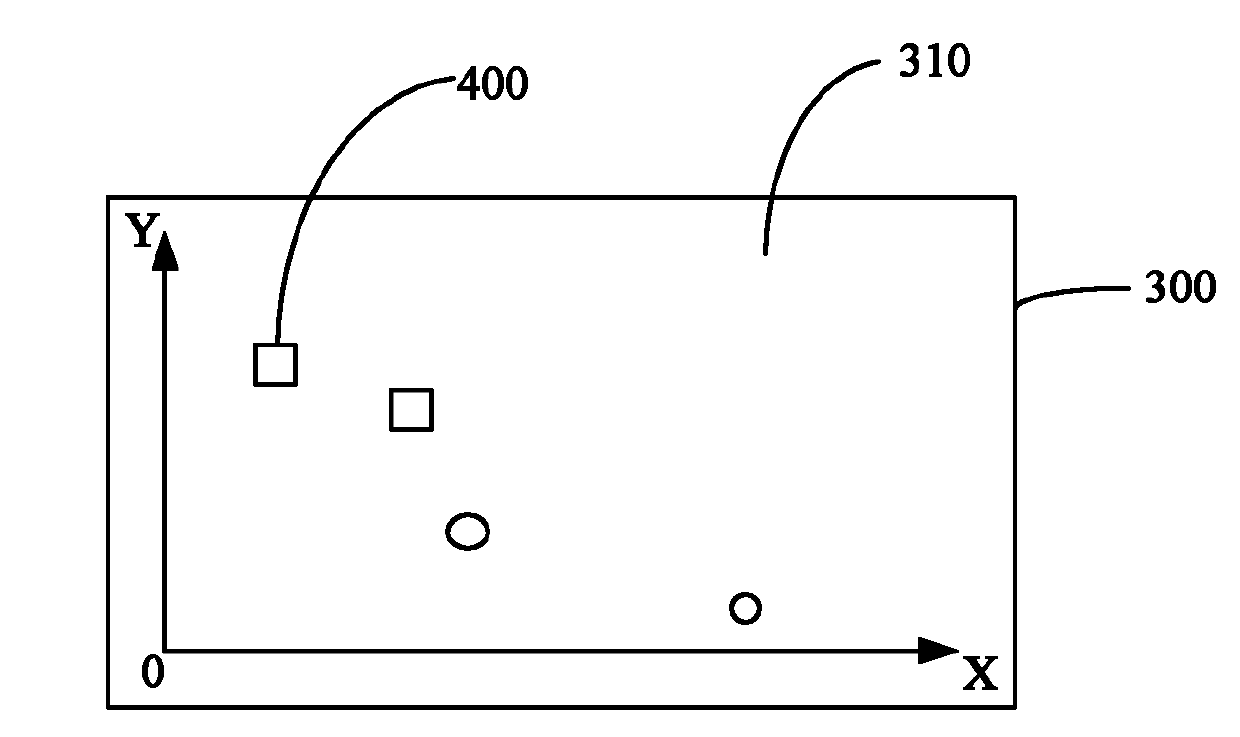

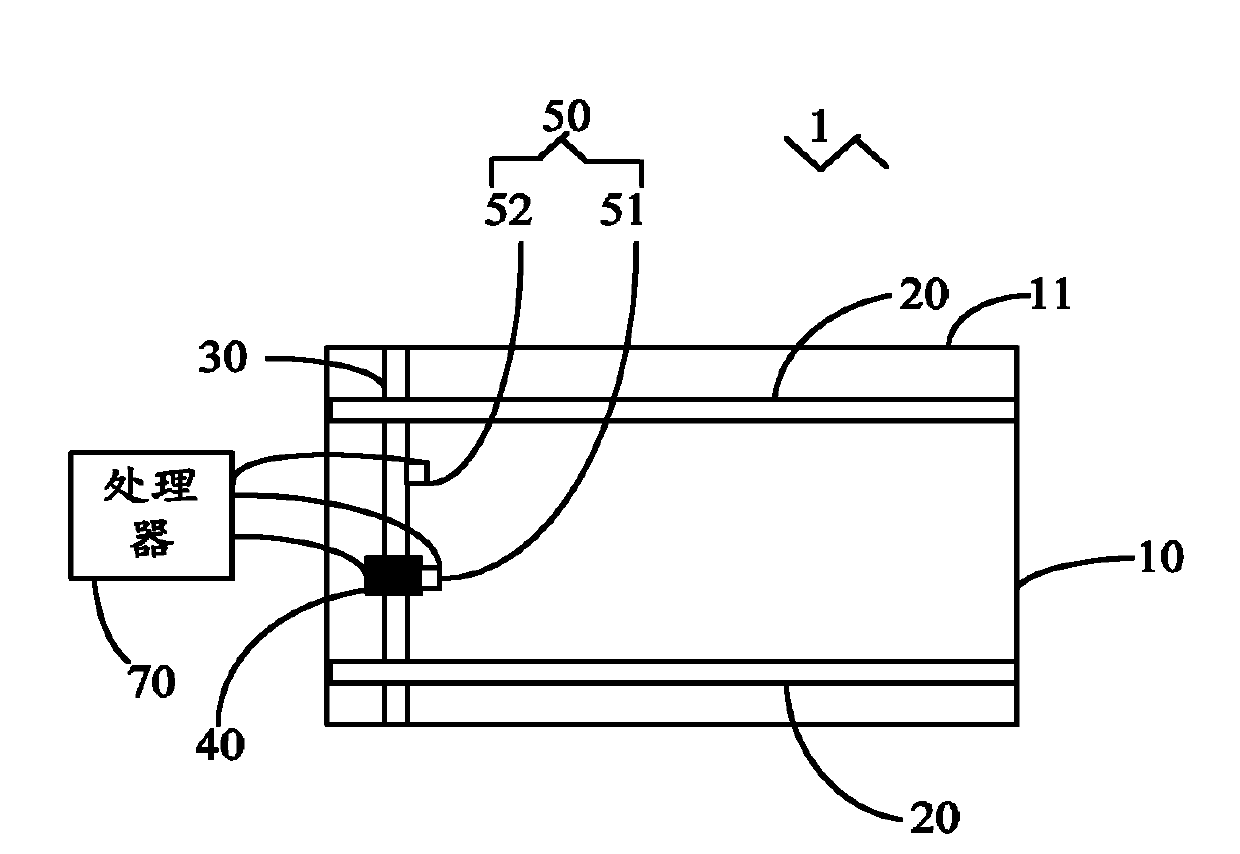

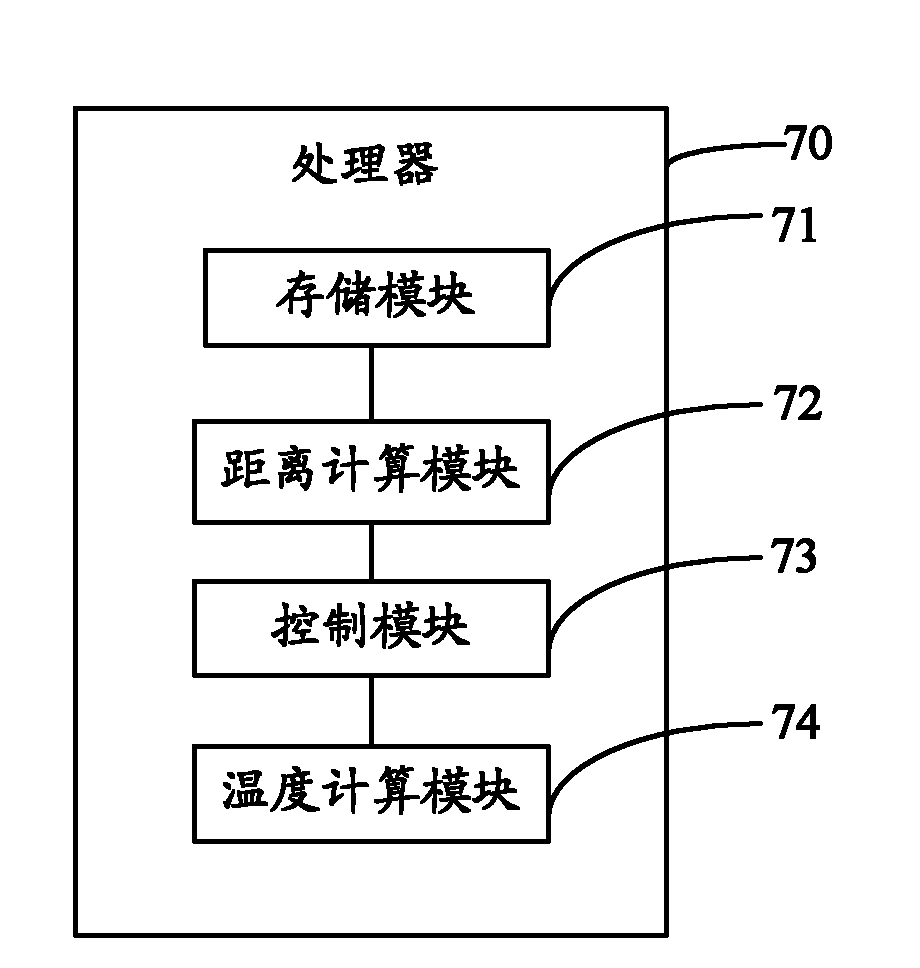

[0028] see figure 1 and figure 2 , is a temperature testing device 1 provided in an embodiment of the present invention, which is used to test the temperature of multiple electronic components 400 fixed on the same circuit board 300 . The temperature testing device 1 includes a fixed frame 10 , two guide rails 20 , a sliding rail 30 , a temperature sensor 40 , a driving device 50 and a processor 70 .

[0029] The circuit board 300 is substantially rectangular, and includes a connection surface 310 , and the plurality of electronic components 400 are all fixed on the connection surface 310 .

[0030] The fixed frame 10 is a rectangular frame including four frame sides 11 . The fixing frame 10 is disposed on one side of the connection surface 310 for fixing the circuit board 300 .

[0031] The two guide rails 20 are arranged in parallel on two opposite fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com