Invisible magnetic connecting device

A magnetic connection and invisible technology, applied in the direction of thin plate connection, furniture connection, connection components, etc., can solve the problem of detachable connection parts exposed outside the connection plate, and achieve the effect of convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further explanation is given below in conjunction with accompanying drawings:

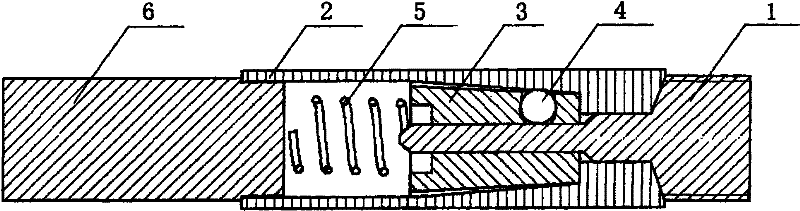

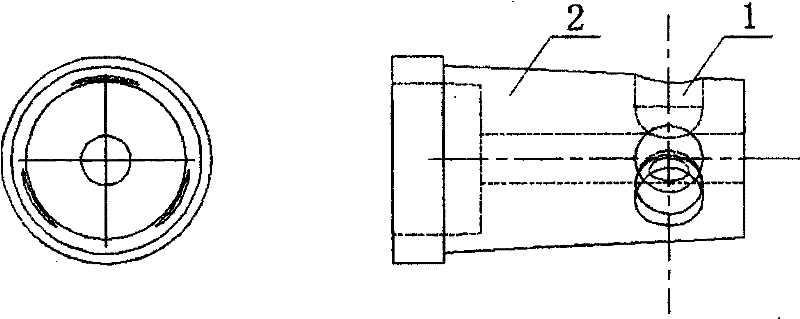

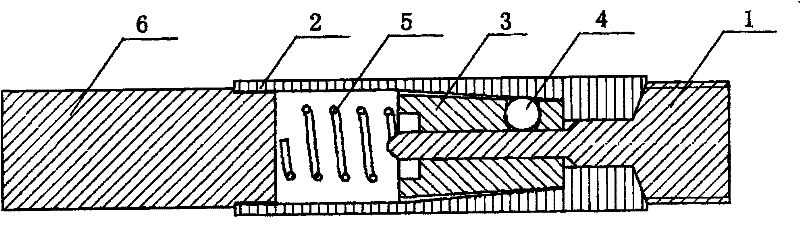

[0017] Such as figure 1 As shown, the invisible magnetic connection device of the present invention consists of two parts: an inserting part and a locking part.

[0018] Before installation, the threaded section of the insert 1 is connected with the expansion bolt previously fixed in the connecting body. Put the ball 4 into the radial through hole of the ball sleeve 3, then put the ball sleeve 3 with the ball 4 into the connecting sleeve 2, and then put the spring 5 and the pressure rod 6 into the connecting sleeve. Press the assembled locking piece into the pre-drilled hole of another connecting body to ensure that the locking piece is firmly connected with the connecting body.

[0019] When installing, insert the insert 1 into the positioning hole of the locking piece connecting sleeve 2 and the hole of the ball sleeve 3, and the ball 4 is always stuck on the insert section of the insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com