Six-dimensional torque sensor acquisition system at the end of robot with automatic compensation and its zero drift compensation method and zero drift acquisition method

An automatic compensation and acquisition system technology, applied in the direction of instruments, manipulators, measuring forces, etc., can solve the problem of low accuracy of collected data, achieve the effect of improving accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

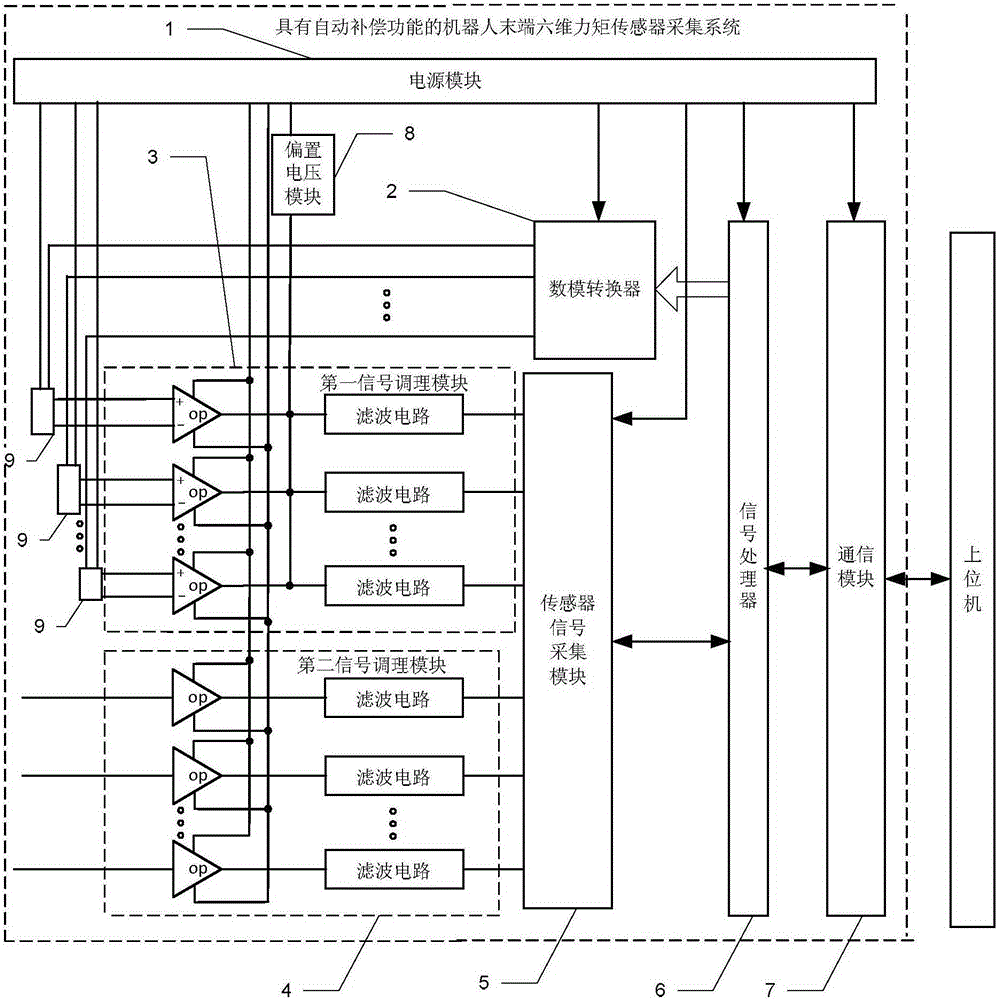

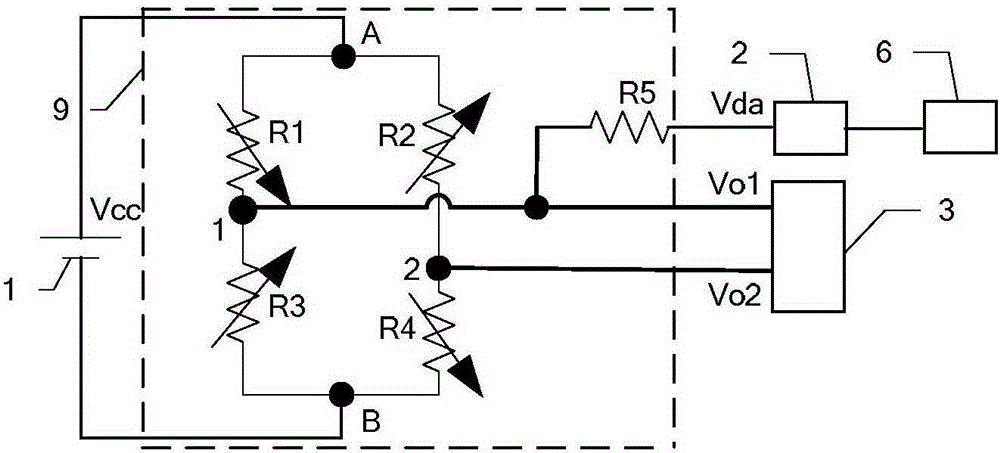

[0032] Specific implementation mode one: combine figure 1 Describe this embodiment, the six-dimensional torque sensor acquisition system at the end of the robot with automatic compensation described in this embodiment includes a torque signal input module 9, a digital-to-analog converter 2, a first signal conditioning module 3, and a second signal conditioning module 4. Sensor signal acquisition module 5, signal processor 6 and communication module 7;

