Sealing Improvement Structure of Top-mounted Air Filter

An air filter and filter housing technology, applied in the directions of dispersed particle filtration, chemical instruments and methods, separation methods, etc., can solve the problems of air leakage, difficulty in achieving sufficient sealing effect, affecting the effect of air filters, etc., and achieve easy disassembly. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

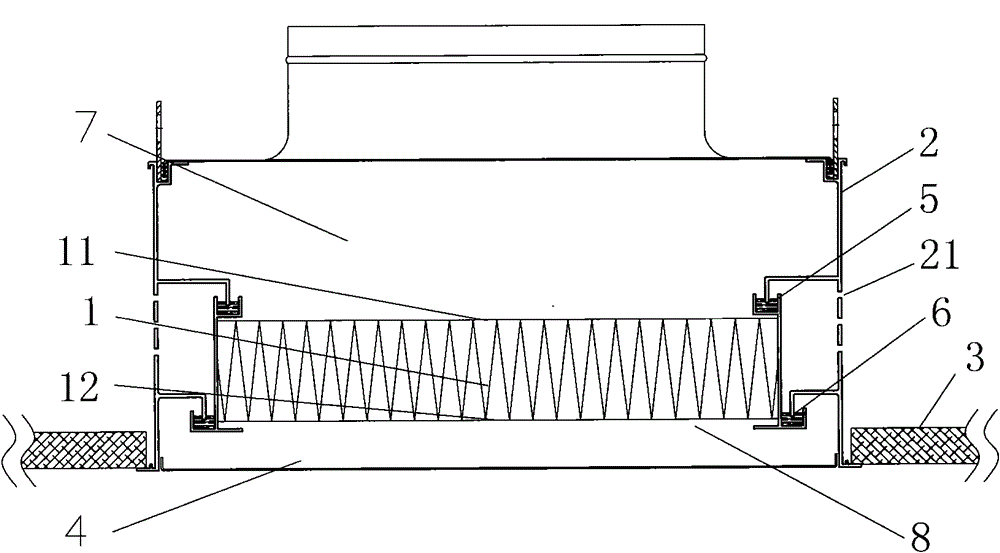

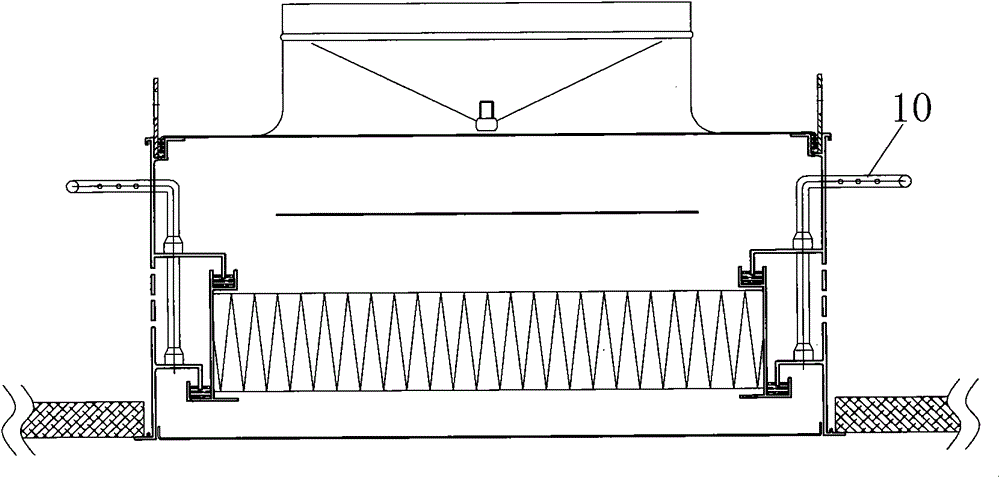

[0010] Embodiment: an improved sealing structure of a top-mounted air filter, the sealing structure of the air filter 1 includes an air filter 1 and a filter housing 2, based on the installation and use direction, the upper end of the air filter 1 is The air inlet 11, the lower end of the air filter 1 is an air outlet 12, the air filter 1 is detachably fixed in the filter housing 2, the filter housing 2 is fixed on the top plate 3 of the box, the filter housing 2 The upper end is connected to the ventilation equipment, the lower end of the filter housing 2 is connected to the ventilation hole 4 of the box body, and a first sealing device 5 is provided between the inner side of the filter housing 2 and the outer side of the air filter 1 to divide the filter housing 2 into a high-pressure air inlet area 7 and the low-pressure air outlet area 8, the high-pressure air inlet area 7 is connected to the ventilation equipment and the air inlet of the air filter 1 at the same time, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap