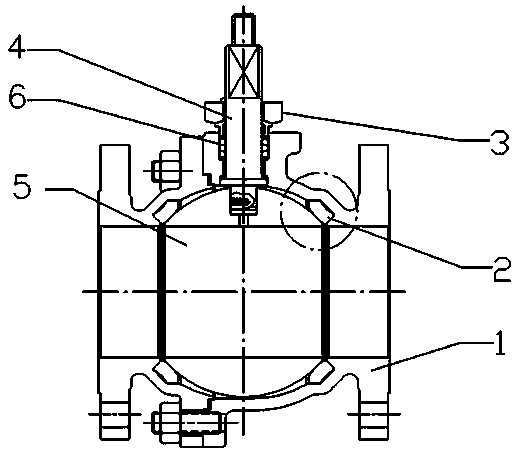

Self-compensating ball valve structure for seal wear

An automatic compensation and ball valve technology, applied in the direction of valve housing structure, shaft seal, valve details, etc., can solve the problems of valve leakage, short valve life, valve seat wear under pressure, etc., to achieve good compensation for valve seat wear and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In order to save money conveniently when the ball 5 or the valve stem 4 is damaged and needs to be replaced, the ball 5 and the valve stem 4 are detachably connected.

[0017] A sealing packing 6 is provided at the lower end of the bonnet 3, the junction of the valve stem 4 and the valve body 1 to ensure the sealing of the upper part of the valve, so that the overall sealing performance of the valve is better. The material of the sealing packing is PTFE, which has good elasticity and has Very good sealing performance.

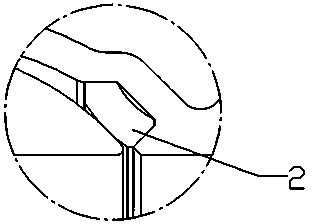

[0018] Valve seat 2 is made of PTFE material through special process, which has long-term plastic and elastic deformation. The surface of PTFE material has outstanding self-lubricating property, and almost all viscous substances cannot adhere to its surface; the valve body (1) Unique I-shaped design, after the ball 5 is assembled on the valve body 1, the compressed valve seat 2 enters the four corners of the I-shaped structure, and the valve seat 2 has g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com