Cross type efficient reinforced braking method

A cross-type, high-efficiency technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve problems such as unsatisfactory effects, high pull-in voltage, large pull-in current, etc., and achieve low pull-in voltage , small pull-in current, large braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

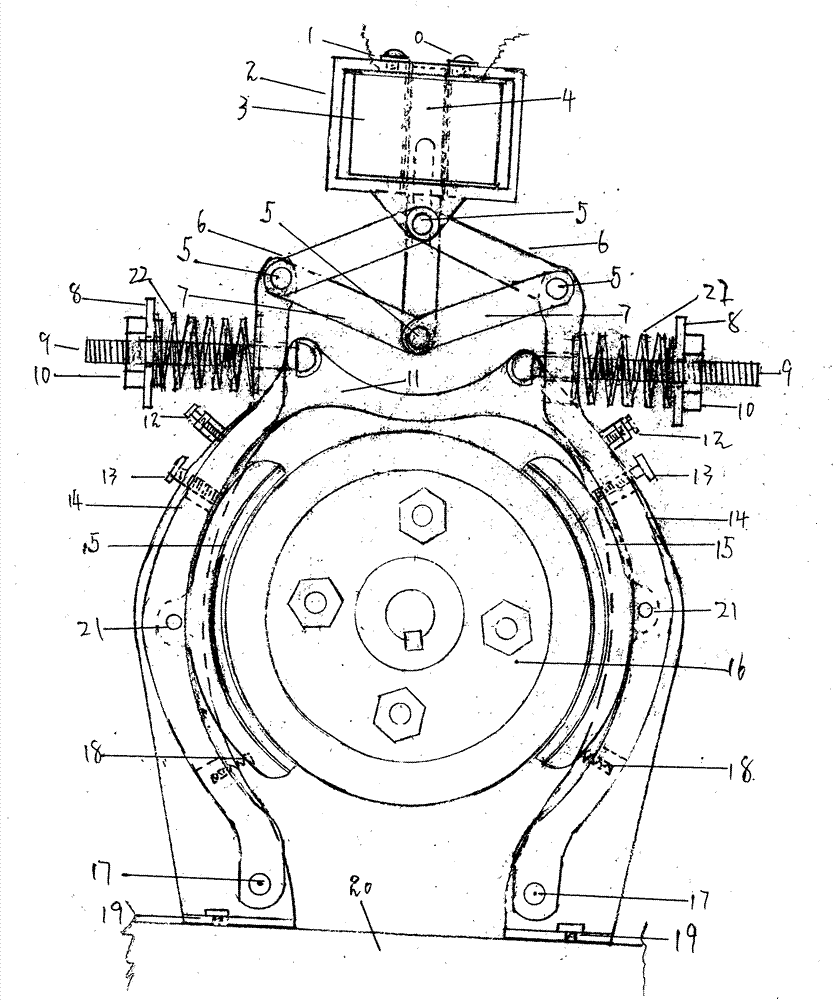

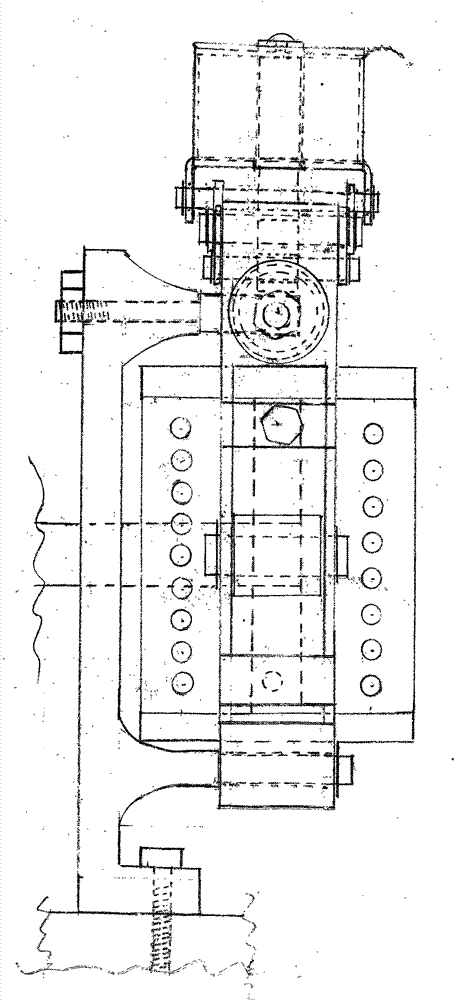

[0024] Put the connecting shaft 5 in the pair of perforations on the front and rear planes near the top of the left and right brake frames 14, and then stack the front and rear planes of the two support plates 6 so that the center points of the pair of perforations at one end of the plane are aligned before and after aligning with each other. After the connecting shaft 5 that has been put on earlier on the front and rear planes of the brake frame 14 upper ends is put on, put jump ring in the circular groove on the arc surface of the two near tops of the connecting shaft 5 .

[0025] Put the end of the round hole on the front and rear planes of the suction iron core 4 downwards, and insert the inner planes of the front and back planes and the superimposed support plate 6 that has been placed on the upper ends of the left and right brake frames 14 into its space correspondingly, so that the left side brake The other end of that piece of support plate 6 close to its plane on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com