Two-way non-reverse overrunning clutch

An overrunning clutch and non-return stop technology, applied to one-way clutches, clutches, mechanical equipment, etc., can solve the problems of inconvenient maintenance and short service life of two-way clutches, and achieve reliable operation, improved mechanical transmission efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

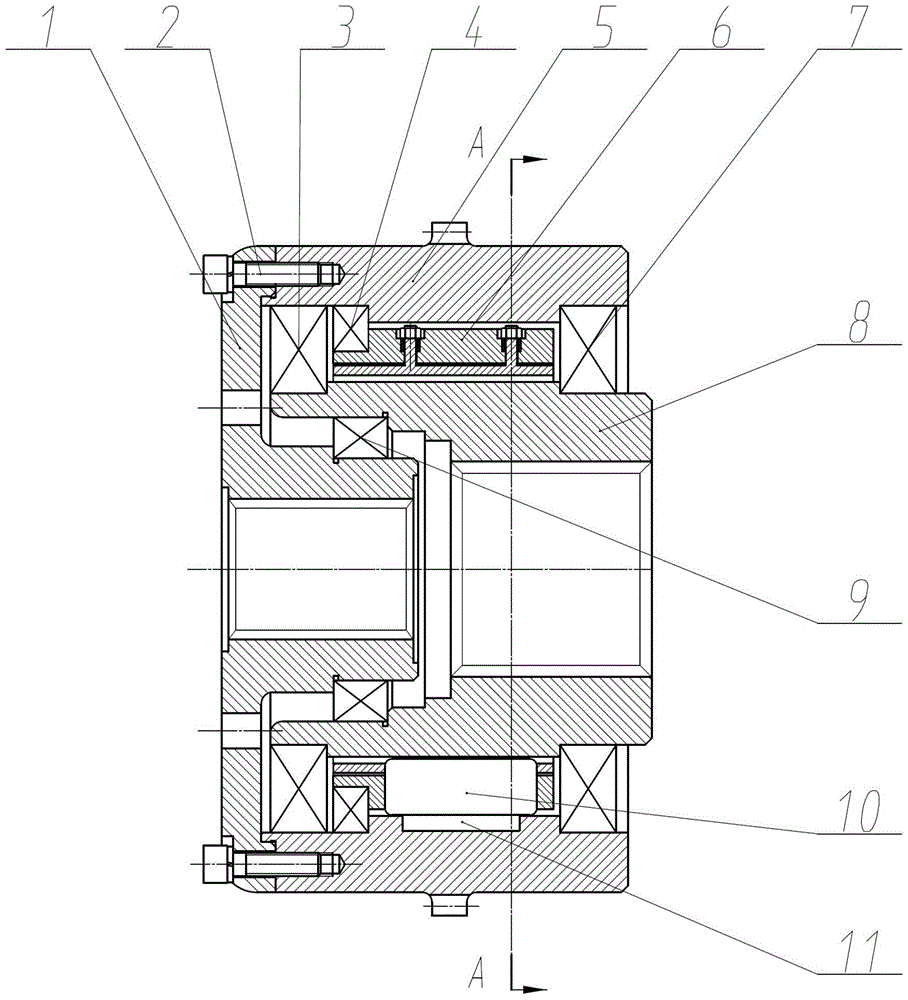

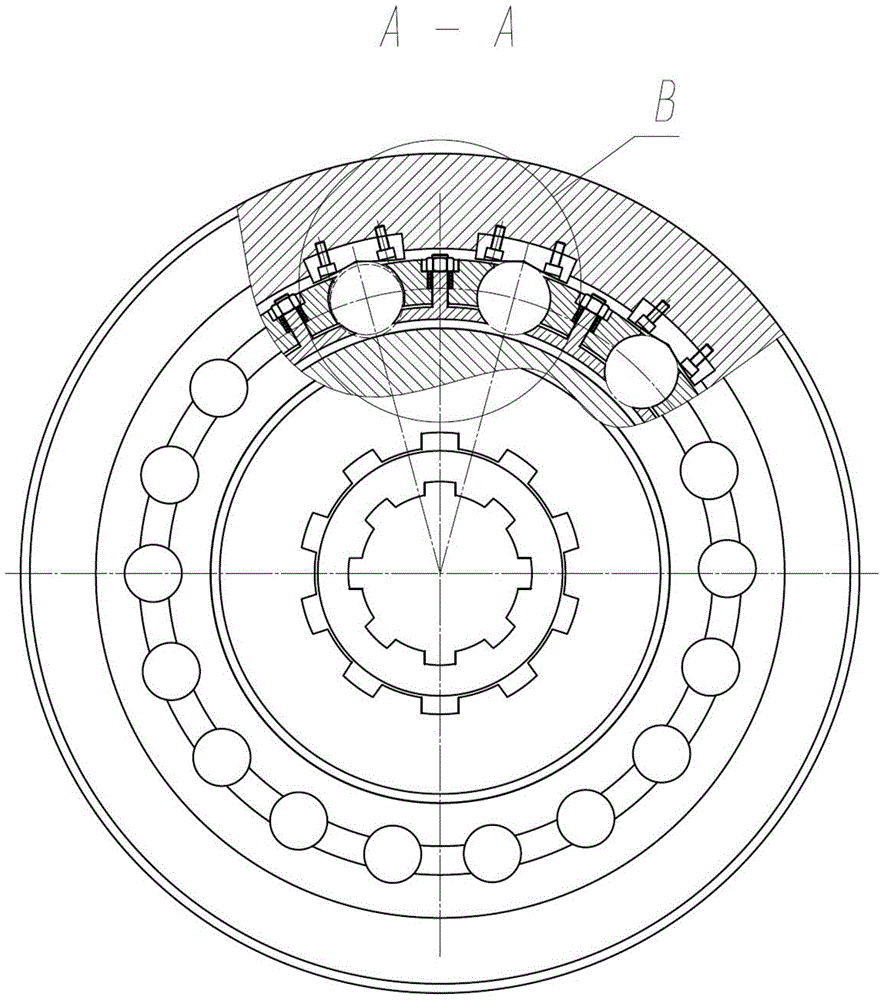

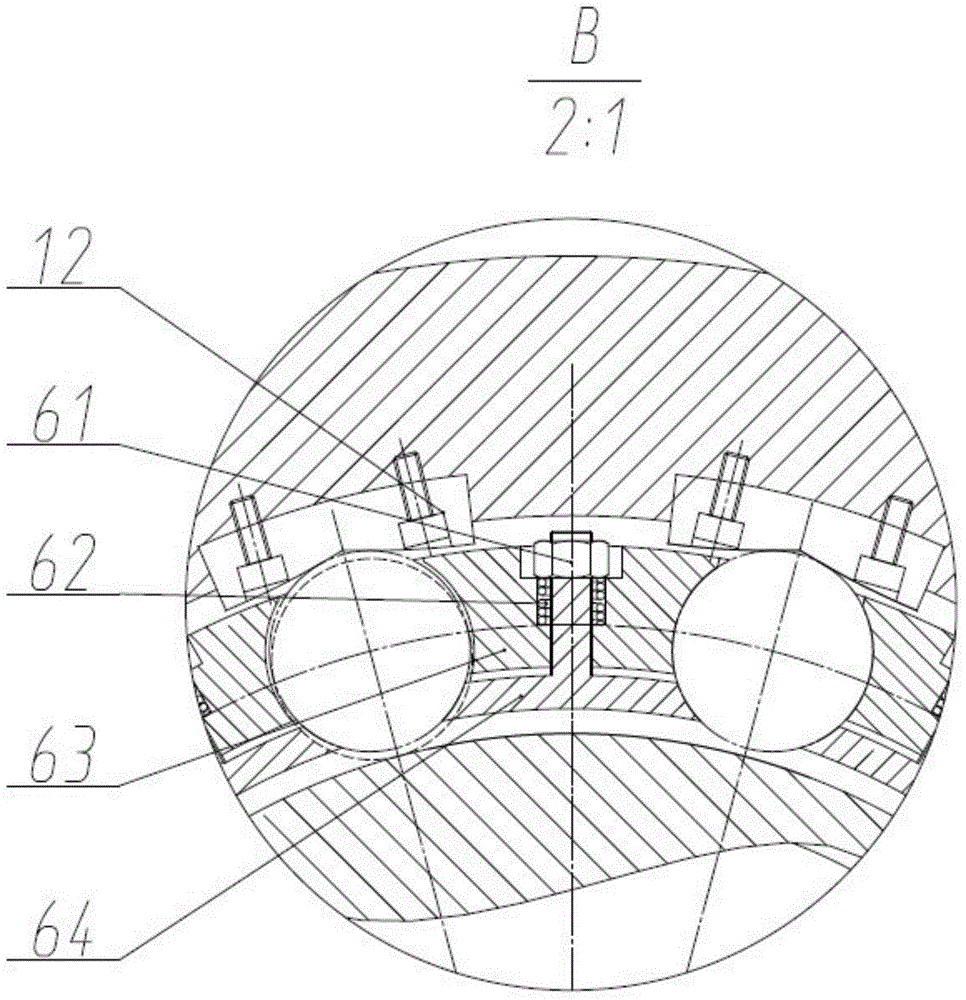

[0015] like Figure 1-3 As shown, the present invention will be further described through specific embodiments below.

[0016] A two-way non-reverse overrunning clutch, the lower cover plate 1 of the clutch is connected with the outer race 5 through the screw a2. The wedge block 11 is fixed on the outer race 5 by the screw b12. Furthermore, the outer race 5 and the cage outer ring 63 are coupled through the ball bearing b4. The rollers 10 are set in the roller grooves of the cage assembly 6, and two small shafts with thread protrude between every two roller grooves of the inner ring 64 of the cage, and the small shafts pass through the holes of the outer ring 63 of the cage. out. A spring 62 is sheathed on the small shaft, and the force of the spring 62 is adjusted by a nut 61 , so that the cage outer ring 63 and the cage inner ring 64 are close to each other. The inner race 8 is connected with the outer race 5 through two ball bearings a3 and b7, and there is a tapered ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com