Fender support made of composite materials

A composite material and fender technology, which is applied in the field of composite fender brackets, can solve the problems of loosening of support rods and fixed bases, easy corrosion and rust of metal fender brackets, and high strength, so as to prevent rotation and reduce Product weight and production cost, the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

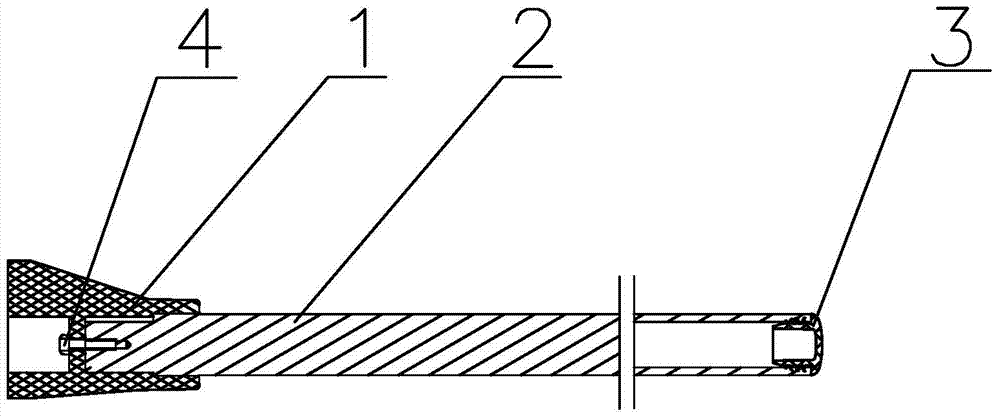

[0009] Such as figure 1 As shown, the present invention includes a base 1, a pipe body 2, a plug 3, and a bolt 4. One end of the pipe body 1 is coated with sealant and fixed inside the base 1 by the bolt 4, and a plug 3 is installed at the other end. 2 The cut cross section is elliptical or other polygonal, the base 1 is made of PA66+GF30, SMC resin or thermosetting composite material by injection molding or compression molding, and the tube body 2 is made of unsaturated resin, phenolic resin, epoxy Resin, PA66+GF30 or thermoplastic composite material is formed by injection, pultrusion or compression molding.

[0010] Through the above arrangement, the main components of the present invention adopt non-metallic materials, which fundamentally solves the problem of easy corrosion and rusting of metal fender brackets, and the use of the above-mentioned materials has light specific gravity and high strength, which can reduce product weight and production costs, and at the same time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com