Stove burner

A technology of burners and burner caps, applied in the direction of burners, gas fuel burners, combustion methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

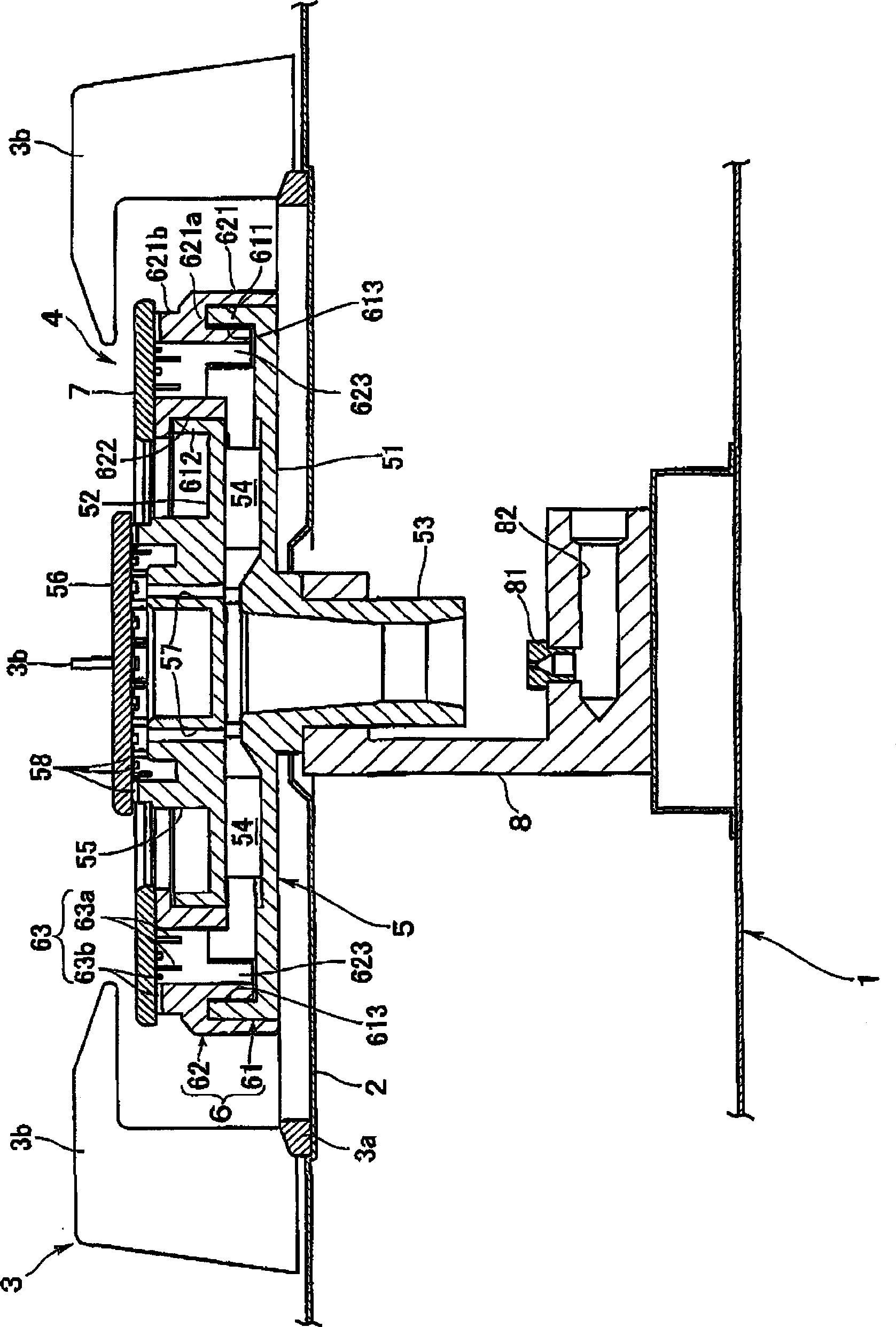

[0017] refer to figure 1 , 1 denotes the main body of the stove, and 2 denotes a panel covering the upper surface of the main body 1 of the stove. The fire support 3 is placed on the panel 2, and the burner 4 for stoves 4 which concerns on embodiment of this invention is installed in the part surrounded by the fire support 3. In addition, the fire stay 3 is formed by attaching a plurality of (for example, four) fire stay claws 3b to an annular fire stay frame 3a seated on the panel 2 so that there are intervals in the circumferential direction. .

