Full-automatic snail tail cutter

A tail cutting machine, fully automatic technology, applied in the processing of crustaceans, slaughtering, food science, etc., can solve the problems of short cutting rate, non-sharp cutting knife, rolling dead snails, etc., so as to reduce the rolling time and prolong the survival time , the effect of reducing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The invention is further illustrated by the following examples.

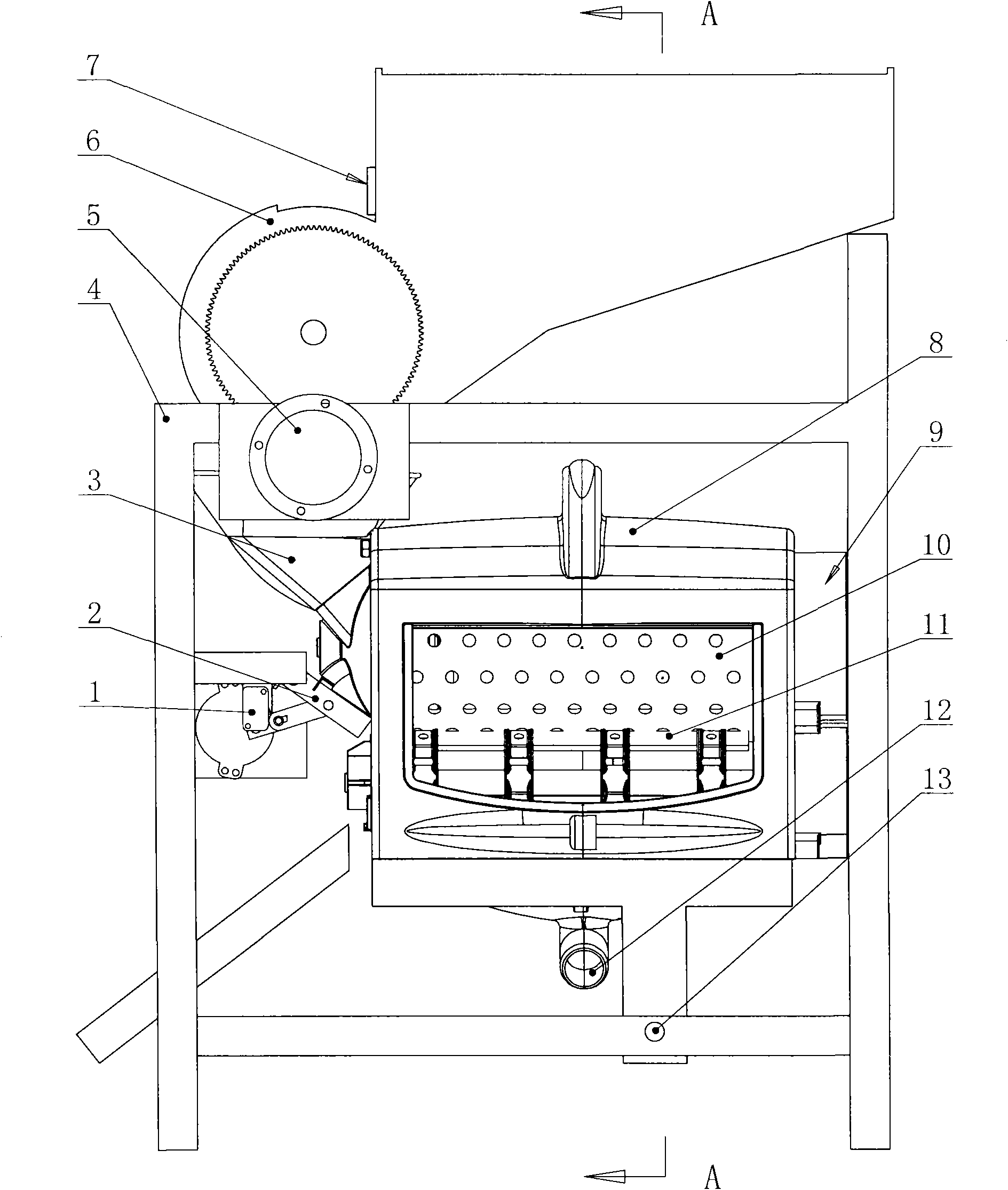

