Switching mechanism of truck steering-wheel horn

A switch mechanism and steering wheel technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve problems such as no sound of horns, reduced service life, poor contact, etc., and achieve the goals of improving product reliability, reducing production costs, and improving reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

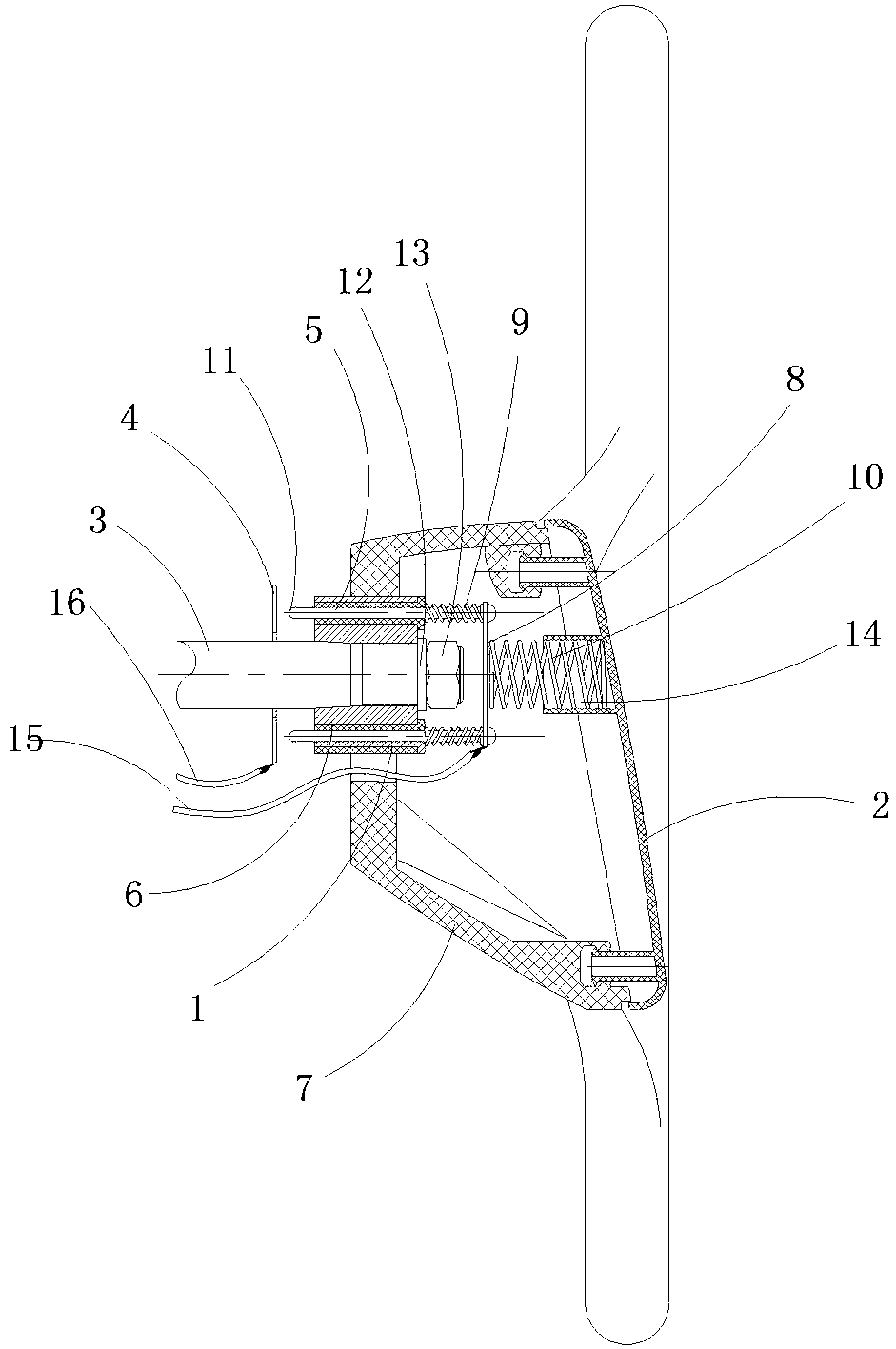

[0013] Embodiment 1: as figure 1 As shown, a truck steering wheel horn switch mechanism, including a steering wheel body 1, the steering wheel body 1 is provided with a horn cover 2, the steering wheel body 1 is provided with a switch mechanism, the switch mechanism includes a guide column 3. Friction plate 4, conductive rod 5, spline 6, insulating sleeve 7, connecting piece 8, conductive rod spring 9 and buffer spring 10, the guide column 3 is covered with a spline 6, and the spline 6 The outer jacket has an insulating sleeve 7, the insulating sleeve 7 is fixed with the steering wheel main body 1, the conductive rod 5 is inserted into the connecting piece 8, the conductive rod 5 is covered with a conductive rod spring 9, and the conductive rod 5 Inserted into the insulating sleeve 7, the friction plate 4 is socketed with the guide column 3, the friction plate 4 is located below the spline 6, and the conductive contact 11 at the bottom of the conductive rod 5 is in contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com