Air cylinder of piston type compressor

A compressor and piston-type technology, applied in the field of piston-type gas compressors, can solve problems such as increased design costs, troublesome processing and manufacturing, and disadvantages, and achieve the effects of simplifying design and production, reducing production costs, and reducing cylinder series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

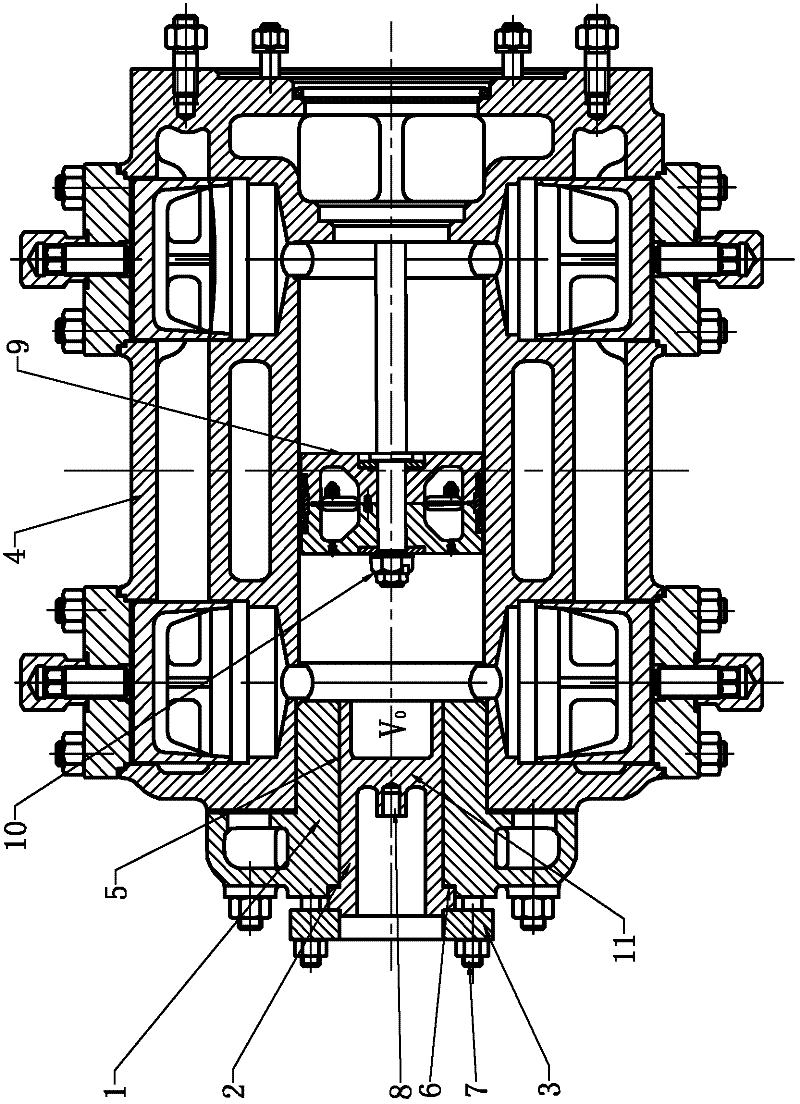

[0027] Such as figure 1 As shown, a piston compressor cylinder of the present invention, the cylinder head 1 is installed on one end of the cylinder block 4, the cylinder head 1 is provided with a circular through hole 5 leading into the cylinder block 4; the material of the clearance adjustment cover 2 It is cast iron, in order to save costs, its longitudinal cross-sectional shape is similar to the horizontal H-shape, installed in the through hole 5, and closely fitted with the inner wall of the through hole 5; the clearance adjustment cover 2 is opposite to the outer end surface of the cylinder head 1. A sealing washer 6 is provided at the contact position. The outer end surface of the clearance adjustment cover 2 is provided with an annular groove at the outer circumferential position. The gland 3 is a circular ring steel plate. The inner circular end surface of the gland 3 is clamped at the annular groove, and the gland 3 is Four fixing bolts are installed evenly along the c...