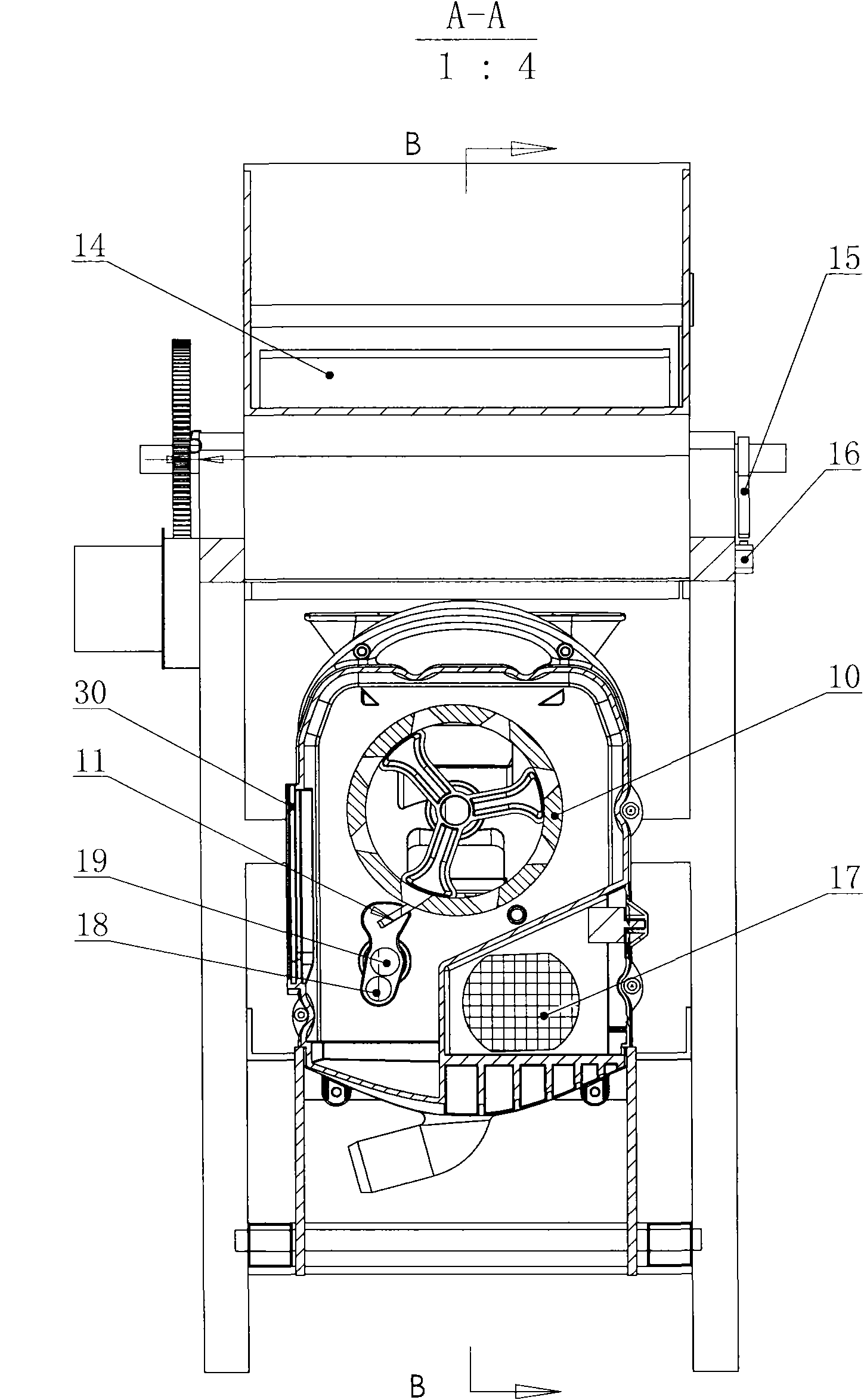

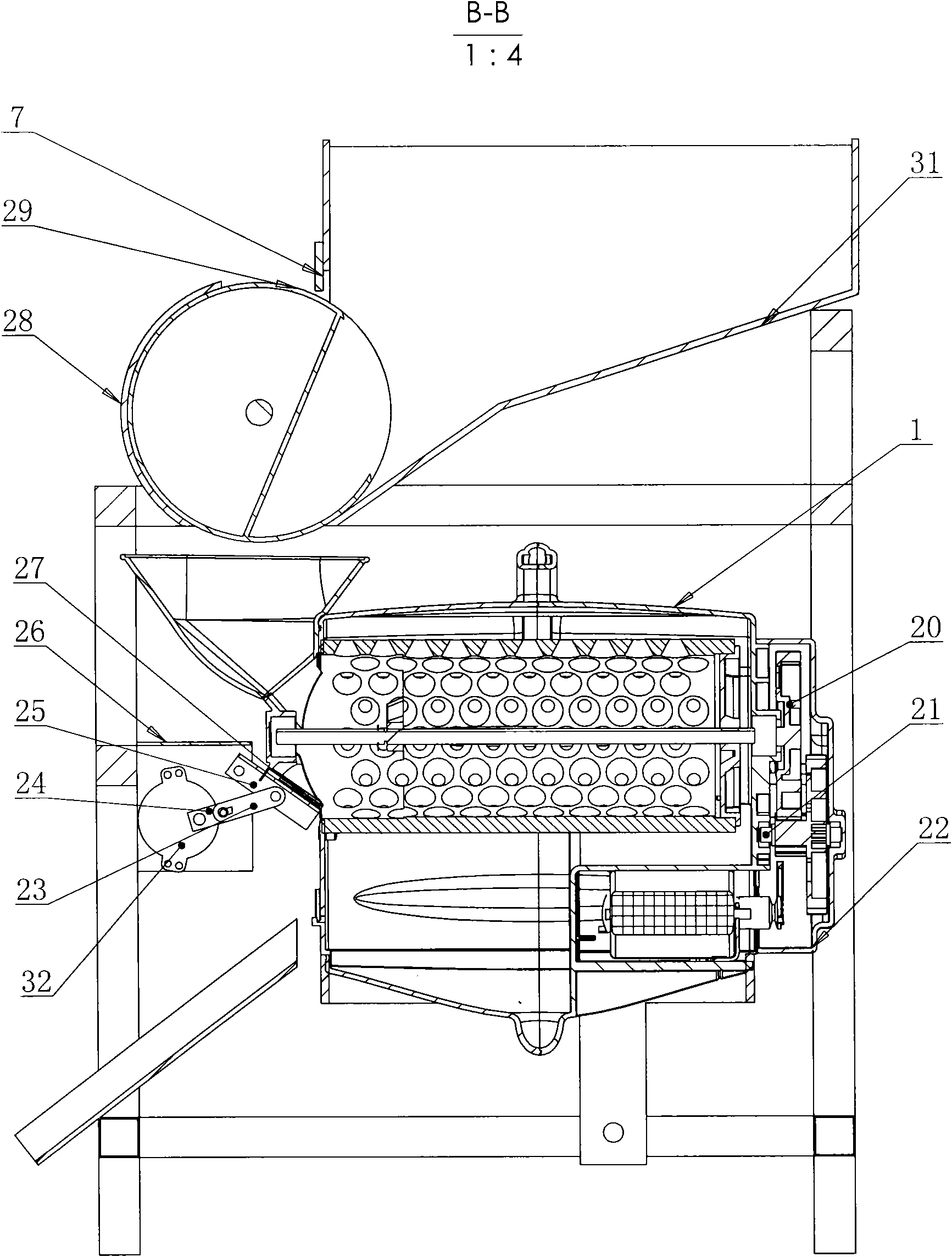

[0011] See figure 1 , figure 2 , image 3 , the full-automatic snail tail cutting machine of the embodiment of the present invention is made up of fuselage (4), feeder (6), tail cutting machine (8), export automatic door (2), control electric appliance; Cut tail machine (8) by machine Shell, feeding hopper (3), discharge port, probability outlet drum (10), tail cutting knife (11), gear reduction box (9), tail cutting machine motor (17); feeder is made up of hopper (31 ), a feeding drum (29), and a feeding motor (5). A rubber scraper (7) is installed on the hopper, and the feeding drum (29) is fixed on the shaft. One end of the shaft is connected to the feeding motor (5) through a gear Speed-down connection, switch pull-out bar (15) is installed on the axle; Exit automatic door is made up of door seat (26), export motor (32), rocking bar (24), connecting rod (23), door (25), and door ( 25) There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com