Automatic adjusting arm of automobile braking system

An automobile brake system and automatic arm adjustment technology, applied in the direction of slack adjuster, etc., can solve the problems of reduced braking force, increased gap between brake drum and shoe, decreased thrust of brake air chamber, etc., to achieve shortened braking Effects of reaction time, shortened braking distance, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

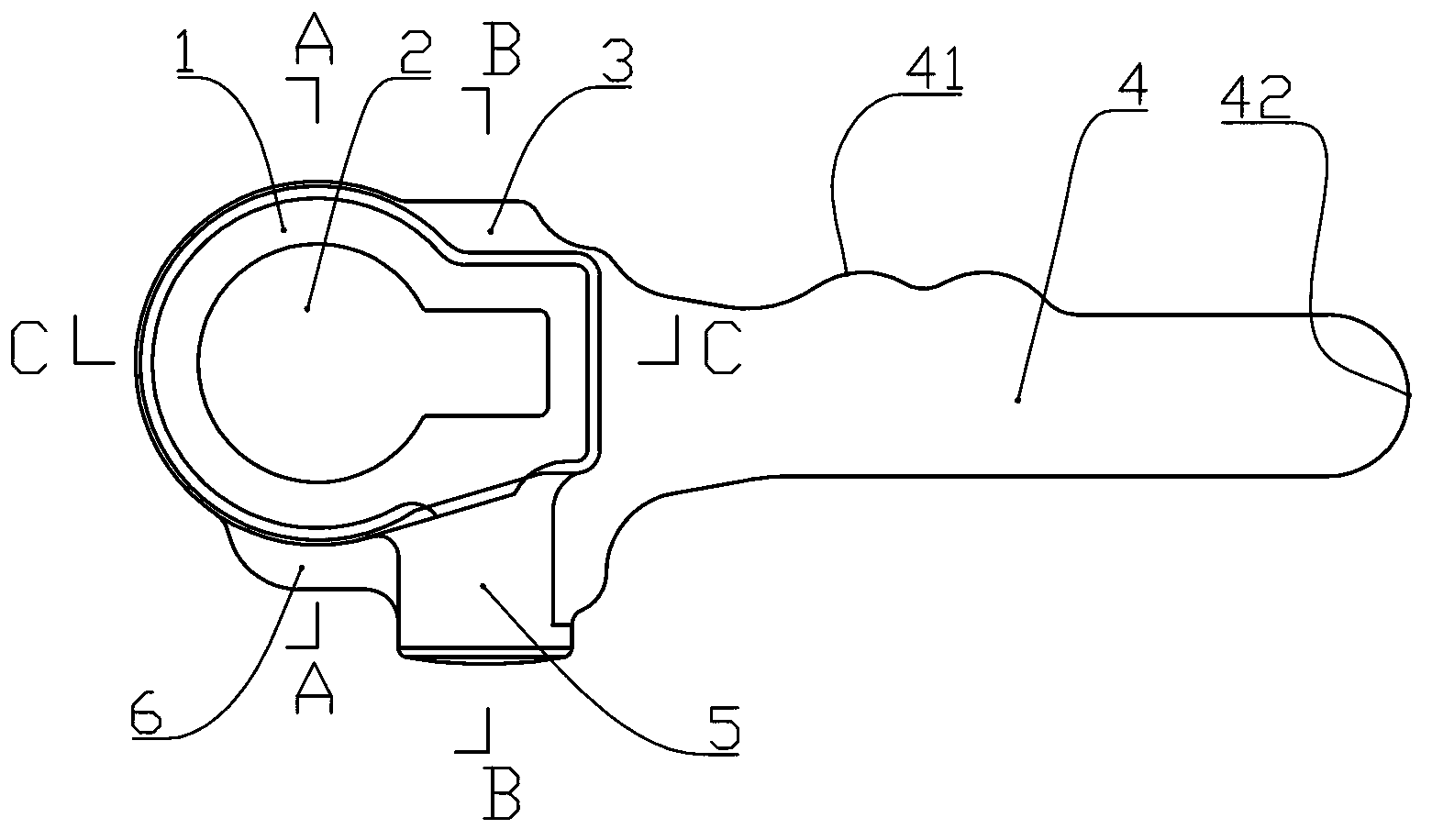

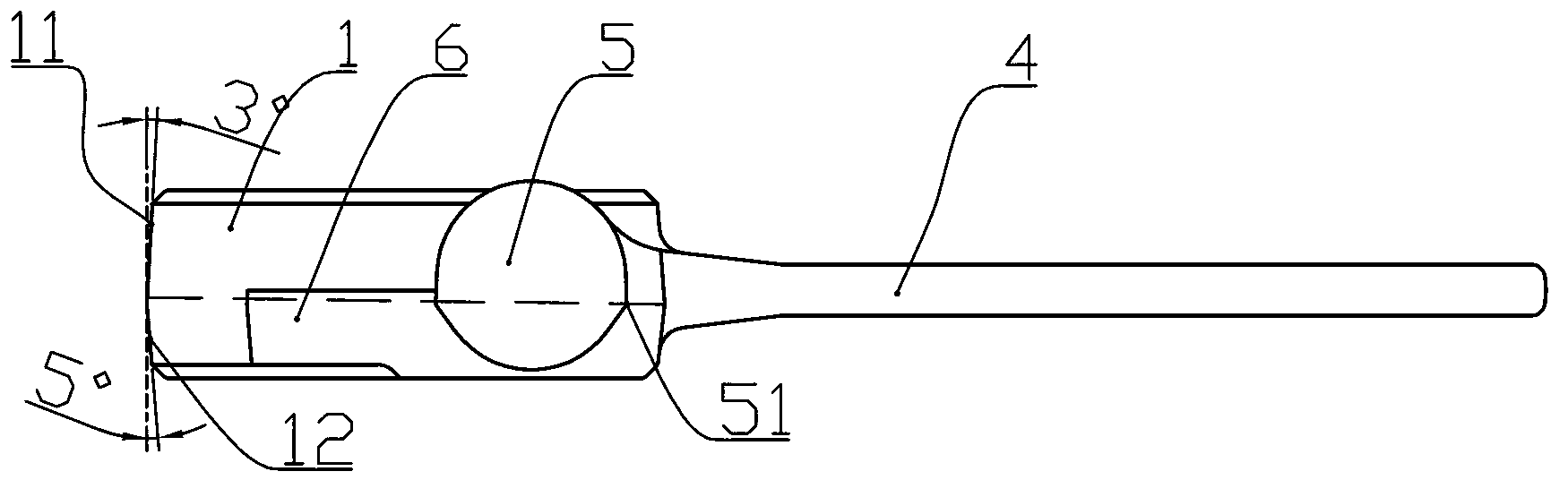

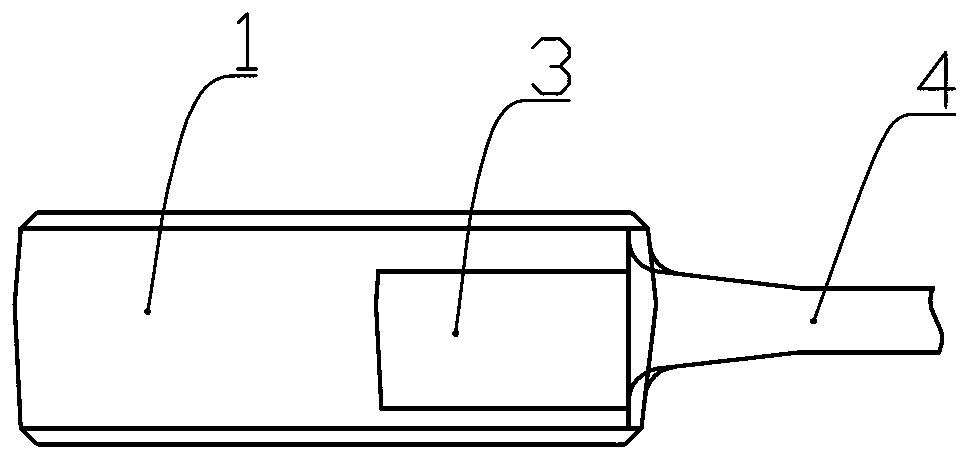

[0015] according to Figure 1 to Figure 7 As shown, the automatic adjustment arm of an automobile braking system described in this embodiment includes a swing arm 4, one end of the swing arm 4 is connected with a control wheel connection part 1, and a connection hole 2 is provided on the control wheel connection part 1, and the connection The hole 2 is composed of a circular hole and a rectangular hole located on the side of the circular hole close to the swing arm 4. The shape of the outer peripheral end surface of the control wheel connecting part 1 is the same as that of the connecting hole 2, and the connecting hole 2 includes a middle in the axial direction. The column hole 22 and the tapered hole 21 which is wide on the outside and narrow on the inside are located at the upper and lower ends of the column hole 22 respectively; an ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com