Explosionproof electrical connector, plug and socket thereof

A technology for electrical connection devices and sockets, which is applied in the direction of two-part connection devices, parts of connection devices, connections, etc., can solve potential safety hazards, easy occurrence of electric sparks and other problems, and achieve avoidance of electric sparks, high safety performance, and good waterproof performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

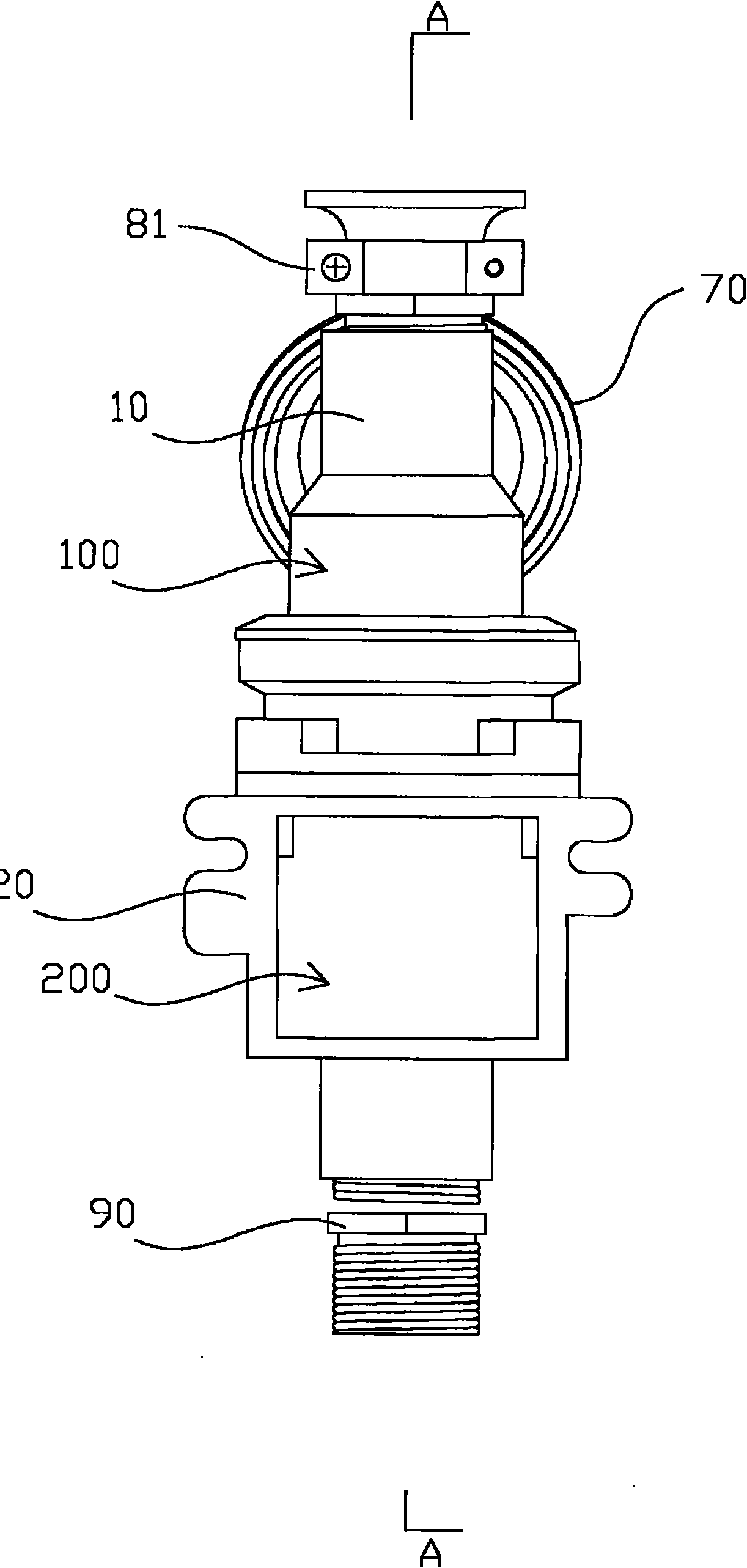

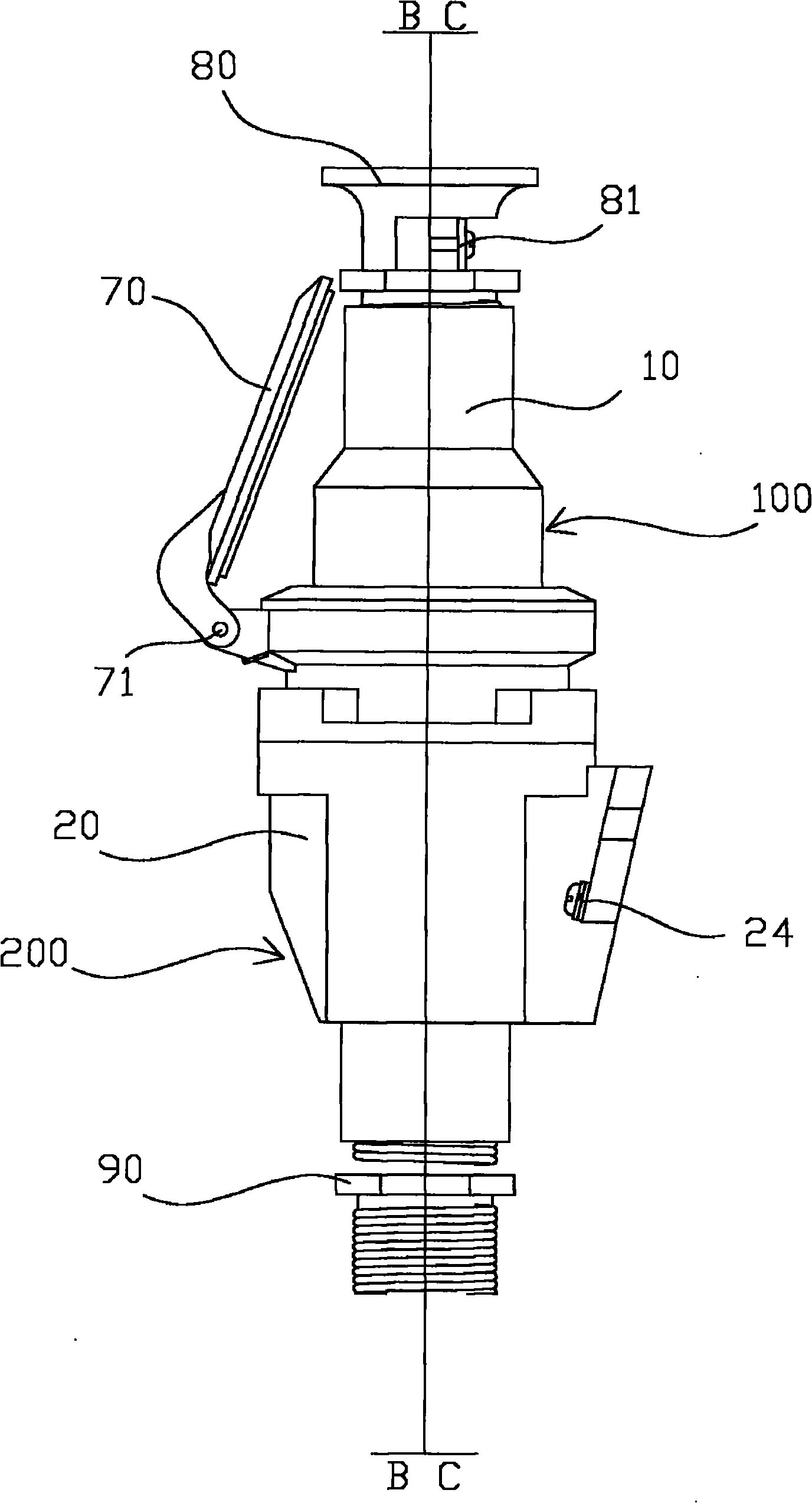

