Device for measuring layer thickness of print ink on ink roller

A technology for printing ink and layer thickness, applied in the field of layer thickness devices, can solve the problem that the function will be adversely affected by dirt and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

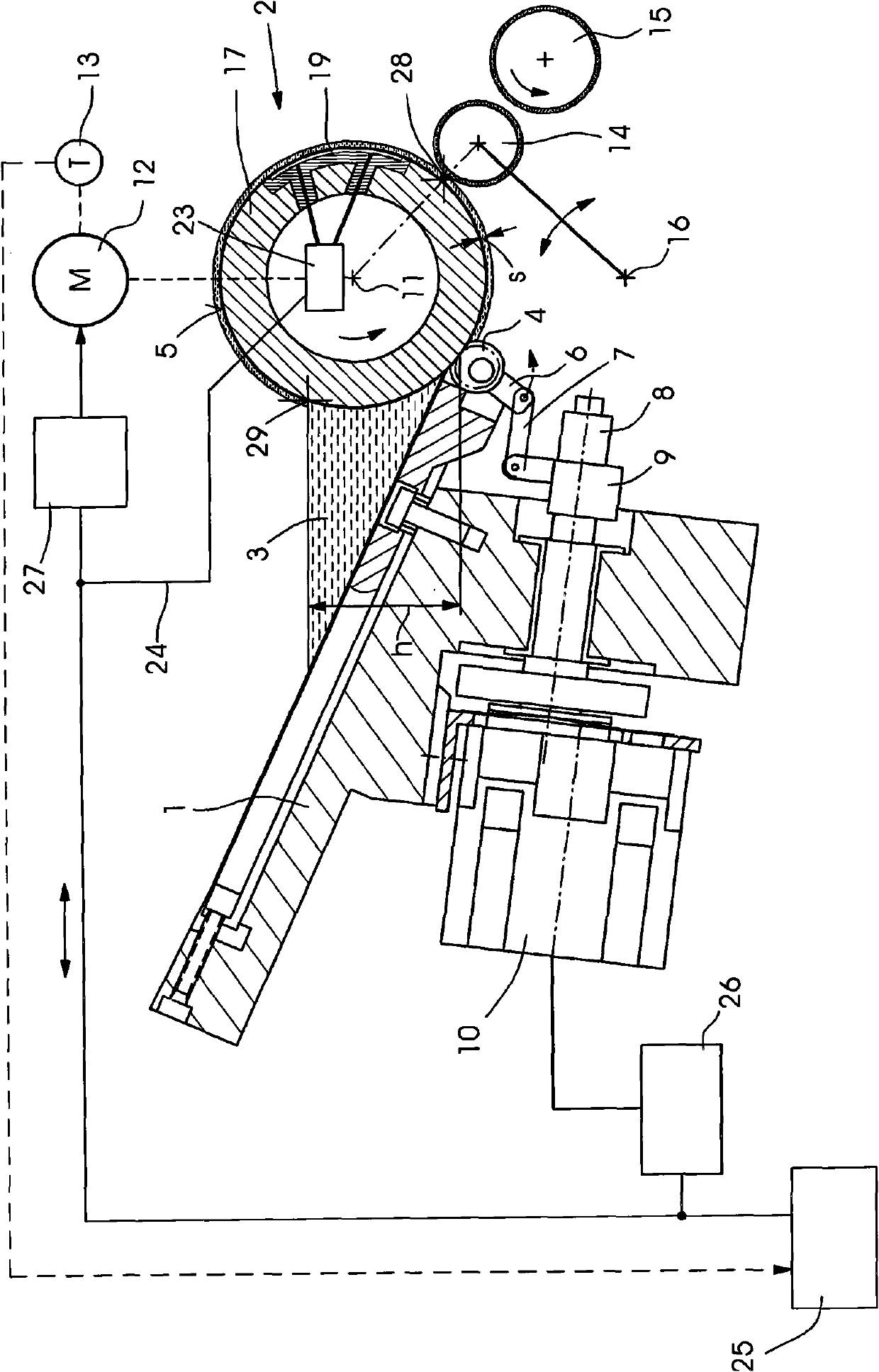

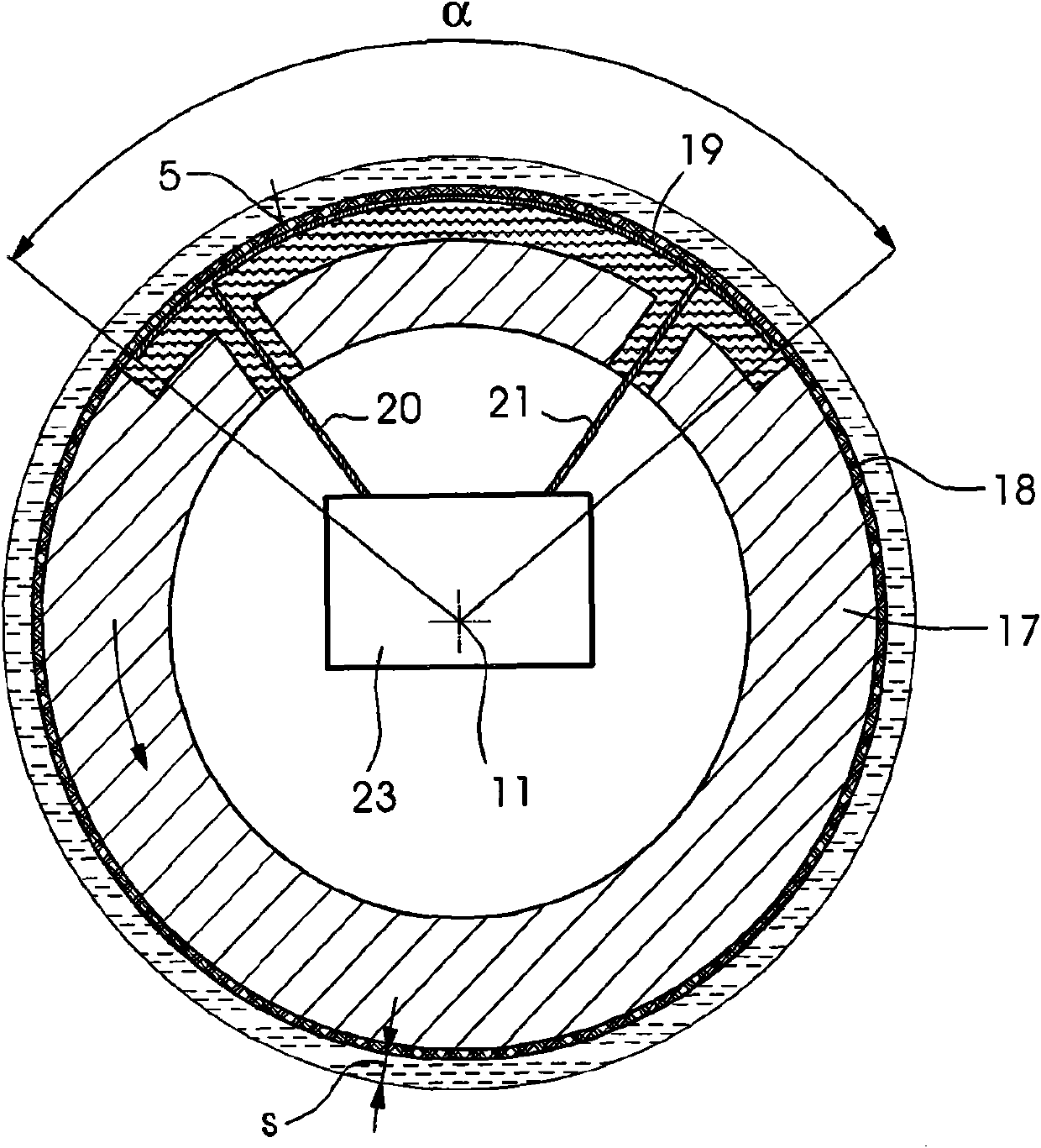

[0017] figure 1 An ink fountain 1 is shown, into which an ink fountain roller 2 is immersed. In the ink fountain 1 there is printing ink 3 at a liquid level h. On the underside of the ink fountain 1 there is a metering element 4 whose distance from the outer surface 5 of the ink fountain roller 2 can be adjusted by means of the transmission elements 6 to 9 and the servomotor 10 in such a way that a An ink film with the desired layer thickness s. In the direction of the axis of rotation 11 of the ink fountain roller 2 , the metering elements 4 and their adjusting elements are present in multiples, so that the layer thickness s can be adjusted in several regions. For driving the ink fountain roller 2, a motor 12 and an automatic synchronization transmitter 13 are provided. Printing ink is transferred from said outer surface 5 to an ink transfer roller 15 by means of an ink transfer roller 14 . The ink transfer roller 14 can swing back and forth around an axis 16 .

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com