Embodiment 2

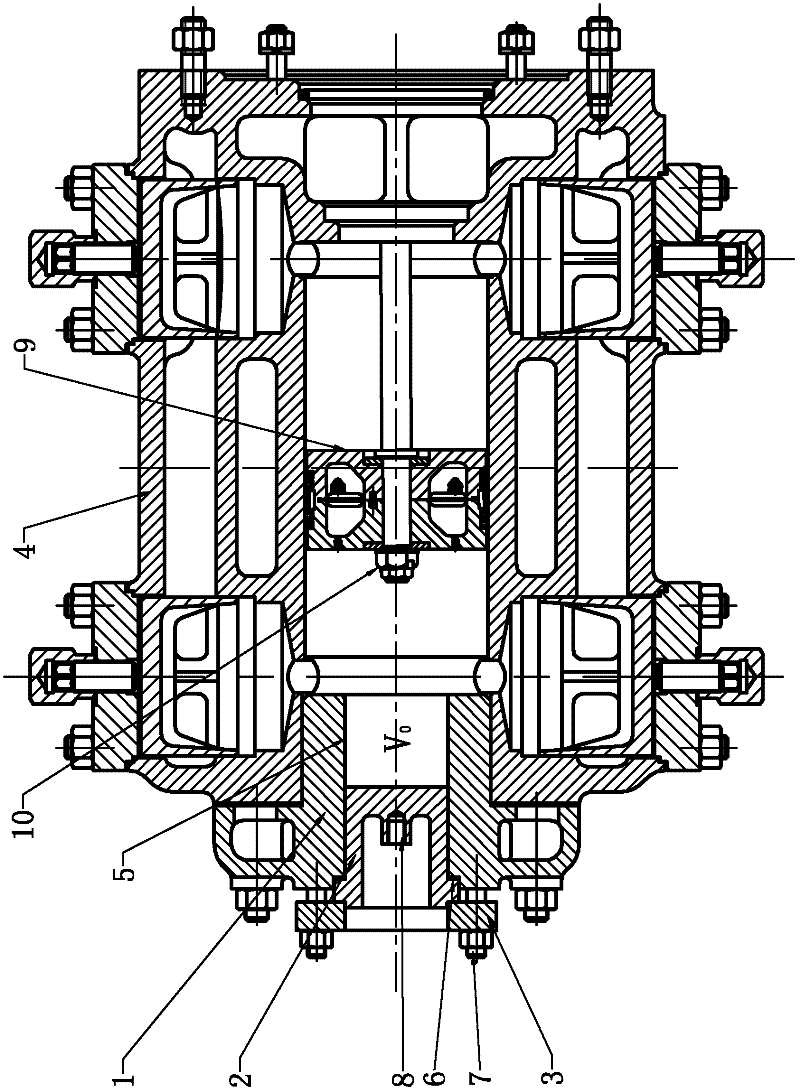

[0030] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is only: the longitudinal cross-sectional shape of the clearance adjustment cover 2 is similar to a flat U-shape, the U-shaped opening points out of the cylinder 4, and the piston 9 moves to the top dead center. The clearance volume V of the cylinder block 4 side in the hour through hole 5 0 It is larger than the inherent clearance volume of the cylinder; the clearance adjustment cover 2 in this embodiment is different according to the depth of the U-shaped sealing port extending into the through hole 5, and different models are available to adapt to different clearance adjustment needs . The clearance volume V in this embodiment 0 The clearance volume is larger than that in the first embodiment, so the displacement Vm of the compressor cylinder will have different reductions according to different clearance adjustment cover models, which can satisfy different discharges on the bas...

Embodiment 3

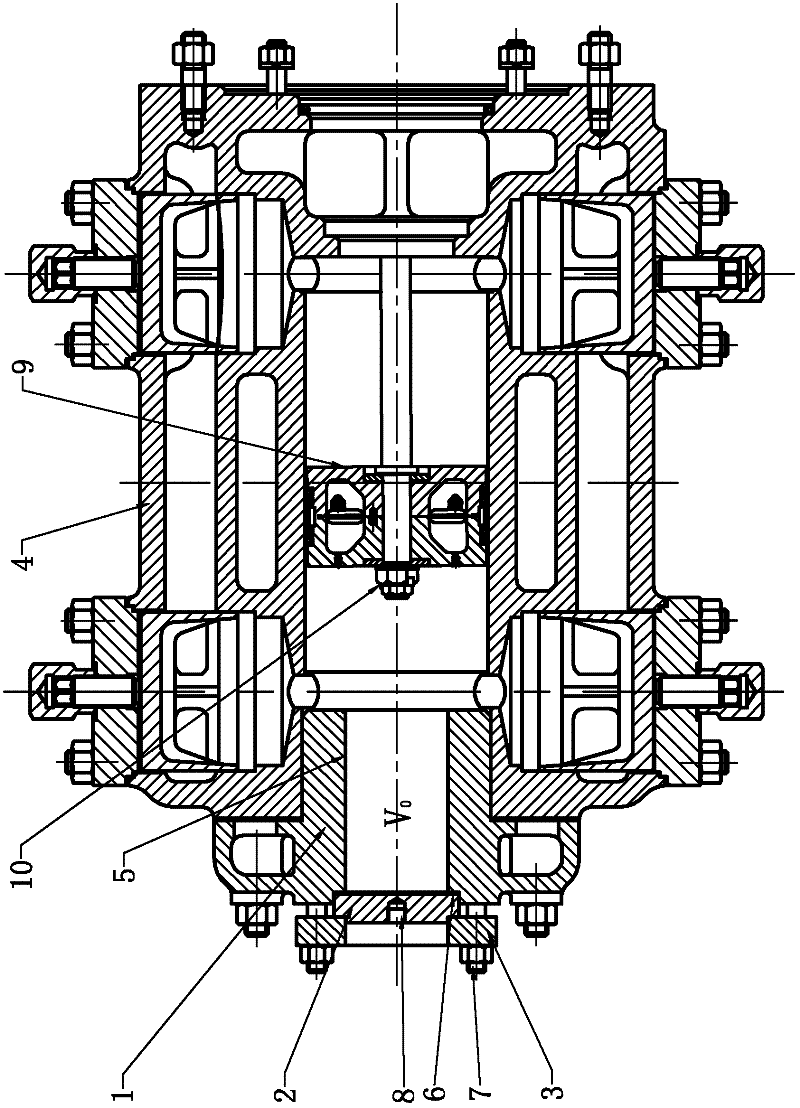

[0032] Such as image 3 As shown, the difference between this embodiment and the first embodiment is only: the clearance adjustment cover 2 is a plate-shaped structure, and is installed at the outer port of the through hole 5, and the axial position of the clearance adjustment cover 2 is not provided with a protrusion. The screw hole 8 is directly opened on the clearance adjustment cover; the material of the clearance adjustment cover is steel; the clearance volume V at this time 0 The maximum, that is, the reduction in the displacement of the compressor is the largest, so the displacement Vm of the compressor is the smallest relative to the first and second embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com