Total effect toothpaste and preparation method thereof

The technology of toothpaste and strontium hydroxyapatite is applied in the field of full-effect toothpaste and its preparation, which can solve problems such as single efficacy and achieve the effects of comprehensive efficacy and good oral health care effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

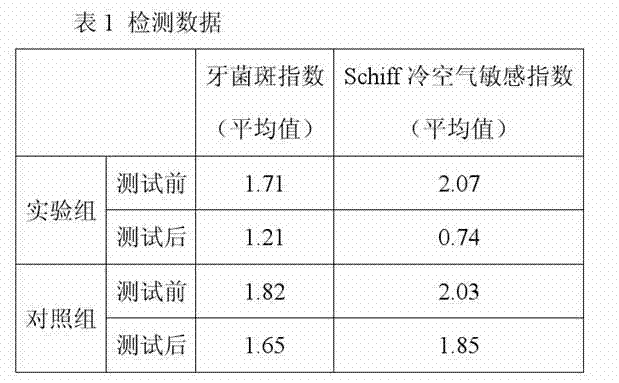

Image

Examples

Embodiment 1

[0032] Step 1: Stir the humectant (sorbitol 20kg+glycerin 8kg), adhesive (hydroxymethylcellulose sodium 0.8kg) and 0.1kg chitosan evenly to obtain jelly;

[0033] Step 2: Add the jelly obtained in step 1, sweetener (0.15 kg of acesulfame potassium) and 0.05 kg of vitamin A to 18 kg of deionized water and mix evenly to prepare glue;

[0034] Step 3: Inhale the glue obtained in step 2 into the toothpaste making machine, and at the same time add friction agent (calcium hydrogen phosphate 20kg + calcium carbonate 20kg), strontium-doped 10% hydroxyapatite 2kg, β-phosphoric acid into the toothpaste making machine Tricalcium 8kg, Rhizoma Drynariae 0.5kg, Radix Astragali 0.1kg, spices (0.8kg essence) and foaming agent (sodium lauryl sulfate 1.5kg), stir and mix evenly, and vacuum desorb at least under a negative pressure of 0.096pa. Gas for 45 minutes, and the finished product can be obtained after filling.

Embodiment 2

[0036] Step 1: Stir and mix humectant (sorbitol 10kg+polyethylene glycol 5kg), adhesive (xanthan gum 1.3kg) and 0.15kg chitosan evenly to obtain jelly;

[0037] Step 2: Add the jelly, sweetener (0.2kg of saccharin) and 0.15kg of vitamin A obtained in step 1 into 28kg of deionized water and mix evenly to make glue;

[0038] Step 3: Inhale the glue obtained in step 2 into the toothpaste making machine, and at the same time add friction agent (37 kg of calcium hydrogen phosphate), 2.5 kg of hydroxyapatite doped with 6% strontium, and β-tricalcium phosphate into the toothpaste making machine 12kg, drynaria 0.7kg, astragalus 0.3kg, spices (essence 1kg) and foaming agent (sodium lauryl sulfate 1.7kg), stir and mix evenly, and vacuum degas at least 60 minutes under a negative pressure of 0.096pa , the finished product is obtained after filling.

Embodiment 3

[0040] Step 1: Stir and mix humectant (sorbitol 18kg+polyethylene glycol 2.5kg), adhesive (hydroxymethylcellulose sodium 1kg+carrageenan 0.5) and 0.3kg chitosan to obtain a jelly;

[0041] Step 2: Add the jelly, sweetener (0.2kg sodium saccharin + 0.1kg saccharin) and 0.2kg vitamin A obtained in step 1 into 30kg deionized water and mix evenly to make glue;

[0042] Step 3: Inhale the glue obtained in step 2 into the toothpaste making machine, and at the same time add friction agent (calcium hydrogen phosphate 20kg), 6kg of hydroxyapatite doped with 8% strontium, and 16kg of β-tricalcium phosphate into the toothpaste making machine , Rhizoma Drynariae 1kg, Radix Astragali 0.5kg, Spices (Flavor 1.2kg) and Foaming Agent (Sodium Lauryl Sulfate 1.5kg+ Sodium Lauroyl Sarcosinate 1kg), stir and mix evenly, in the environment of negative pressure 0.096pa Vacuum degassing for 50 minutes, and the finished product is obtained after filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com