Method and apparatus for production of helical springs by spring winding

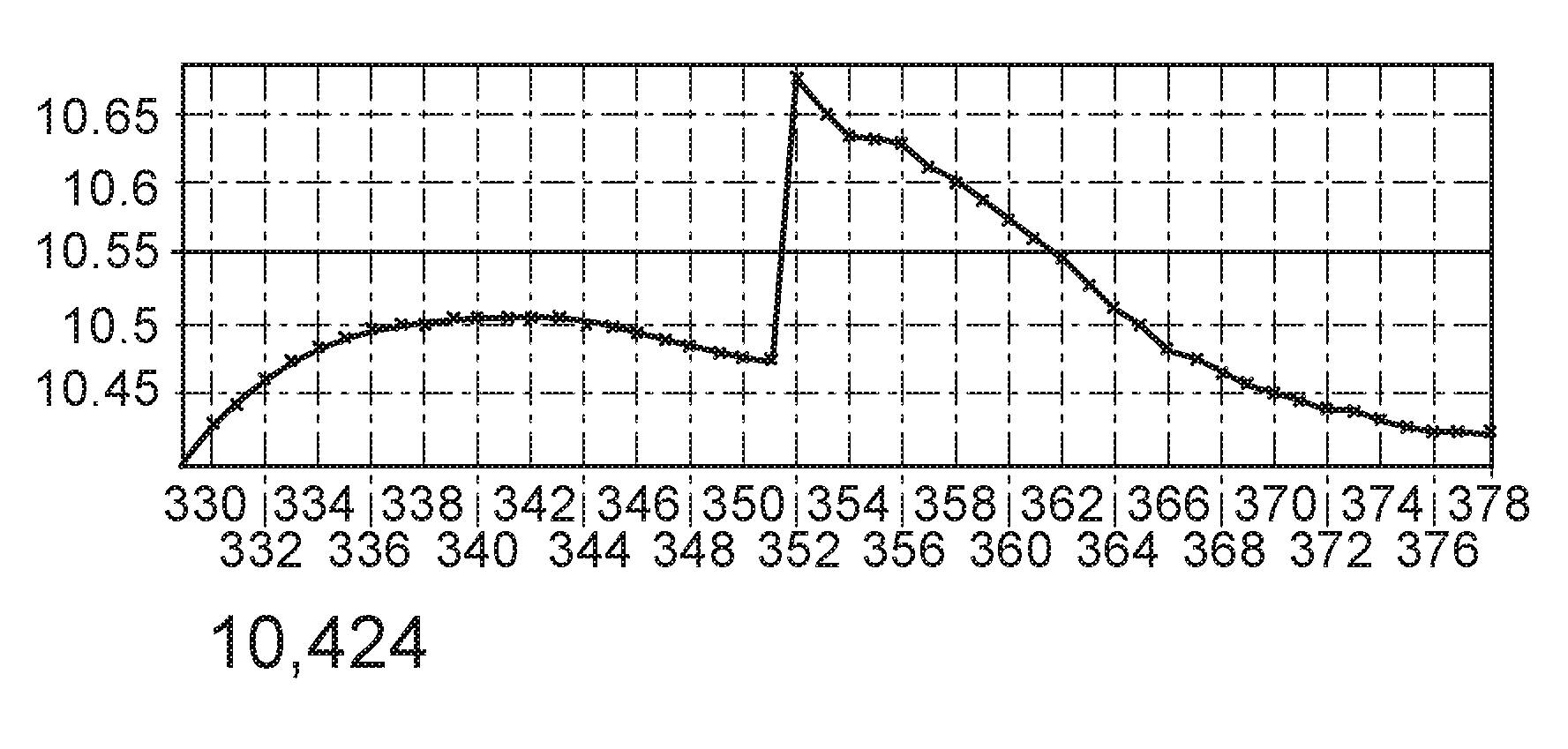

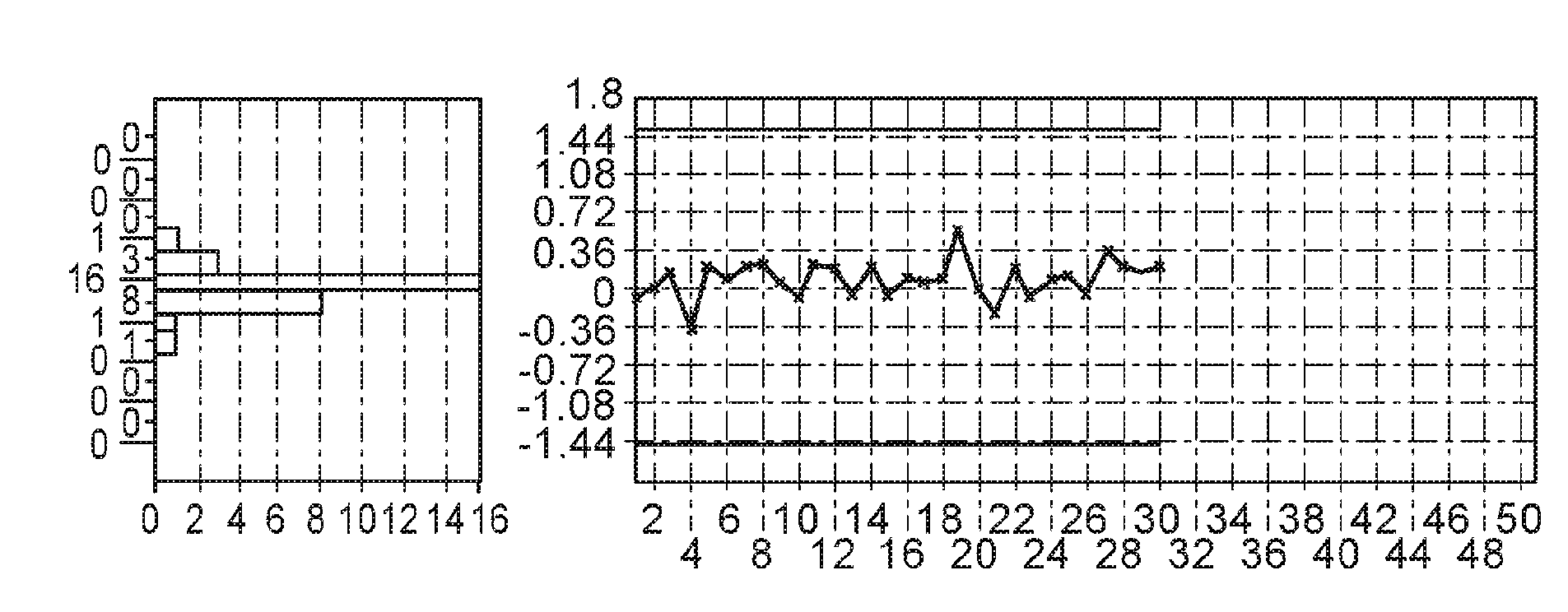

A technology of coil spring and coil spring, applied in the field of coil spring machine, can solve problems such as uneconomical, and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

