Rapid connection structure for ironing and brushing

A quick connection and ironing brush technology, which is applied in hand irons, washing devices, textiles and papermaking, etc., can solve the problems of complex, complicated assembly by manufacturers, difficult disassembly and maintenance, etc., and achieve simple assembly process, good sealing performance and stable connection reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

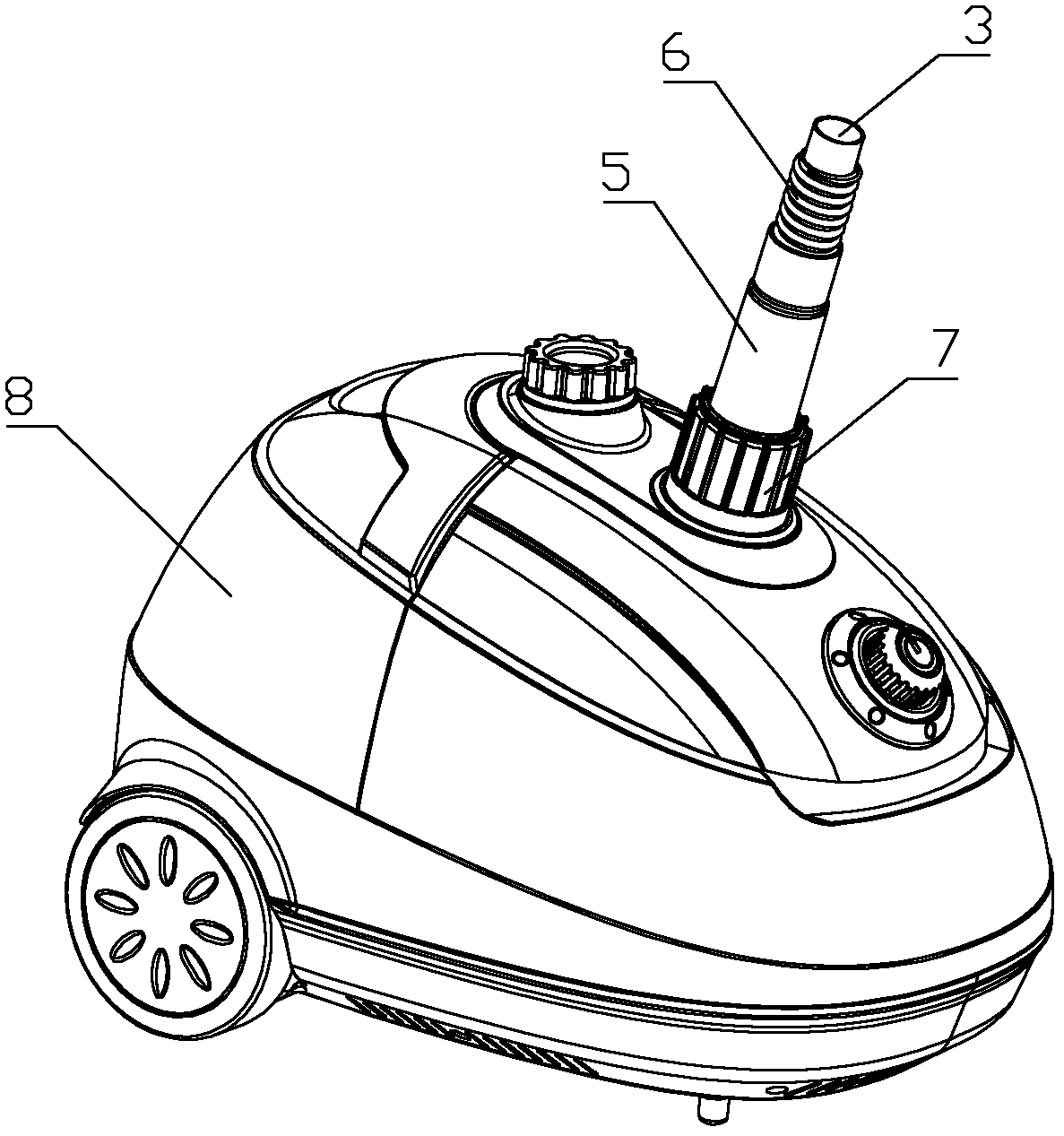

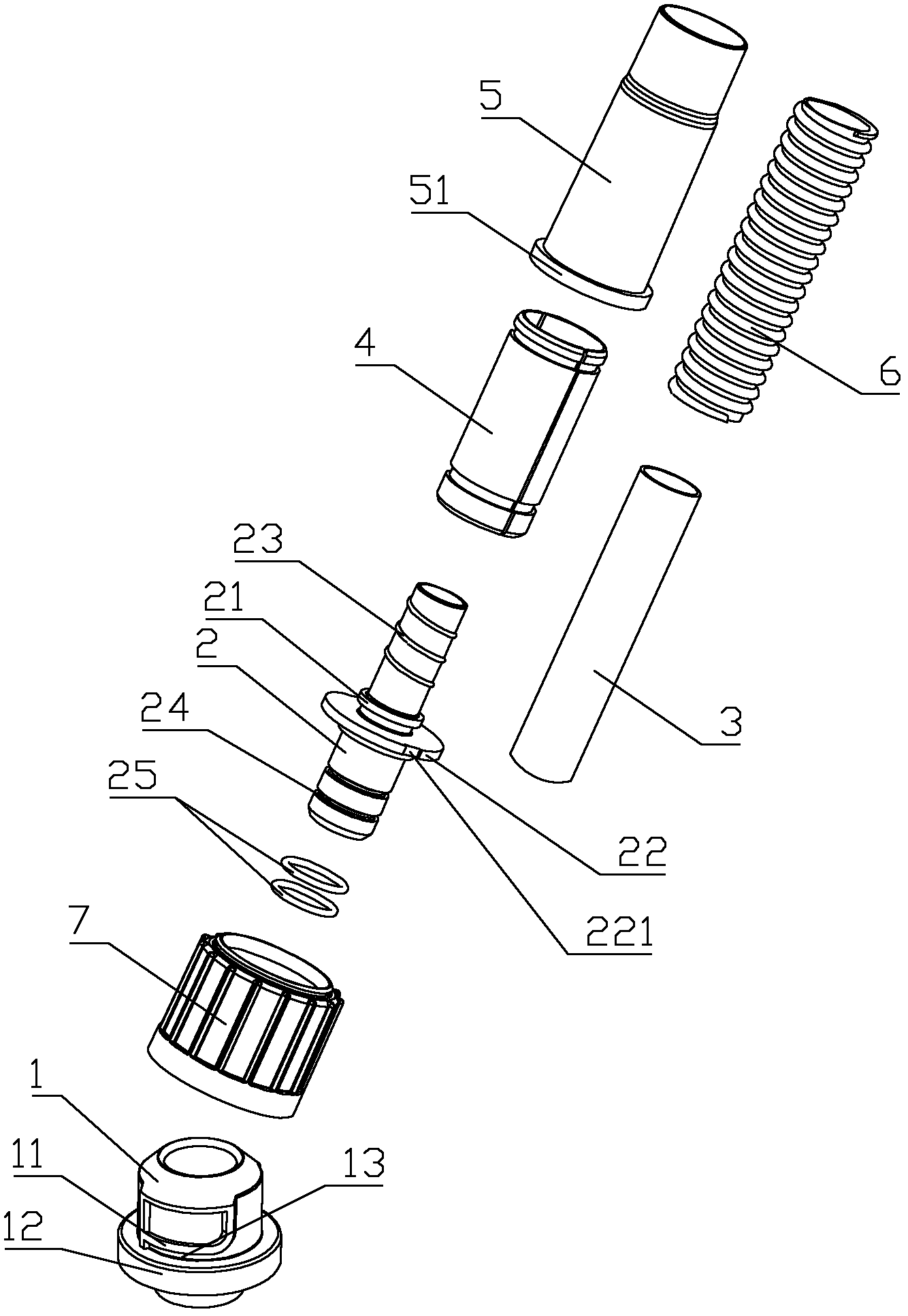