[0033] The torque signal V output by 8 torque signal input modules 9 O1 respectively input to the 8 positive input terminals of the first signal conditioning module 3, and the torque signal V output by the 8 torque signal input module 9 O2 Input to the 8 reverse input terminals of the first signal conditioning module 3 respectively, the 8-way torque conditioning signals output by the first signal conditioning module 3 are input to the sensor signal acquisition module 5, and the collected 8-way temperature signals are input to ...

specific Embodiment approach 2

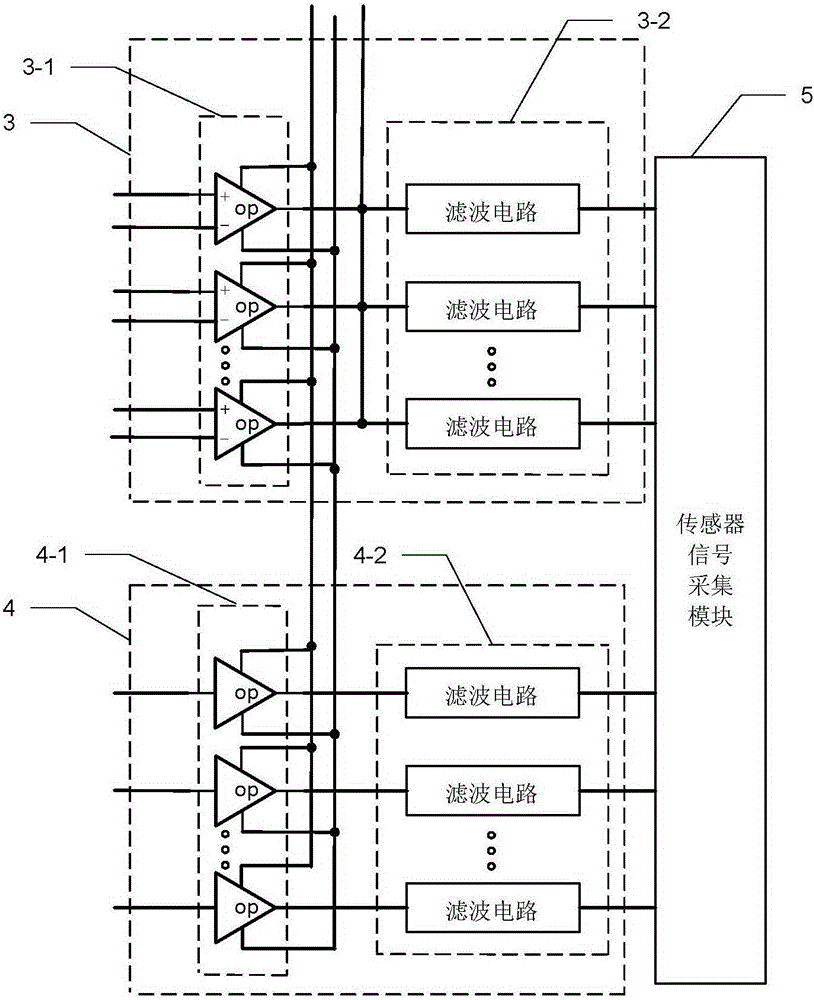

[0039] Specific implementation mode two: combination figure 2 This embodiment is described. This embodiment is a further limitation of the six-dimensional torque sensor acquisition system at the end of the robot with automatic compensation described in Embodiment 1. The first signal conditioning module 3 includes a first amplifier circuit module 3-1 and the first filtering circuit module 3-2;

[0040] The torque signals output by the 8 torque signal input modules 9 are respectively input to the eight signal input terminals of the first amplifying circuit module 3-1, and the 8-way amplified signals output by the first amplifying circuit module 3-1 are sent to the first filter circuit module Eight signal input terminals of 3-2, the first filter circuit module outputs 8 torque conditioning signals;

[0041] The second signal conditioning module 4 includes a second amplifying circuit module 4-1 and a second filtering circuit module 4-2;

[0042] The collected 8-way temperature ...

specific Embodiment approach 3

[0047] Embodiment 3: This embodiment is a further limitation of the six-dimensional torque sensor acquisition system at the end of the robot with automatic compensation described in Embodiment 1. Considering the requirements of overload protection, the first amplifying circuit module 3-1 and the second The amplification factor of the second amplification circuit module 4-1 meets the requirement of amplifying the range of the input analog signal to 0.5V-4.5V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com