Reciprocating hydraulic system

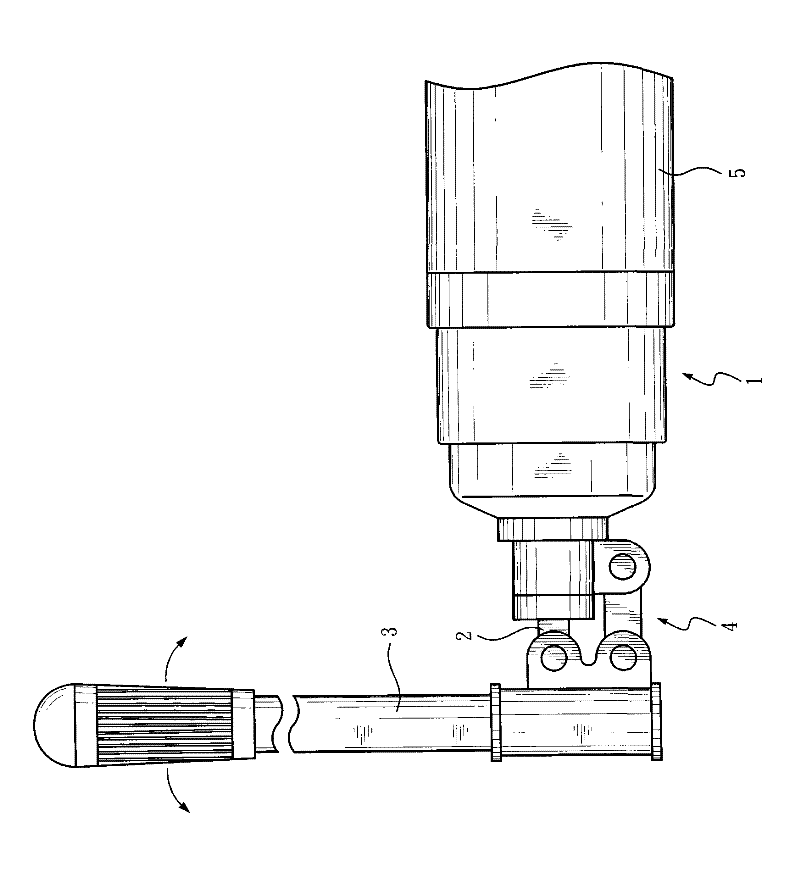

A hydraulic system, reciprocating technology, used in hand-held tools, fluid pressure actuation devices, remote control motors, etc., can solve the problems of easy wear and damage of parts, size and strength limitations, long-term wear and tear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

