Instrument for handling a joint component by way of a vacuum

A technology for manipulating parts and instruments, applied in the direction of hip joints, shoulder joints, joint implants, etc., can solve problems that cannot be ruled out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

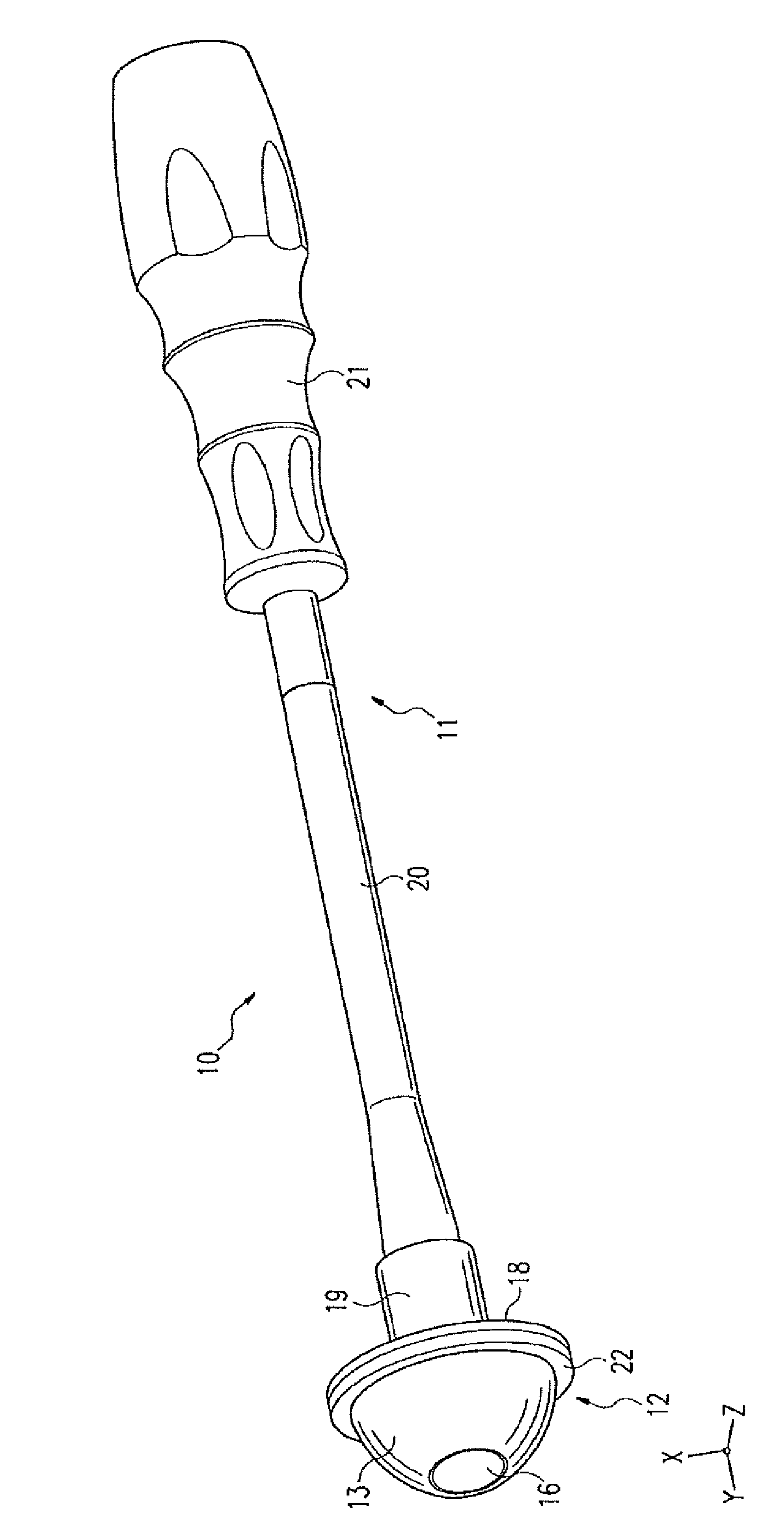

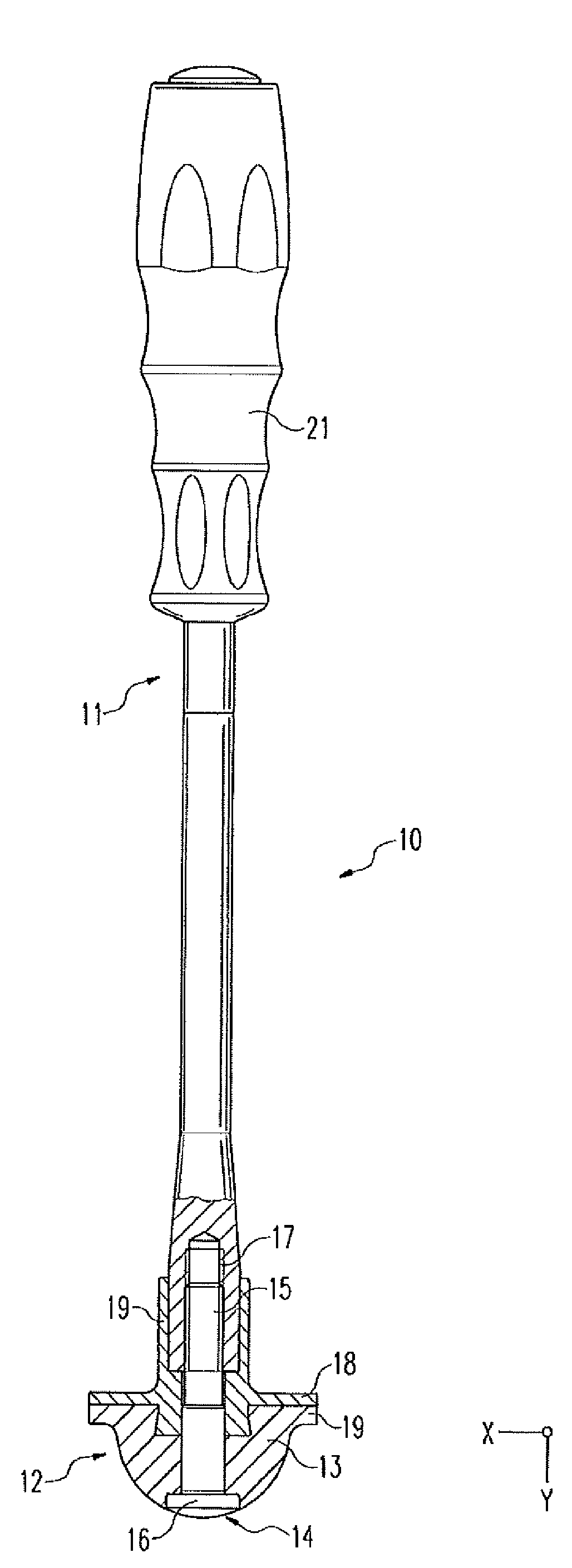

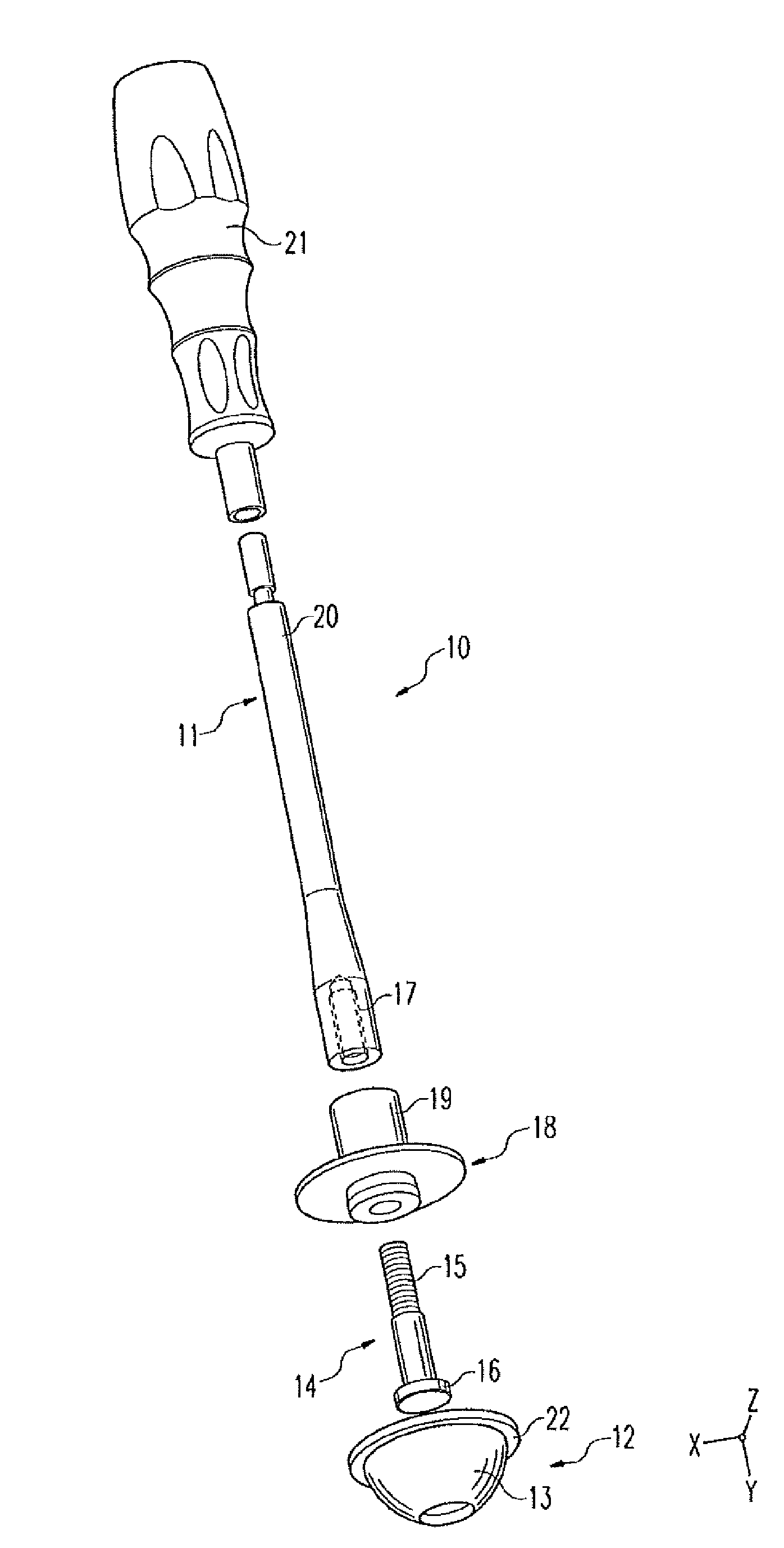

[0016] exist Figures 1 to 3 shows a hip socket inlay placement instrument or a shoulder socket inlay placement instrument, hereinafter simply referred to as placement instrument, which has an operating part 11 and a joint prosthesis not shown here that can be brought into sealing contact, such as a glenoid socket The suction element 12 on the articular surface of the The suction element 12 comprises a soft elastic molding 13 adapted to the articular surface, preferably made of silicone or the like, and which can be deformed by a pulling element in the form of a pulling screw 14, so that During abutment on the articular surface, a negative pressure is generated between the articular surface and the soft elastic molded part 13 . A pulling element in the form of a pulling screw 14 can be actuated from the actuating part 11, as will be explained in more detail below. The soft elastic molded part 13 comprises a hemispherical suction section which is adapted to the concave articu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com