Method for efficient and localized production of shoes

A technology of footwear and manufacturing units, which is applied in the direction of footwear, data processing applications, instruments, etc., can solve problems such as limitations, and achieve the effect of avoiding high costs and reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

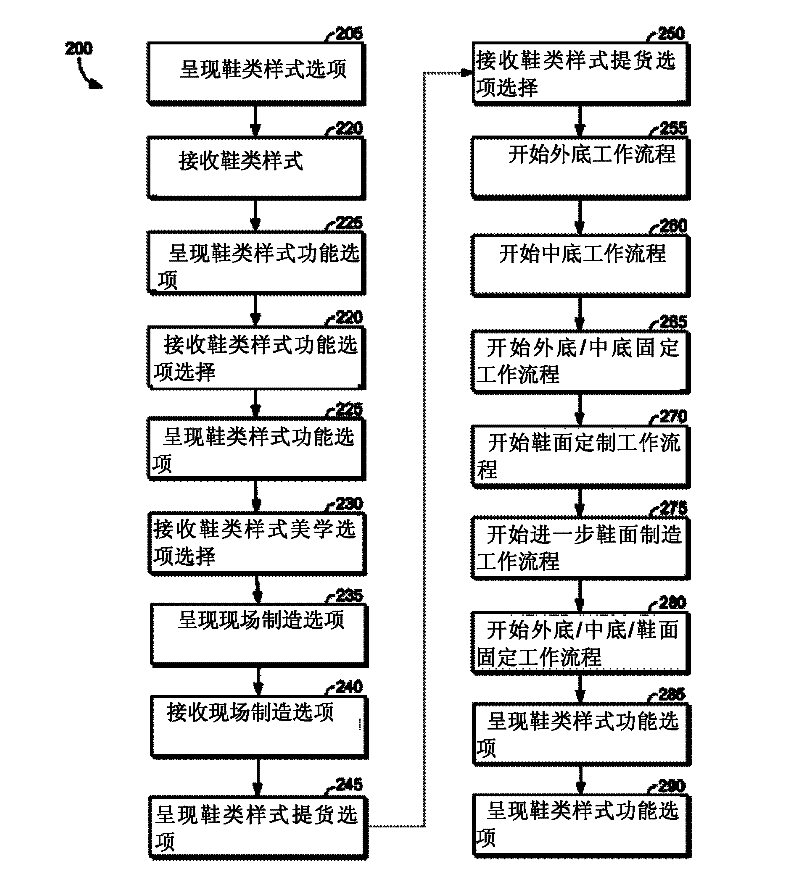

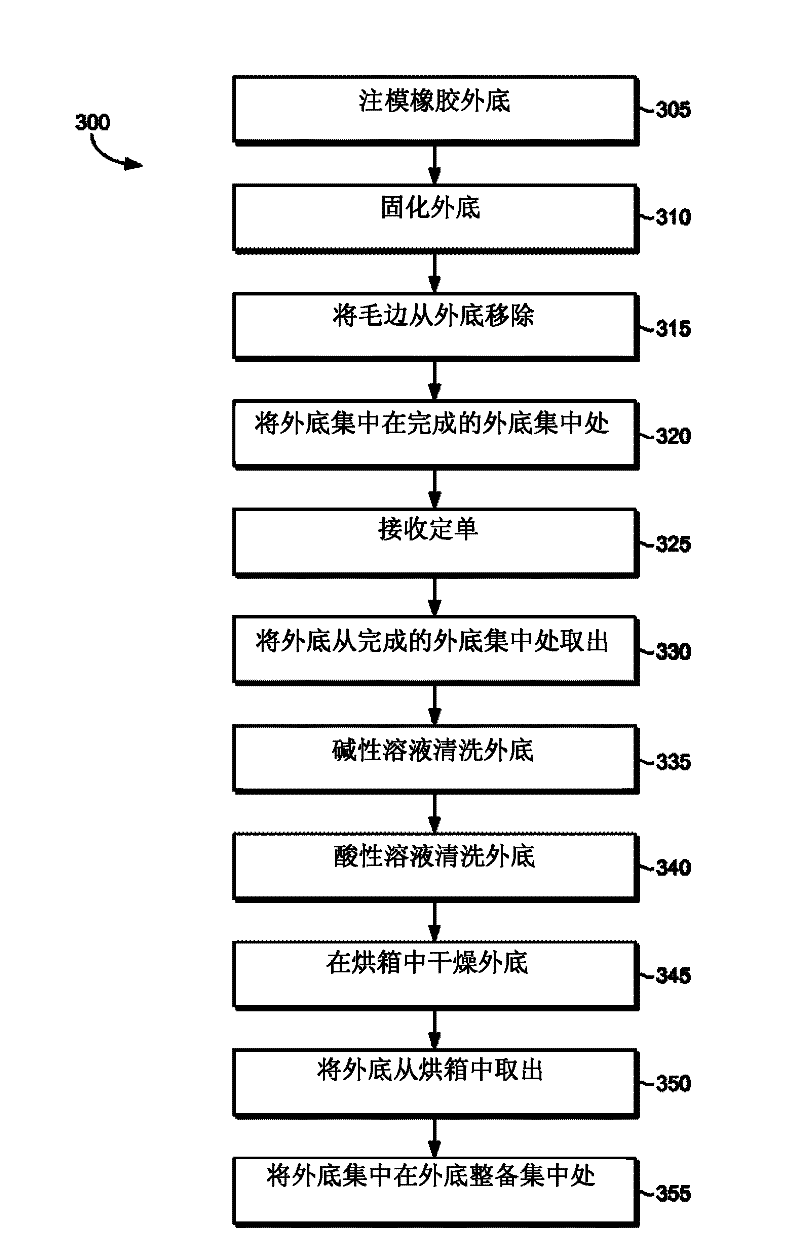

[0035] The subject matter of the present invention is described in detail here to satisfy statutory requirements. However, the description itself is not intended to limit the scope of protection of the present invention. Rather, the inventors have contemplated that the claimed subject matter of the present invention may also