Fireproofing closed observation window

An observation window and airtight technology, applied in the field of observation windows, can solve the problems of insufficient shape design of airtight observation windows, poor anti-corrosion performance, and no fireproof function of airtight observation windows. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

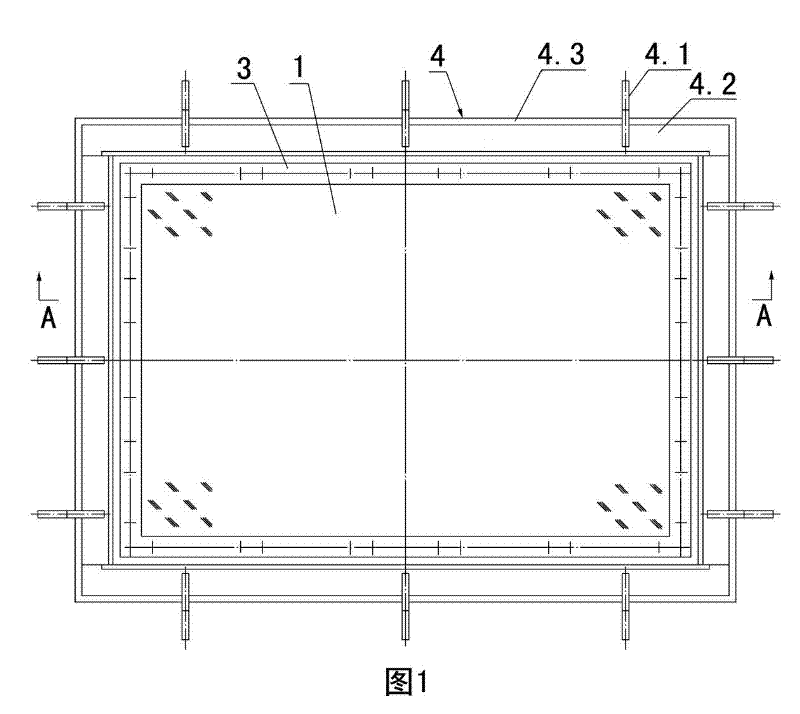

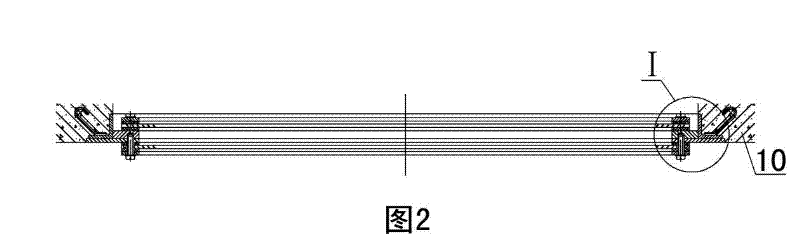

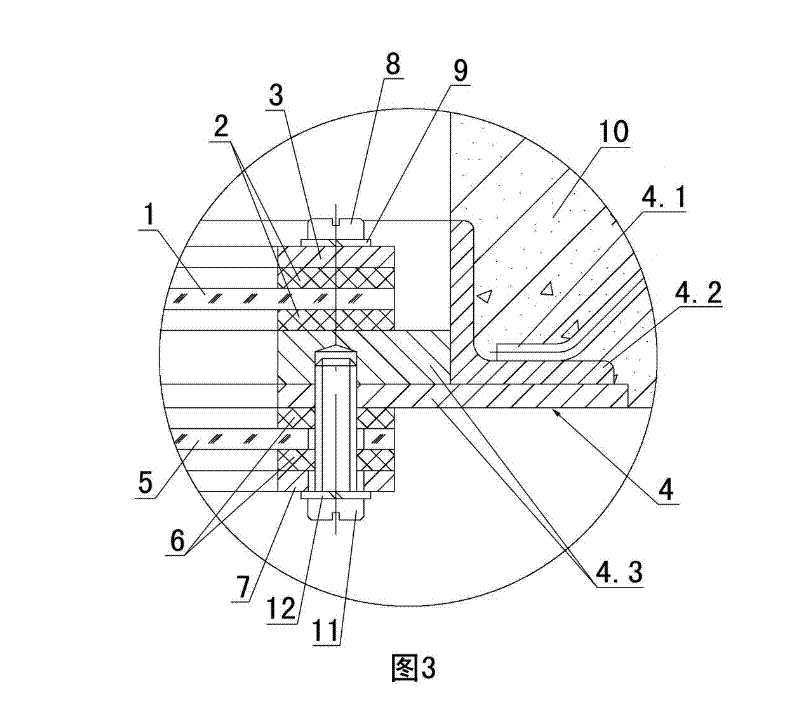

[0018] Examples see Figure 1-3 As shown, this fireproof airtight observation window includes an observation window frame 4 embedded in the observation hole of the airtight partition wall 10 and an observation window glass fixedly connected to the observation window frame 4 . The observation window frame 4 includes a pre-embedded anchor bar 4.1 pre-embedded in the airtight partition wall 10, an observation window frame base 4.2 with an L-shaped cross section welded to the pre-embedded anchor bar 4.1, and an observation window frame base 4.2 4.3 Welded high-strength pressure plates. The pre-embedded anchor bar 4.1 can be a straight bar or a bent bar, and a bent bar is used in this embodiment. The high-strength pressure plate 4.3 is composed of a thin plate and a thickened plate, the thin plate is welded to the outer surface of the observation window frame base 4.2, and the thickened plate is welded to the connection corner of the thin plate and the observation window frame bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com