Apparatus for folding and stacking vinyl bags

A technology of laminating device and plastic bag, which is applied in the direction of folding thin materials, stacking receiving device, packaging, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

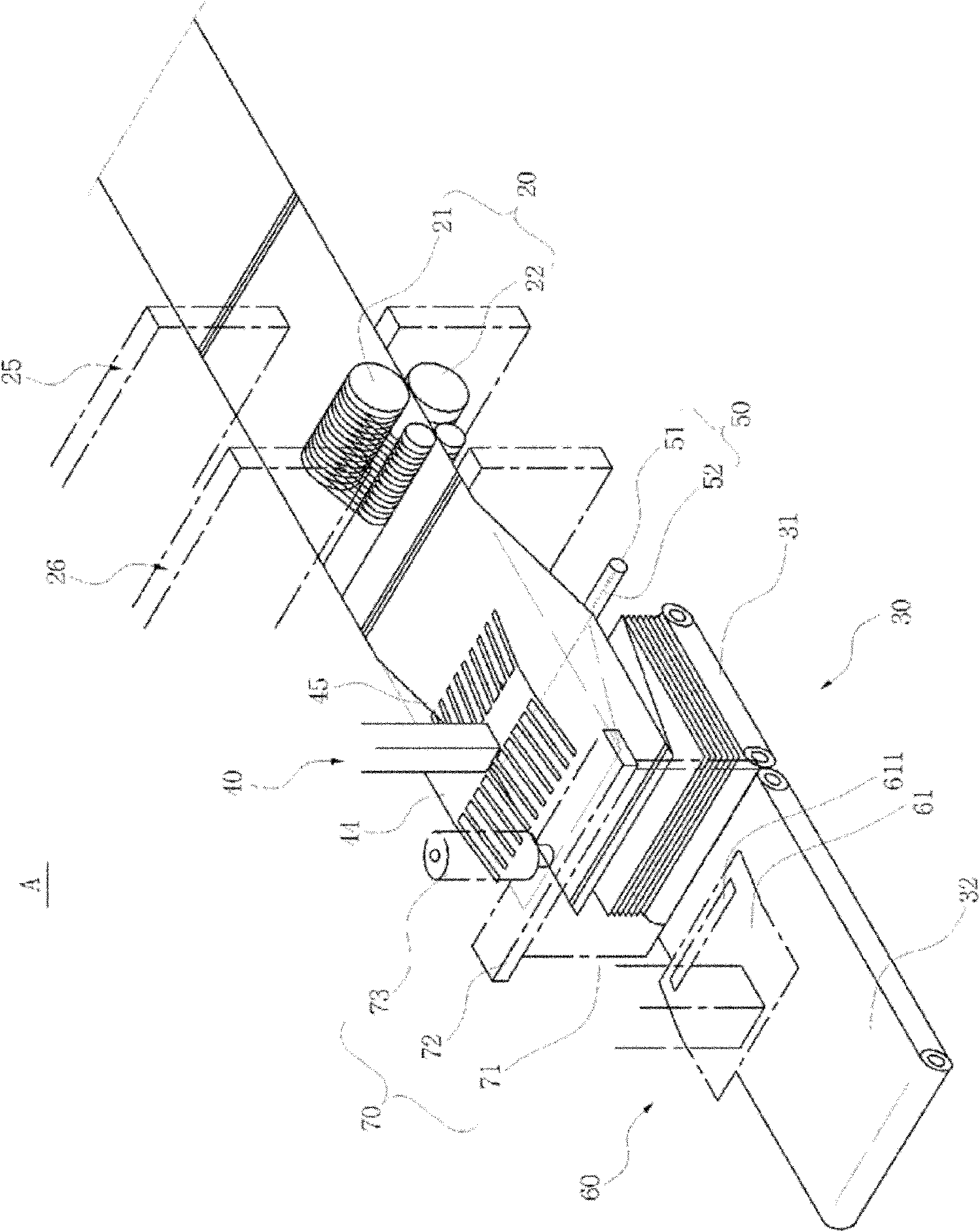

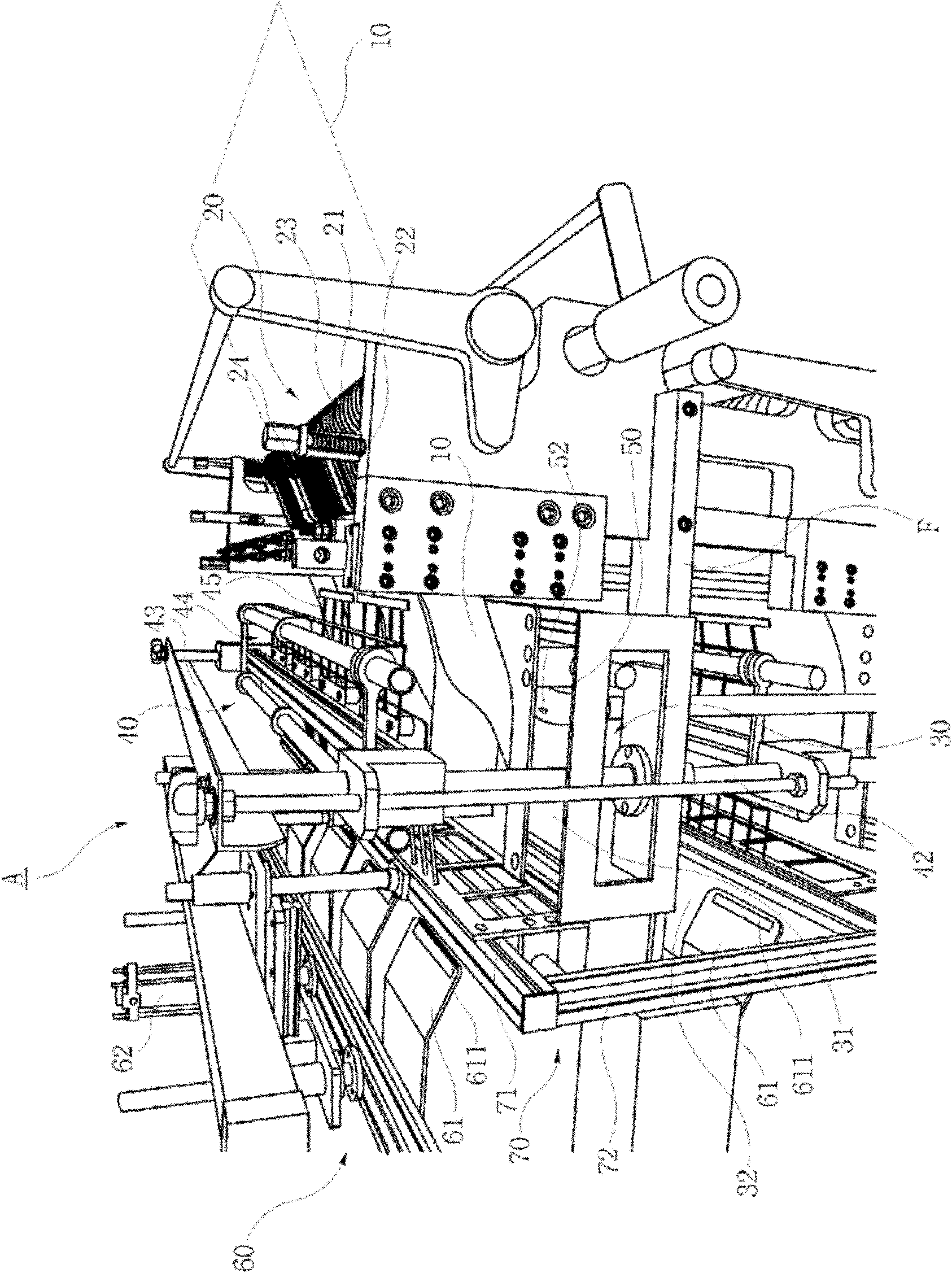

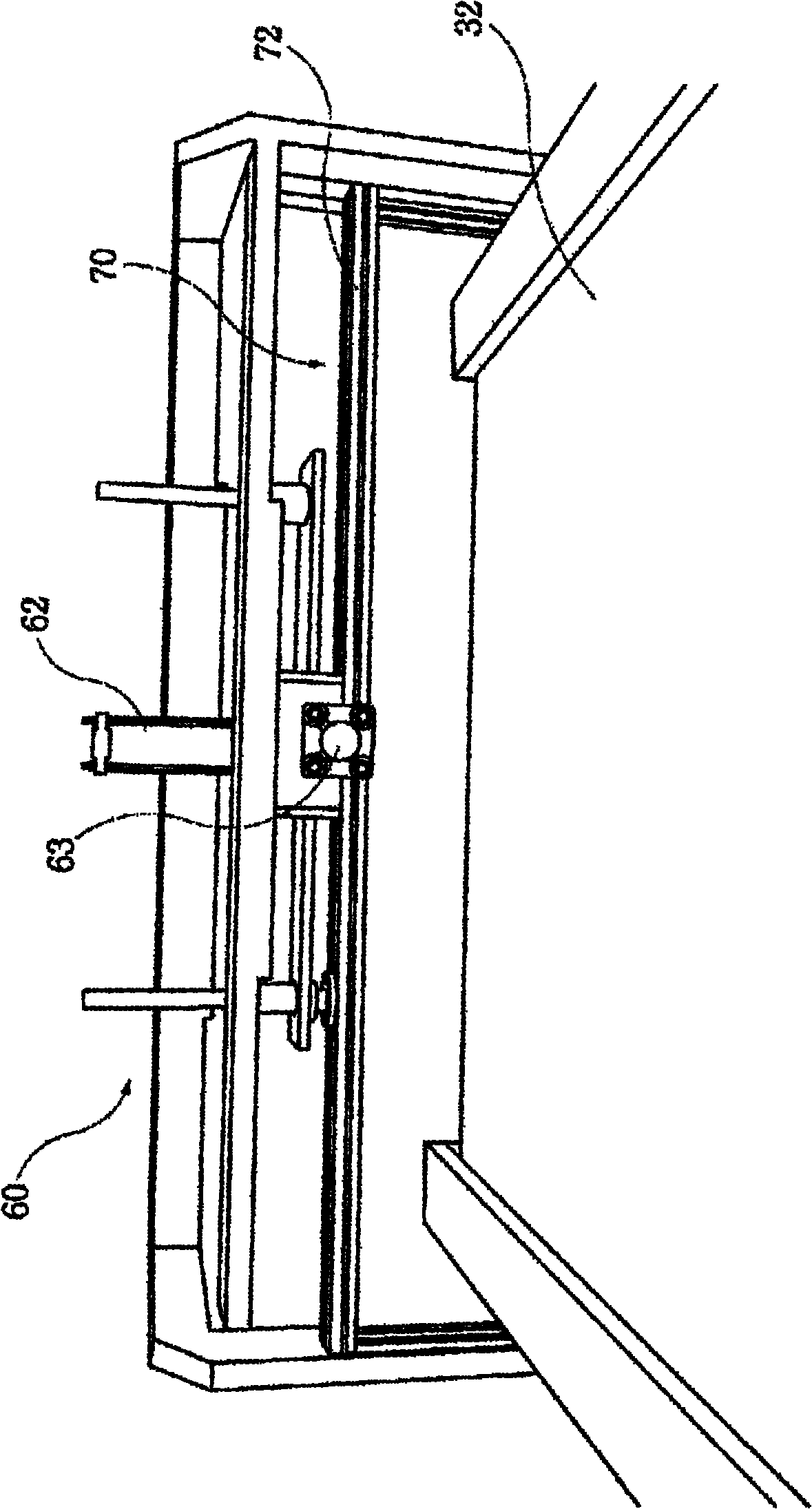

[0026] Hereinafter, it will be described in detail with reference to the accompanying drawings.

[0027] Such as Figure 1 to Figure 10 As shown, the plastic bag folding and laminating device (A) according to the present invention includes a conveying device (20) for conveying plastic bags (10), a laminating device (30), a pressing device (40) and a fixed suction device (50).

[0028] Said plastic bag (10) here is that synthetic resins such as polyvinyl chloride, polyethylene are calendered and formed, forms shearing line and heat-sealed part by certain interval, as using certain tension force, shearing line part can be cut.

[0029] In addition, the above-mentioned delivery device (20) has the function of continuously delivering the plastic bag (10) through the upper delivery roller (21) and the lower delivery roller (22), and the upper delivery roller (21) and the lower delivery roller (22) are conveyed by two rows. roll composition.

[0030] Moreover, the upper conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com