Winding device

A transmission device and retaining device technology, applied in the transmission device, friction transmission device, transportation and packaging, etc., can solve the problems of cumbersome, cores that cannot maintain a constant distance, and bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

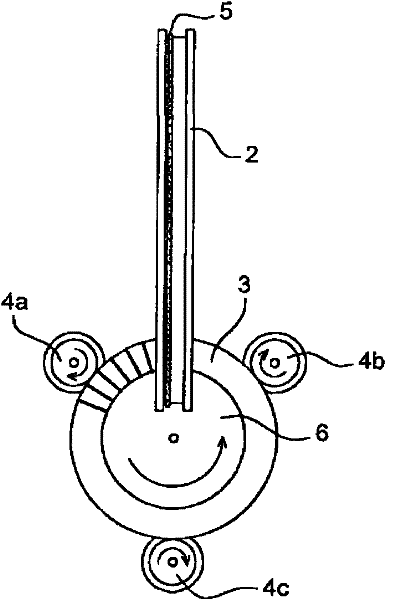

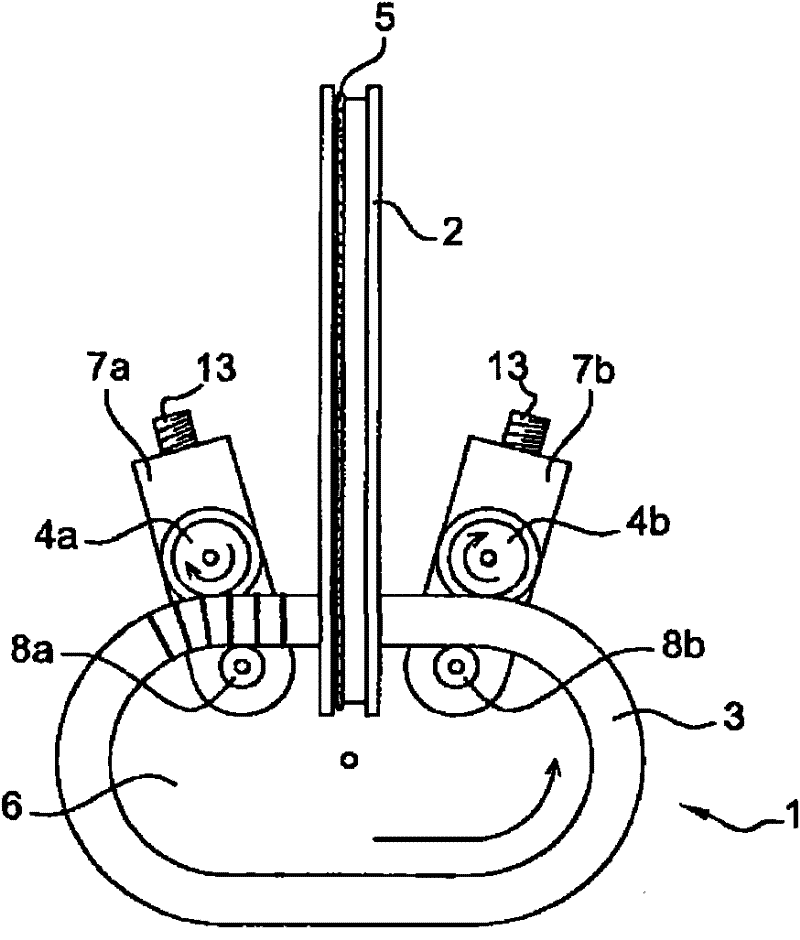

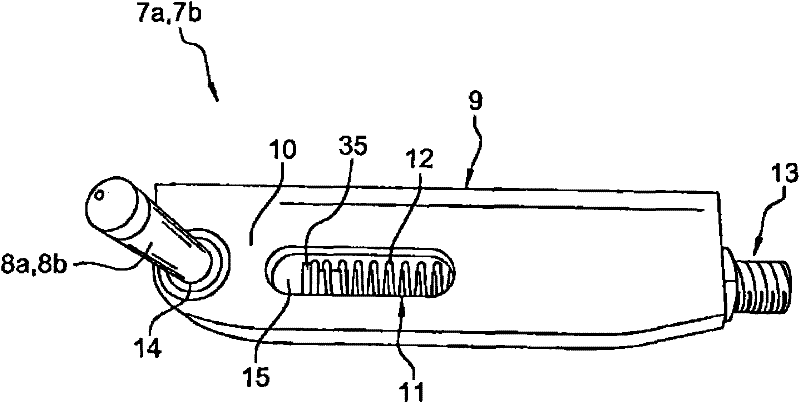

[0060] like figure 1 As shown, a coil winder, which is initially used to wind a core 3 or coil 3' having a toroidal shape, is subsequently adjusted to receive a transmission 1 according to the invention, said coil winder Comprising a shuttle 2 passing through the passage opening 6 of the core or coil 3' and feeding the copper wire 5 to be wound around the core or coil 3', and three drive rollers 4a, 4b and 4c.

[0061] In the following description, the terms "core" 3 and "coil" 3' are used interchangeably to denote a part on which the winding is carried out, with the core 3 in the first coil through the copper wire 5. When the covering layer is completed, it becomes the coil 3'.

[0062] To drive the core 3 or coil 3' in rotation, the three drive rollers 4a, 4b and 4c have gripping surfaces which are placed in contact with the outer contour of the core 3 or coil 3'.

[0063] Drive rollers 4 a and 4 b are provided on both sides of the shuttle 2 , and a third drive roller 4 c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com