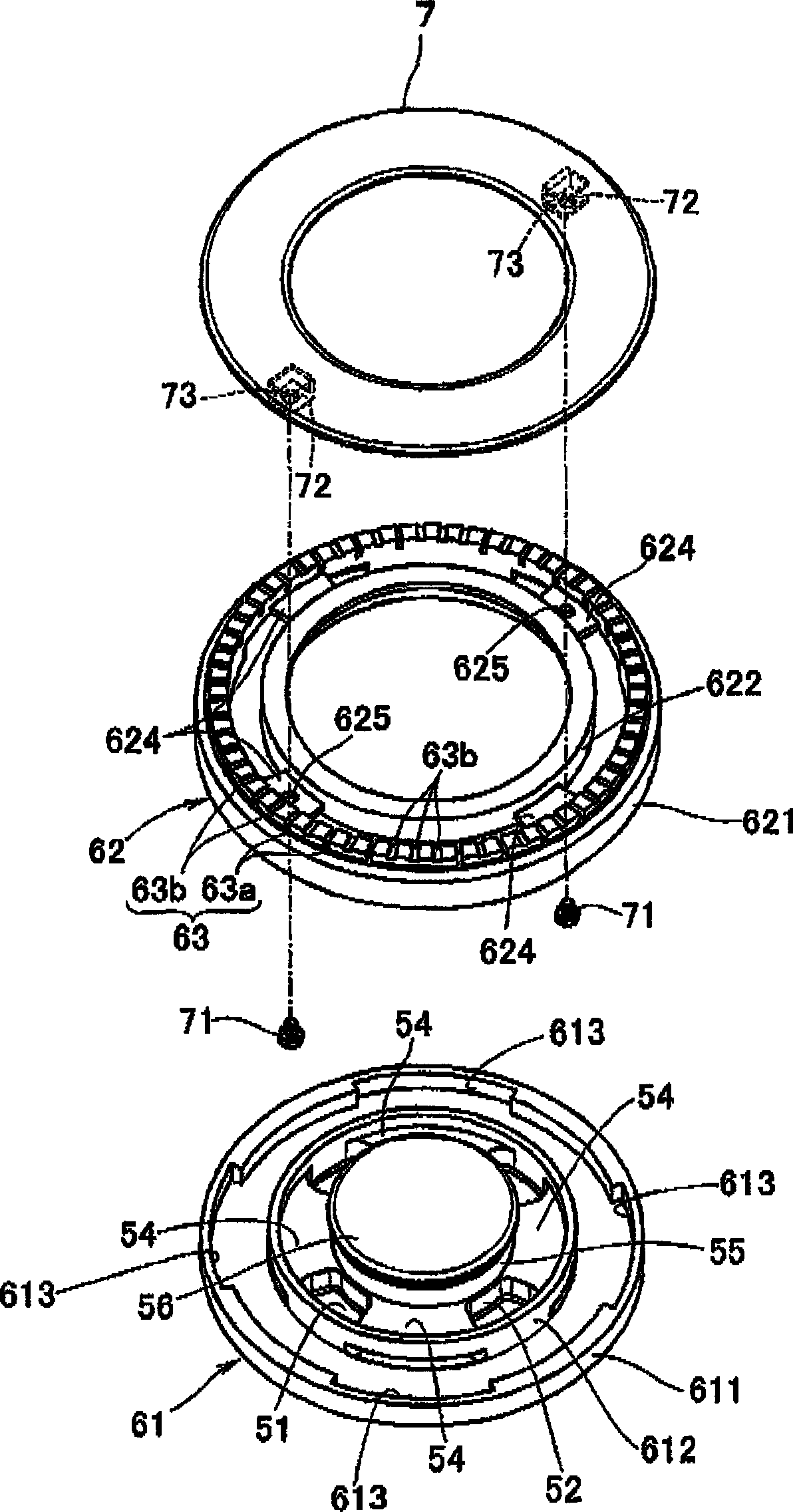

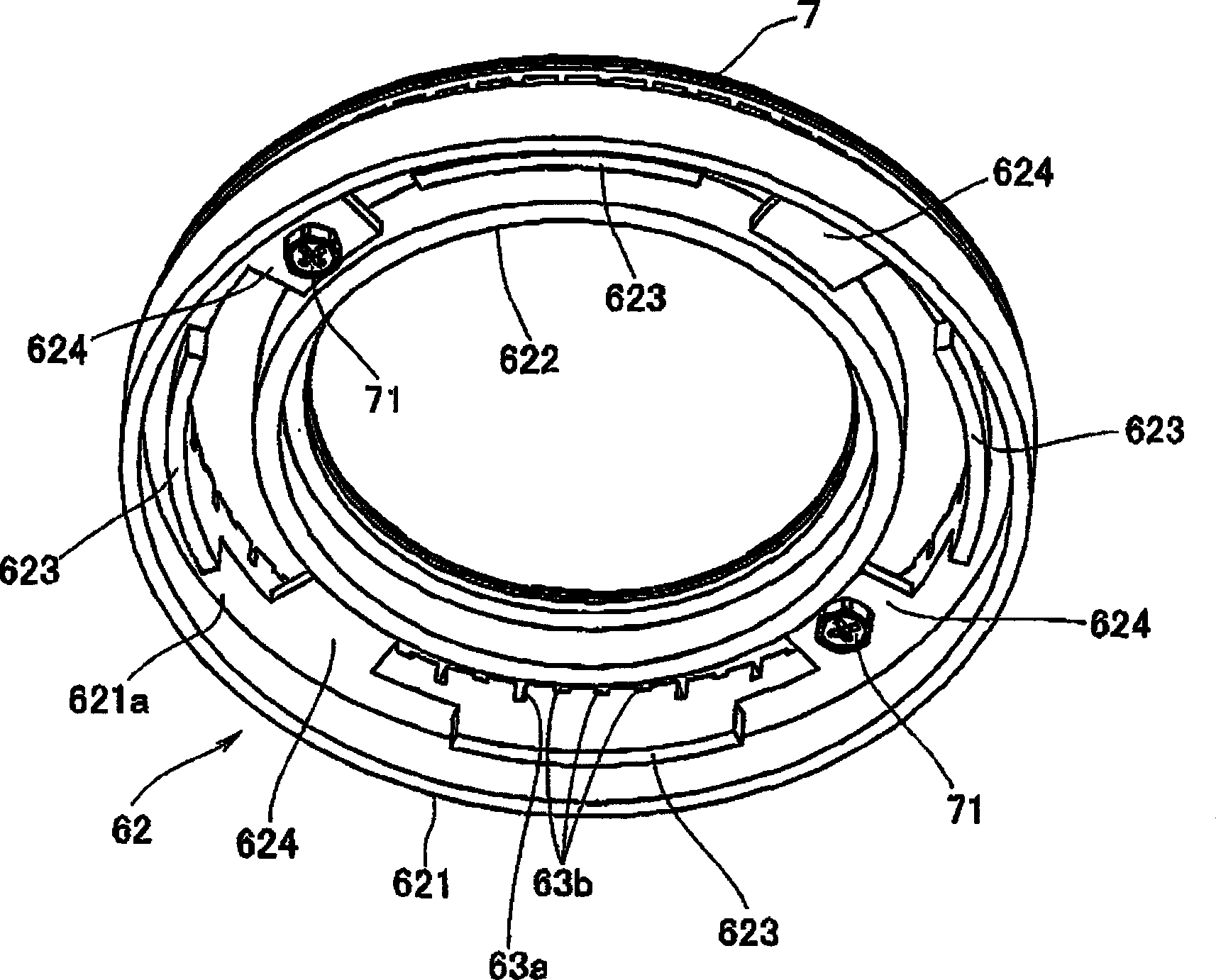

[0018] The burner 4 for a stove includes a burner body 5 having a ring-shaped burner head 6 opening upward, and a burner cap 7 provided on the burner head 6 . In addition, the burner head 6 is divided into two parts, a lower burner head 61 and an upper burner head 62 .

[0019] The burner body 5 has a lower plate portion 51 supported by a support block 8 provided in the furnace body 1 , and an upper plate portion 52 having a smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com