be implemented in other ways, in combination with other present or future technologies, thereby including steps different from those described in this document, or different from those described in this document. A combination of similar steps. Moreover, although the term "step" is used herein to denote a method employing distinct elements, the term should not be construed to imply any specific order among the various steps disclosed herein, unless explicitly stated within an individual step.

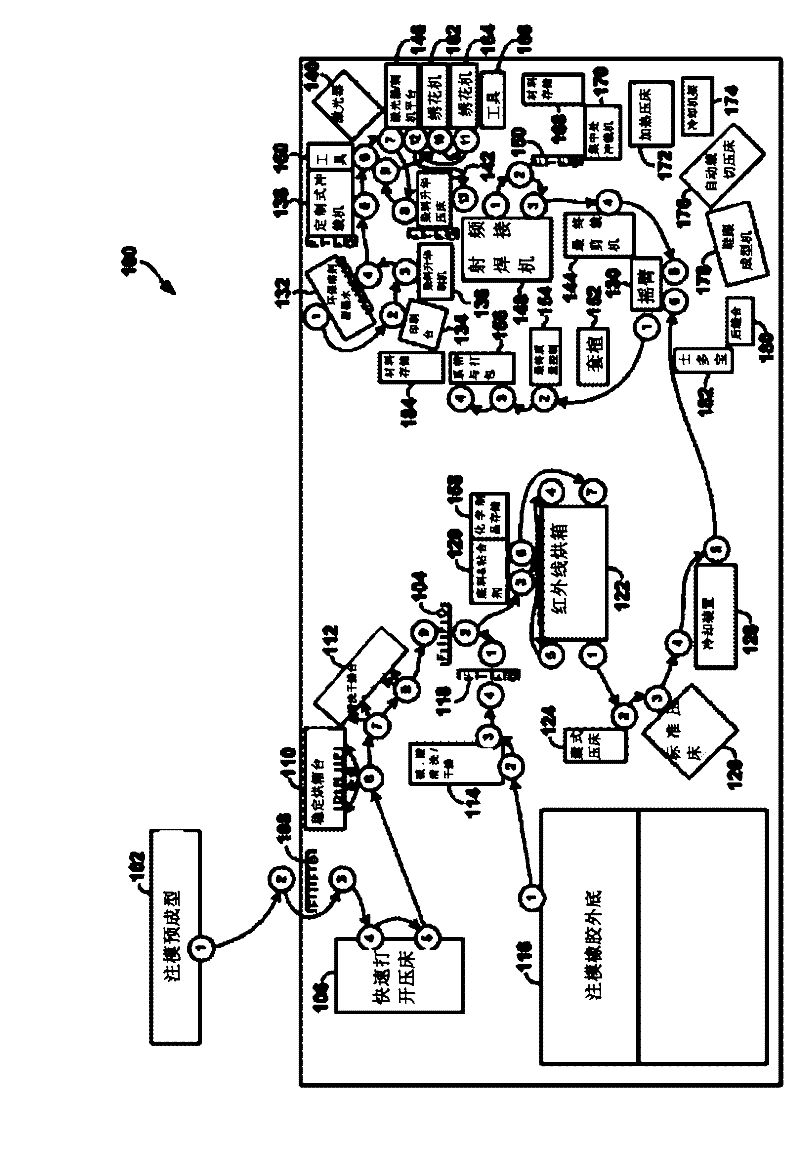

[0036] Embodiments of the present invention may provide methods of efficiently manufacturing articles of footwear that may meet the needs of geographic locations. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com