Disc brake braking mine car

A technology for disc brakes and mine cars, which is applied to brakes with brakes, pneumatic brakes, operating mechanisms of railway vehicle brakes, etc. , to achieve the effect of large braking force, ensuring no slippage and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

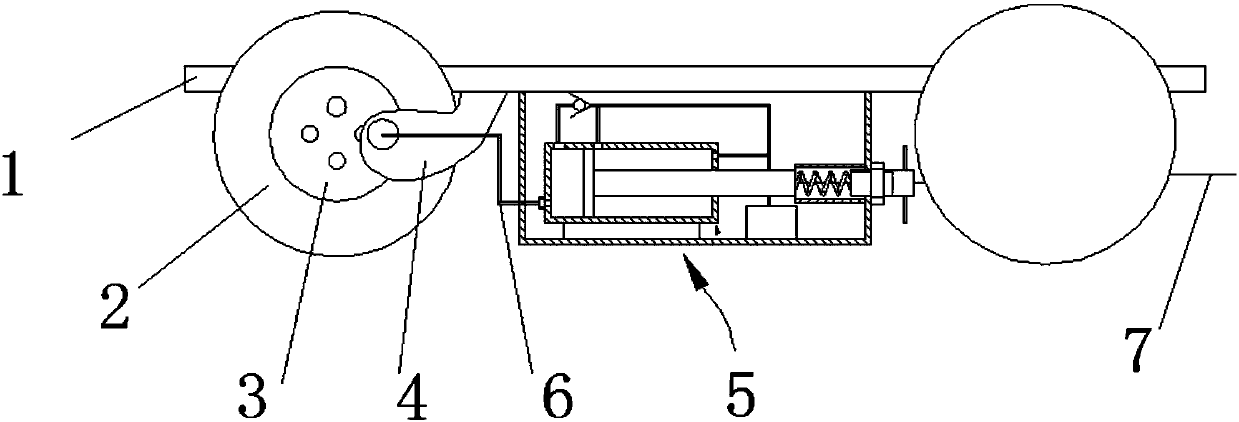

[0016] Such as Figure 1 to Figure 3 As shown, a mine car with disc brakes of the present invention includes a mine car body 1 and wheels 2, the mine car body 1 is connected with a disc brake caliper 4 and a disc brake control device 5, and the wheels 2 Disk 3 is connected;