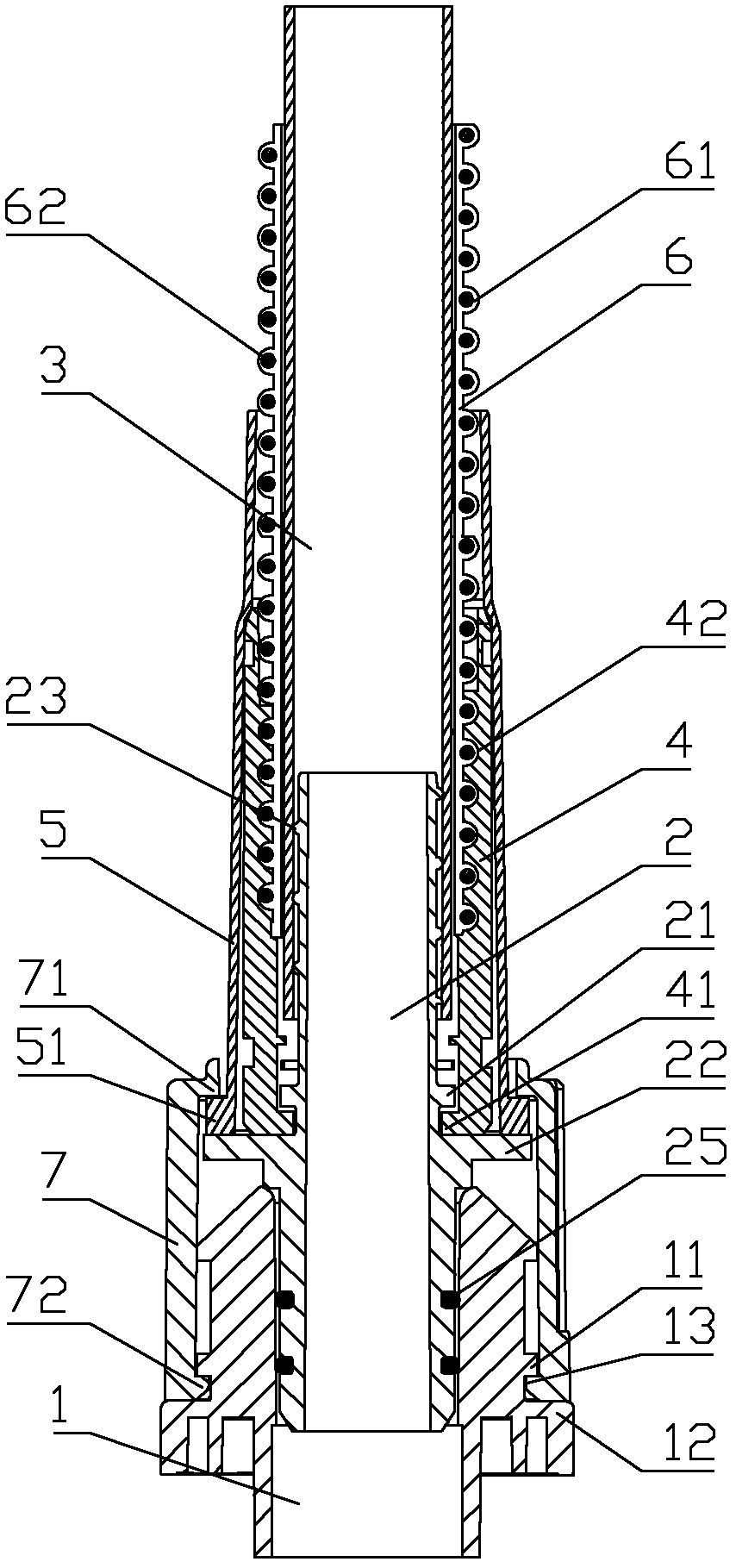

[0022] like Figures 1 to 5 Shown is a structural schematic diagram of an embodiment of the present invention, a quick connection structure for ironing brushes, including a socket 1, a steam joint 2 and a steam pipe 3 connected in sequence, the socket is set on the garment steamer housing 8 and is connected to the vaporizer 81 Connected, the lower end of the steam connector is connected to the socket, the upper end of the steam connector is connected to the steam pipe, the upper end of the steam connector is inserted into the steam pipe and a spiral rib 23 is provided on the outer surface of the upper end, the lower end of the steam connector is inserted into the socket and is placed outside the lower end. An annular groove 24 is arranged on the side, and a sealing ring 25 is arranged in the annular groove. A locking mechanism for fastening the steam pipe on the steam joint and a fixing mechanism for positioning the steam joint on the socket are provided on the steam joint.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com