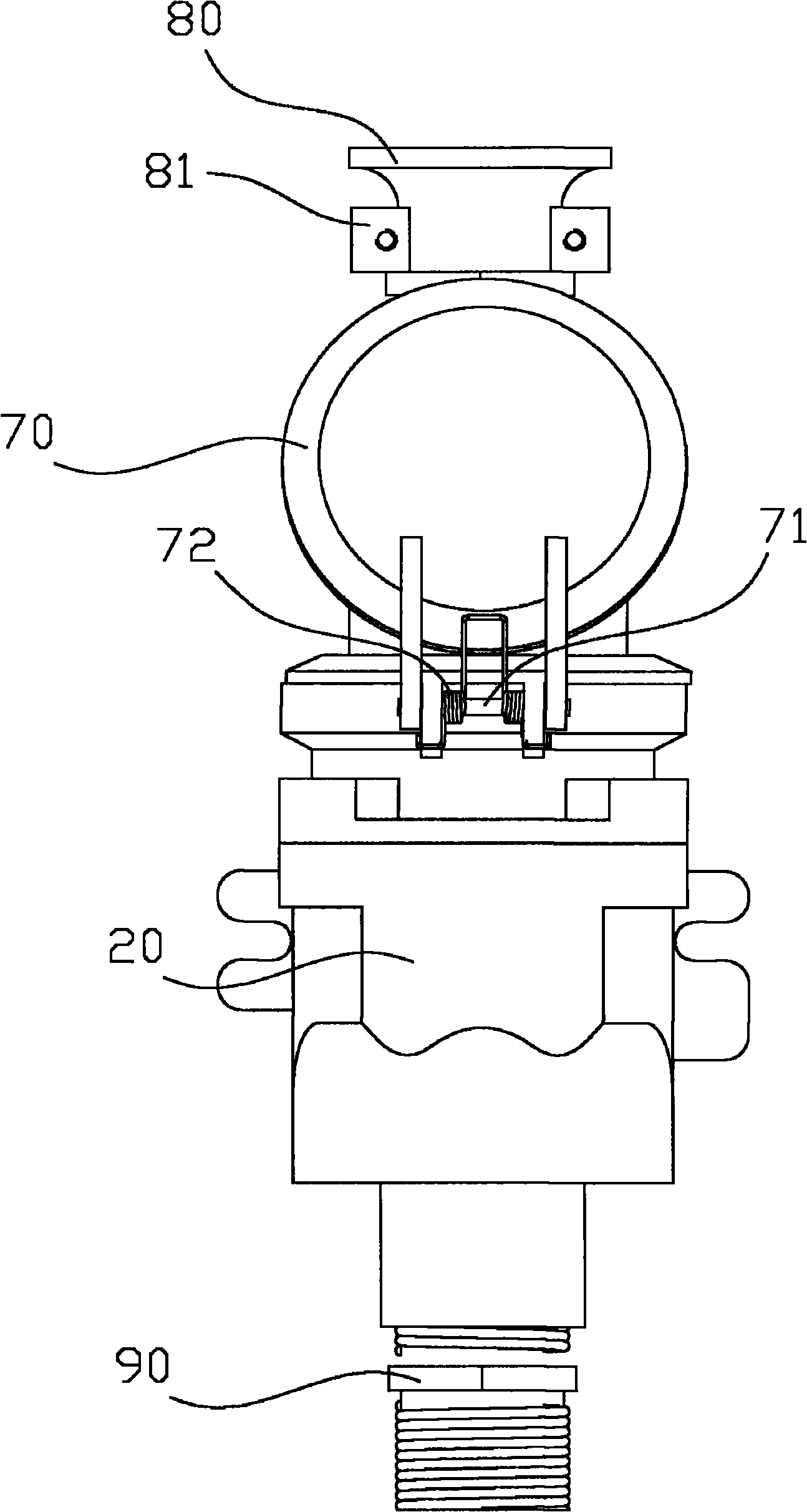

[0054] like Figure 1A ~ Figure 1C As shown, the explosion-proof electrical connection device of the present invention includes a plug 100 and a socket 200, wherein the plug 100 is connected to an electrical device (not shown in the figure), and the socket 200 is electrically connected to a power supply. When the plug 100 is inserted into the socket 200 and electrically connected , can realize the electrical connection between electrical equipment and power supply. The socket 200 has a ground terminal 24, such as Figure 1B shown.

[0055] The plug 100 has a plug housing 10 and a plug assembly 30, such as Figure 2A As shown, the plug assembly 30 has a plug plug 300, and two opposite first contacts 31 and 32 are sequentially arranged on the outer wall of the plug plug from near to far from the insertion end face of the plug plug 300. , two opposite second contacts 33 and 34 , and a clip 35 , and the clip 35 is located directly above one of the second contacts, such as direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com