Gluing anti-corrosion process of vehicle cavity structure and gluing shielding tool for process

A cavity and process technology, applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of obtaining ideal anti-corrosion coating effect, large investment, high cost, etc., to ensure the quality of coating and gluing work efficiency, less investment, and high cost-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

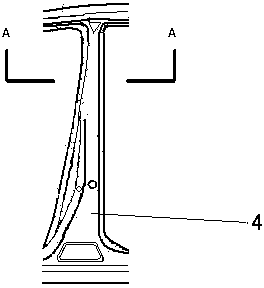

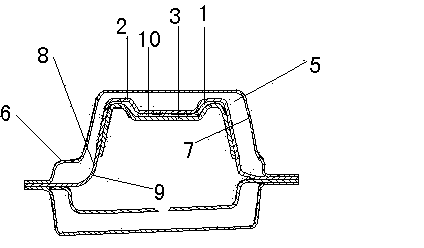

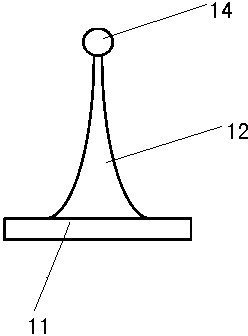

[0025] Such as figure 1 and figure 2 In the column cavity structure shown in the car body, the main reinforcement plate 2 and the auxiliary reinforcement plate 3 will form the main and auxiliary reinforcement plate cavity 1 after welding, and the maximum distance between the main reinforcement plate 2 and the auxiliary reinforcement plate 3 is less than 5mm, so it cannot meet the electrophoresis Penetration requirements. A gluing anticorrosion process for an automobile cavity structure is adopted, and a gluing covering tool is used in the process. The tool includes a cover plate and a handle. The cover plate is circular and its area is larger than any assembly hole on the center column. A circular cavity is dug out on one side of the cover plate, and the other side is connected with the bottom end of the handle. The handle is a bottleneck-shaped rotating body , the rotating body takes half of the "eight"-shaped arc as the bus line, and the central axis of the cover pl...

Embodiment 2

[0027] Such as figure 1 and figure 2 In the center column cavity structure shown in the car body, the side wall outer panel 6 and the main reinforcement plate 2 will form the center column outer cavity 5 after welding, and the side wall outer panel 6 and the main reinforcement plate 2 lack enough electrophoresis holes, which cannot meet the Electrophoretic penetration rate requirements, but in order to ensure the strength of the center column 4, it is not allowed to open too many holes on the side wall outer plate 6 and the main reinforcement plate 2 to meet the process conditions of electrophoretic film formation. For this reason, a glue coating anti-corrosion process for automobile cavity structure is adopted. First, before the welding process is implemented, expansion glue is evenly coated on the inner surface 7 of the side wall outer panel and the outer convex surface 8 of the main reinforcement plate. For expansion glue with a rate of 50%, the thickness of the glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com