Quick installation lock of LED mould

A technology of LED modules and lock boxes, applied in building locks, identification devices, instruments, etc., can solve the troublesome and time-consuming installation and removal of LED modules, inability to install and remove LED modules, and module installation and maintenance personnel. Inconvenience and other problems, to achieve the effect of reducing installation screw consumables, simple structure, and reducing installation work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

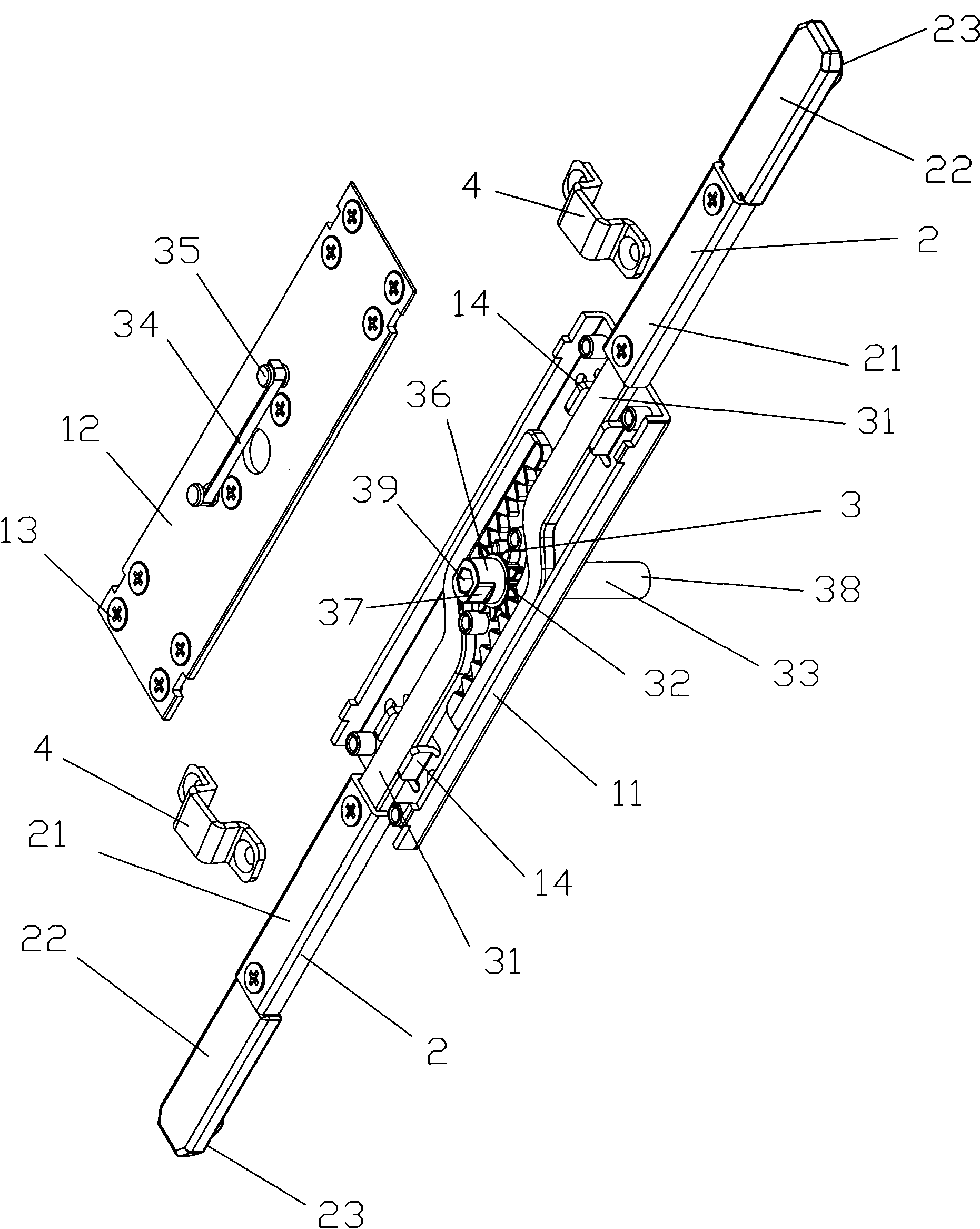