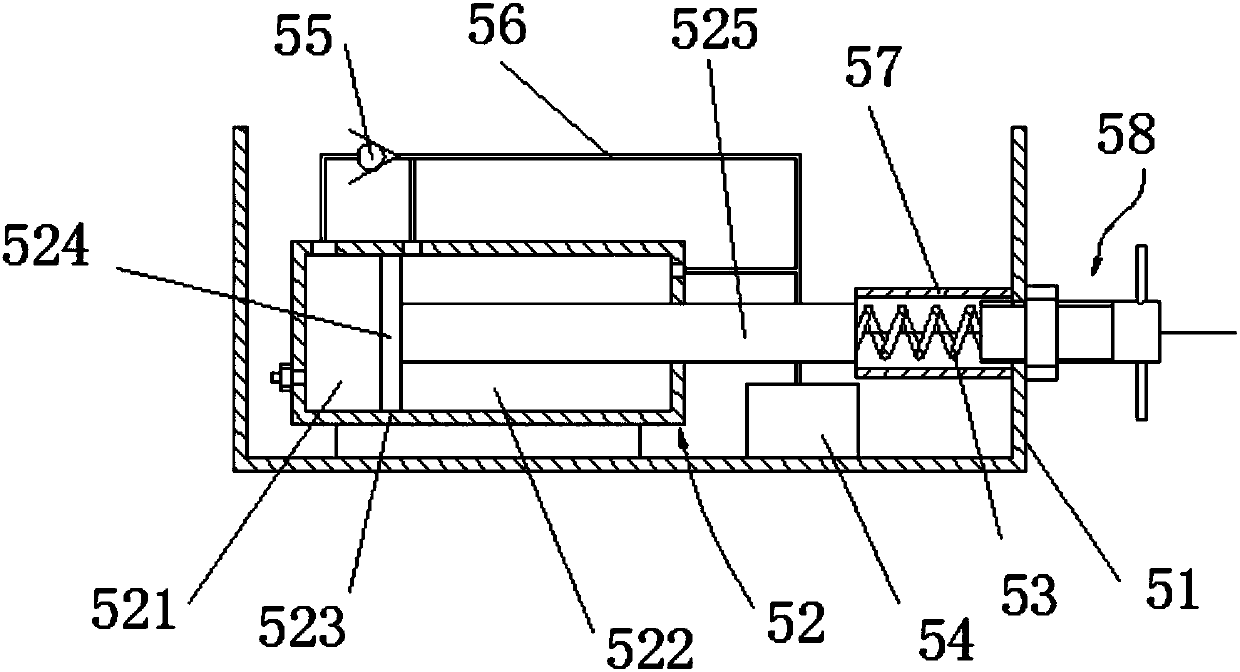

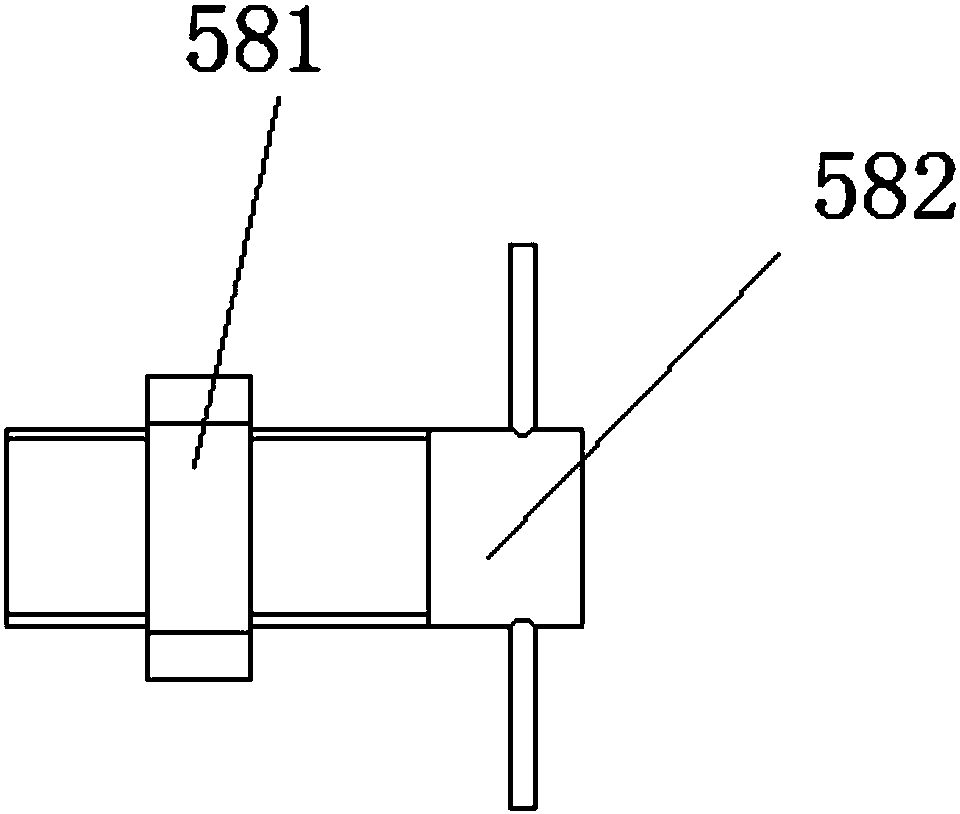

[0017] The disc brake control device 5 includes a mounting frame 51, a hydraulic cylinder 52, a spring 53, and an oil storage tank 54; The rod 525 is connected, and the other end is connected with the mounting frame 51; the chamber 2 522 of the hydraulic cylinder 52 is connected with the oil return channel 56 that the piston 523 of the hydraulic cylinder 52 moves, and the oil return channel 56 communicates with the oil storage tank 54; The chamber one 521 of the hydraulic cylinder 52 communicates with the oil storage tank 54 and is provided with a check valve 55 that only allows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com