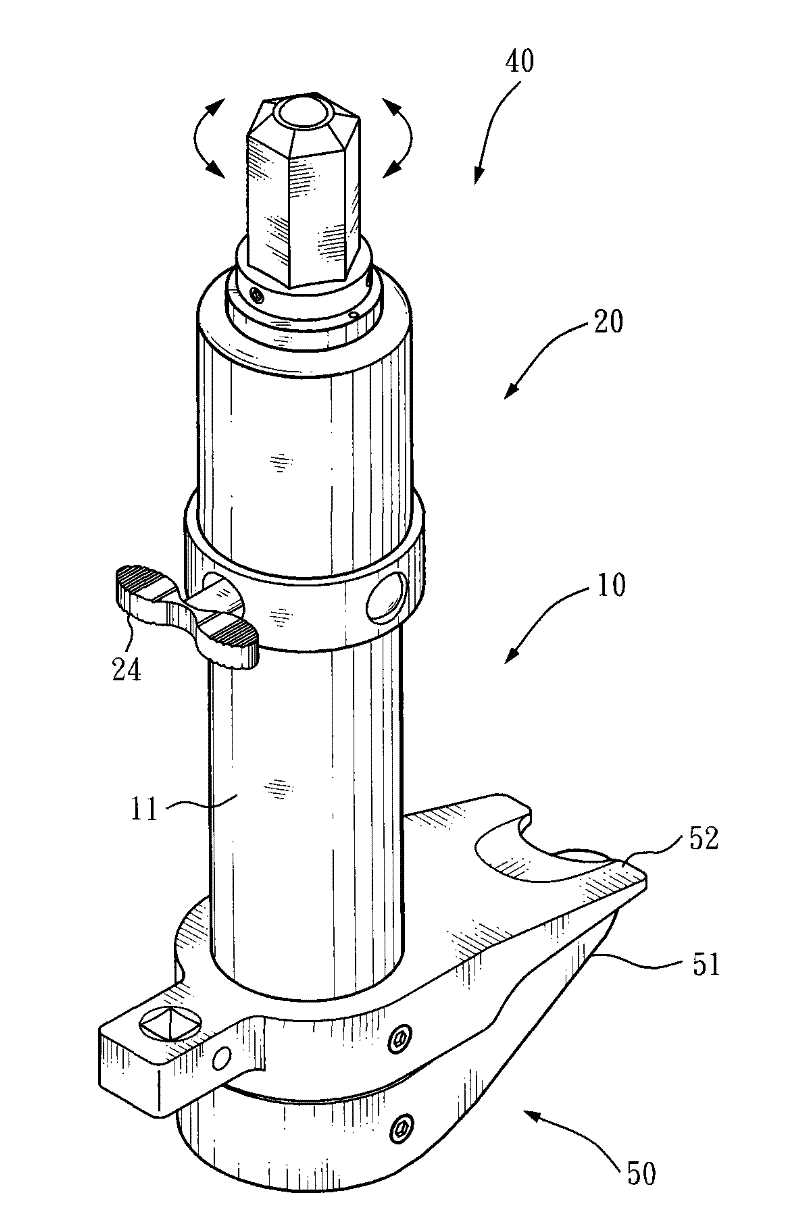

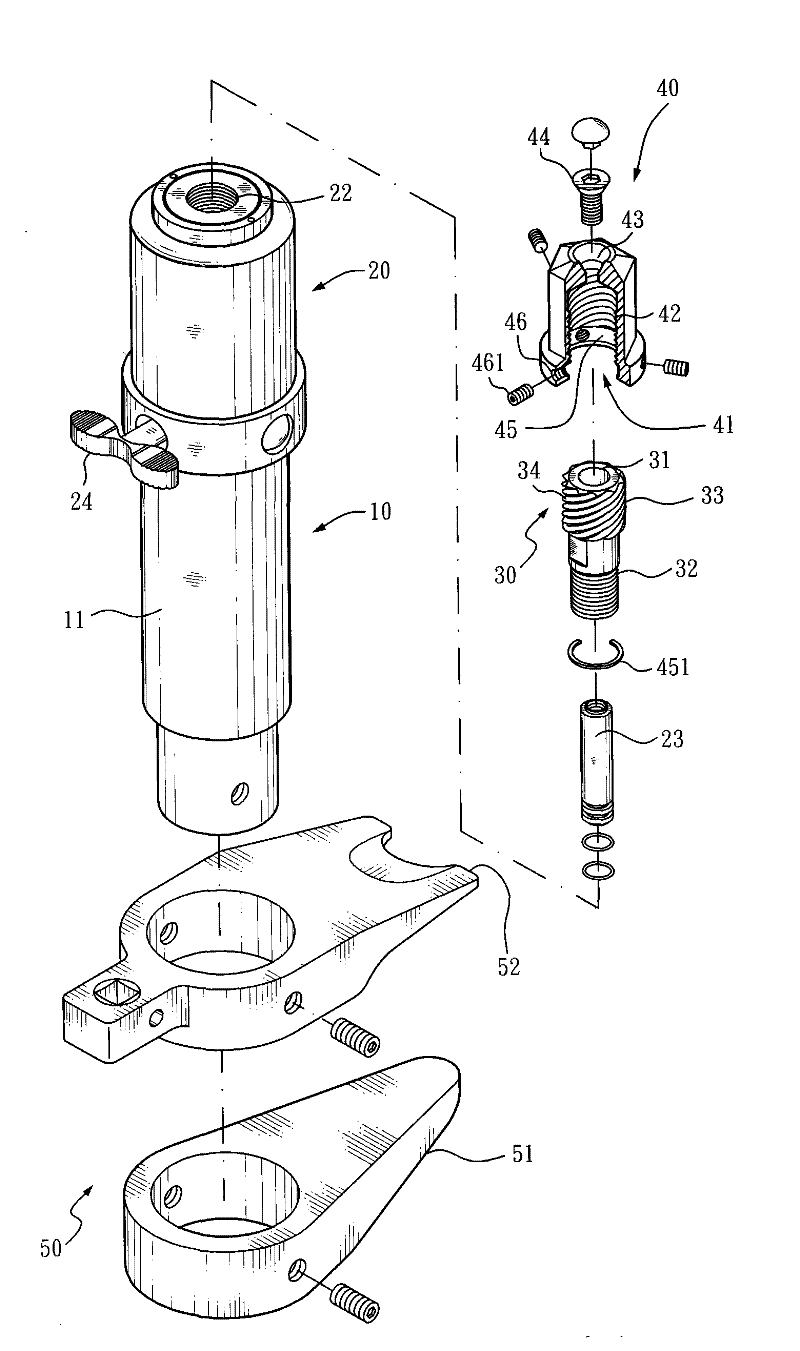

[0033] like Figure 2 to Figure 7 As shown in the drawings, a reciprocating hydraulic system of the present invention mainly includes:

[0034] A hydraulic output device 10 includes a hydraulic cylinder 11, and an output shaft 12 is arranged in the hydraulic cylinder 11, and the hydraulic cylinder 11 can drive the output shaft 12 to protrude from the hydraulic cylinder 11 by the input liquid pressure.

[0035] A hydraulic input device 20, which is a common hydraulic or oil pressure generating device, includes an oil storage tank for storing liquids such as hydraulic water or oil and a hydraulic pump (not shown), the oil storage tank is used The pipeline communicates with the hydraulic cylinder 11 through the hydraulic pump, wherein the hydraulic pump has an input shaft 23 exposed on the surface of the hydraulic input device 20, and the input shaft 23 can drive the hydraulic pump to move from the oil storage tank. The hydraulic pressure is sent to the hydraulic cylinder 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com