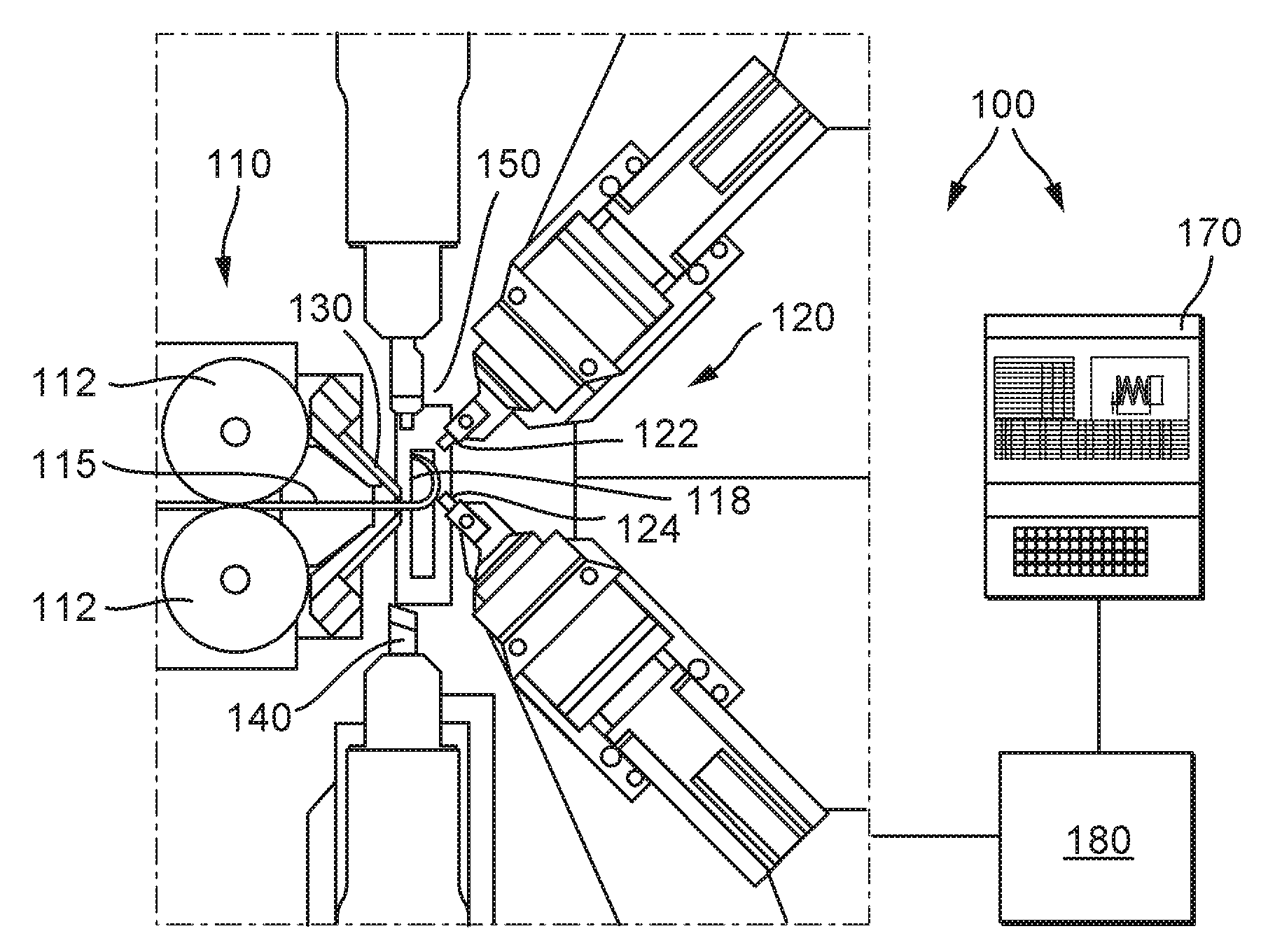

[0045] exist figure 1 The schematic diagram in shows the main elements of a CNC spring winding machine 100 based on a design known per se. The spring coiler 100 has a conveying device 110 which is equipped with conveying rollers 112 and which conveys a continuous wire section of wire 115 which comes from a wire supply and passes through a guide unit at a digitally controlled conveying rate The curve enters into the region of the shaping device 120 . With the help of digitally controlled tools, the wire is shaped in a forming device to form a helical spring. The tool comprises two winding pins 122 , 124 arranged offset at an angle of 90° and radially aligned with respect to the central axis 118 (position corresponding to the desired spring axis) and intended to determine the diameter of the helical spring. During the setting process, the position of the winding pin can be changed for the basic adjustment of the spring diameter along the line of motion shown in dashed lines an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com