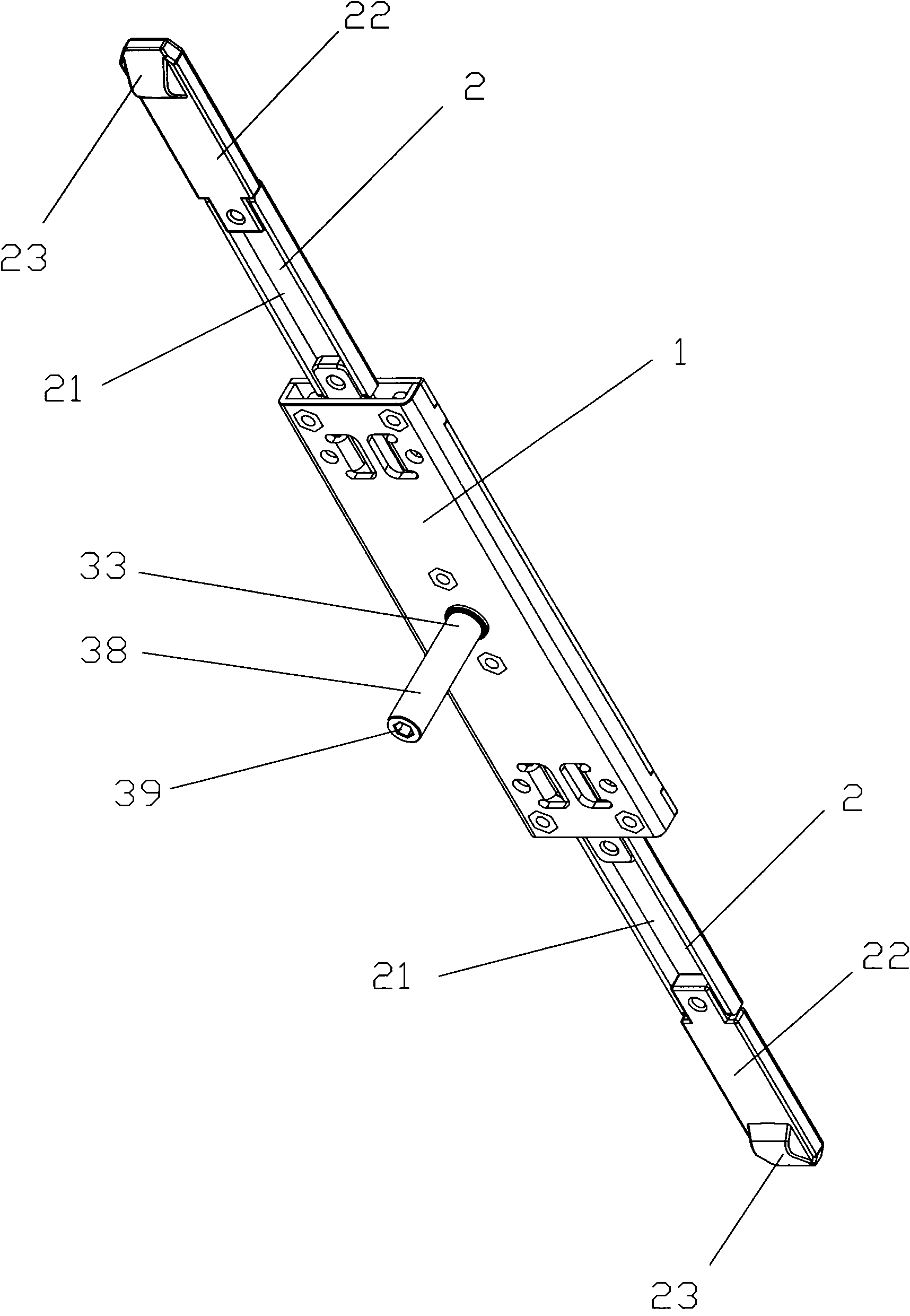

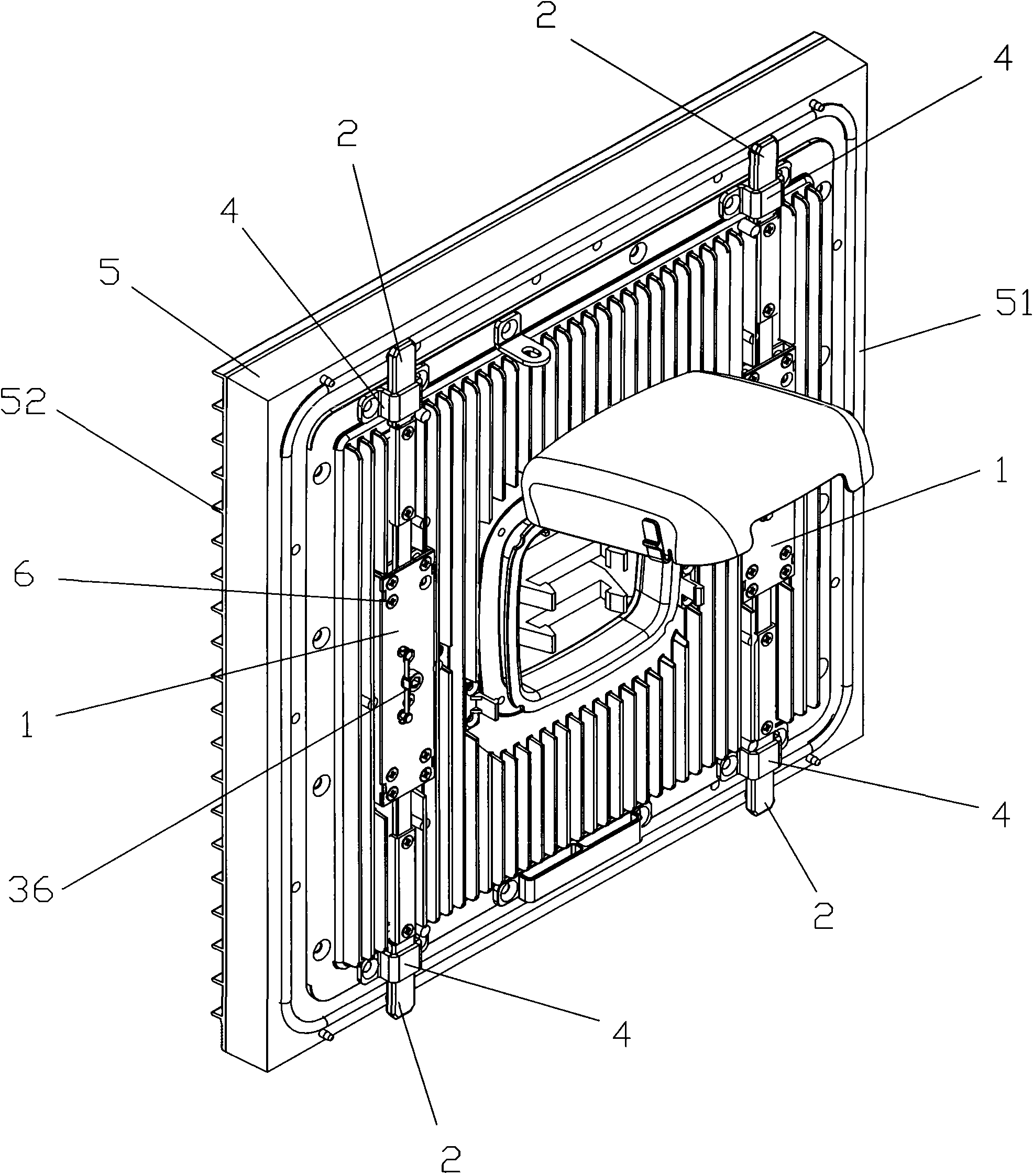

[0028] From figure 1 with figure 2 It can be clearly seen that the LED module quick-installation lock includes a lock box body 1 with lock tongues extending out of the window holes at both ends. The lock box body 1 is equipped with a lock that can promote the simultaneous linear telescopic movement of the lock tongue 2 at both ends. The locking mechanism 3 and the elongated bolt 2 are provided with a lock catch 4 matched with it.

[0029] The lock box body 1 is assembled from a face box 11 and a back cover 12 through screws 13. The lock box body 1 is provided with a limit slot 14 which can ensure the parallel and linear movement of the two racks 31 of the lock mechanism 3.

[0030] The locking mechanism 3 is composed of two racks 31 arranged in parallel on the inner tooth surface of the lock box body 1 opposite to each other, a gear 32 arranged between the two racks 31 and capable of being engaged with the gear 32, and a shaft 33 through which the steering gear 32 rotates. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com