Rotating shaft sealing structure

A rotating shaft seal and rotating shaft technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of large resistance, easy wear of the inner edge surface of the seal, and complicated maintenance process, so as to reduce the rotation resistance and use cost Low, maintain the effect of smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

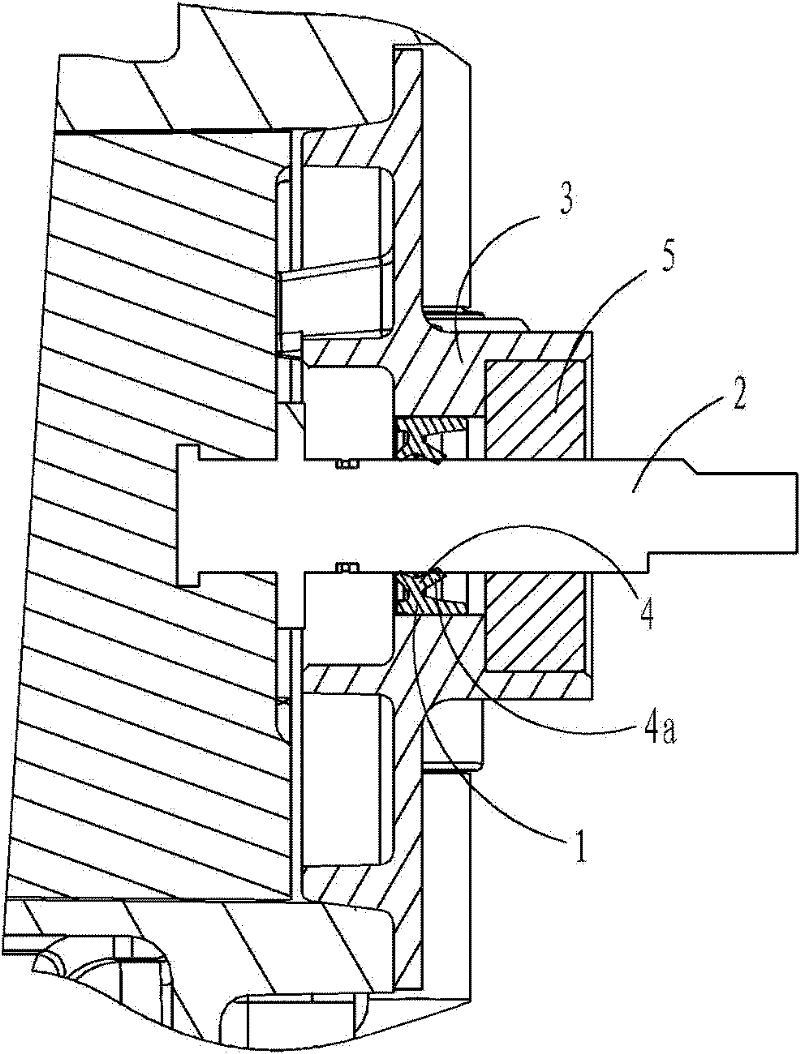

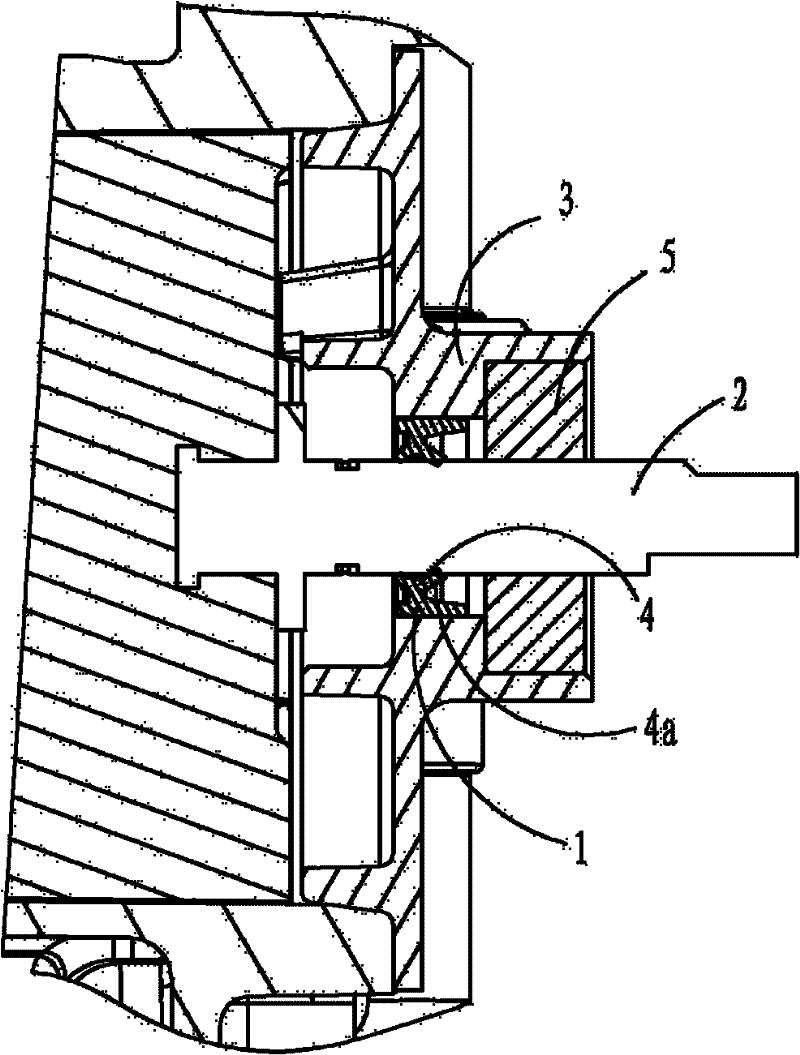

[0013] see figure 1 , the rotating shaft sealing structure in this embodiment is that the annular seal 1 is set between the inner hole of the rotating shaft 2 and the end cover 3, the rotating shaft 2 is positioned in the inner hole of the end cover 3 through the bearing 5, and the outer surface of the sealing member 1 The inner edge of the sealing member 1 is closely matched with the inner hole wall of the end cover 3, and the inner edge of the sealing member 1 is in conflict with the cylindrical surface of the rotating shaft 2 to prevent air leakage.

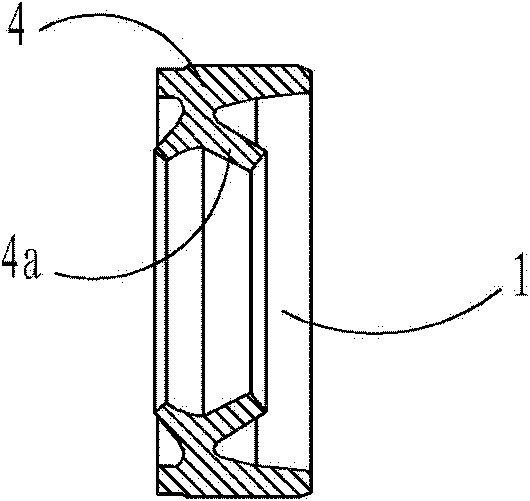

[0014] figure 1 , figure 2 As shown, in this embodiment, the cross-section of the sealing member 1 is set in a “K” shape, with one side of the flat surface of the “K”-shaped cross-section as the outer edge of the sealing member 1, and the other side of the “K”-shaped cross-section A pair of inclined-plane flanges 4 with a "eight" character on the sides is the inner edge of the sealing member 1, and the pair of inclined-plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com