Lever type puller

A lever-type and connecting-rod technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of easily shaking hands, not being suitable for complex external environments, and not being able to use force, etc., to increase the number of applicable occasions, the structure is simple and reasonable, The effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

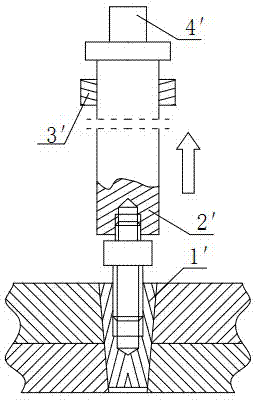

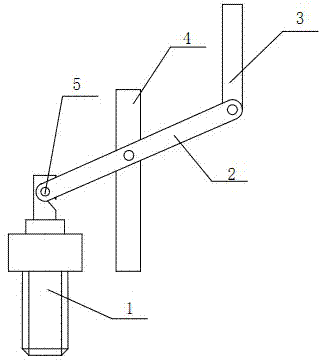

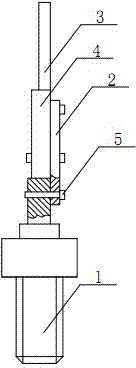

[0024] Reference Figure 2-4 , The lever type horse puller includes a threaded head 1. The threaded head 1 is a stepped round shaft structure, one end of which is an external thread structure for connecting a shaft pin, and an oblique opening slot 11 is provided on the other end. A living hinge 5 is installed in the opening slot 11, and a connecting rod 2 is connected to the living hinge 5, the other end of the connecting rod 2 is hinged with a booster rod 3, and the middle of the connecting rod 2 is hinged with a supporting rod 4, The threaded head 1, the support rod 4, and the force rod 3 are parallel to each other.

[0025] The connecting rod 2 is a cylindrical rod, which is connected to the supporting rod 4 and the booster rod 3 through living hinges.

[0026] The principle of the present invention is basically the same as the principle of lever. The supporting rod 4 on the connecting rod 2 can be regarded as a fulcrum, and the connecting rod 2 can be regarded as a lever. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com