Telegraph pole crusher

A technology of utility poles and pulverizers, applied in grain processing, etc., can solve the problems of waste of storage, occupation of manpower, and delay of work deadlines, etc., and achieve the effect of simple design structure, reduced labor intensity, and saved floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

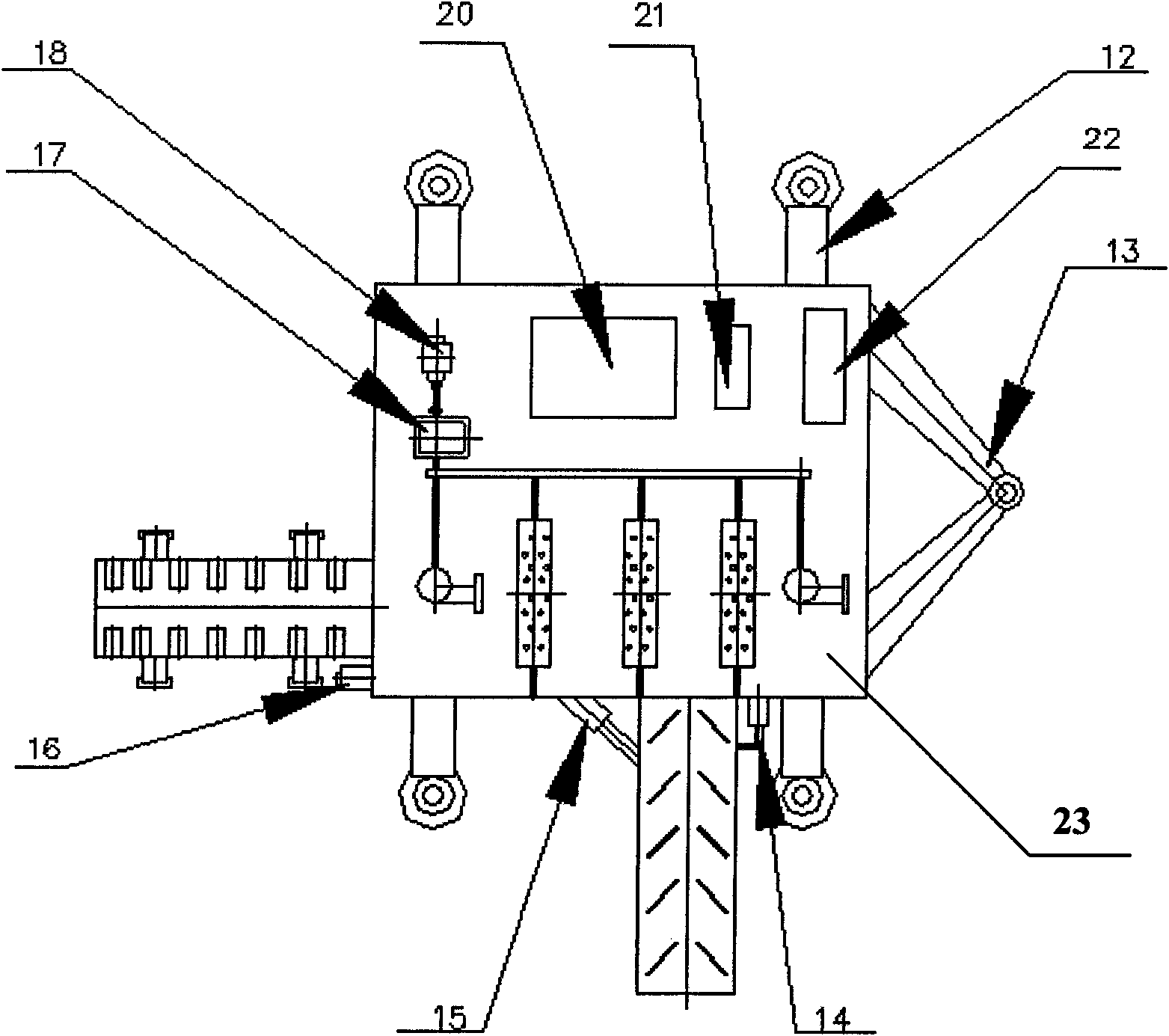

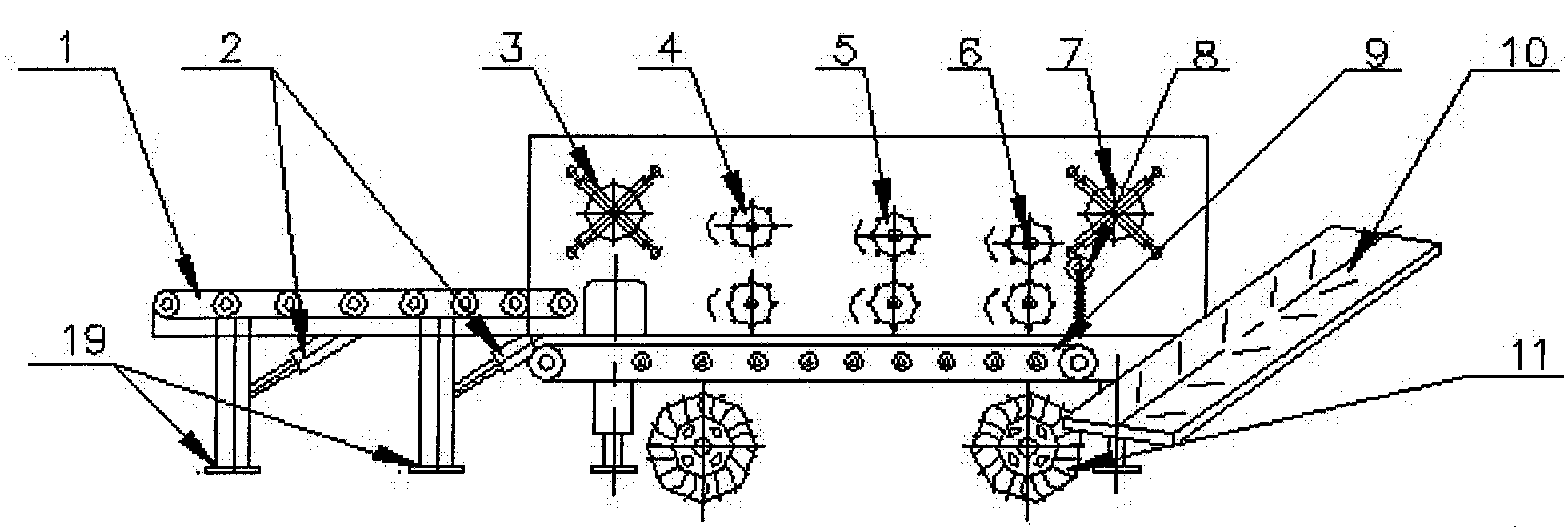

[0014] Such as figure 1 , figure 2 As shown, a utility pole pulverizer, the key is: comprise support 23, and the front end of support 23 is provided with four utility pole conveying frame supports 19 and the utility pole conveying frame 1 supported on described four utility pole conveying frame supports 19, Below each utility pole conveying frame support 19 is provided with a support retractable cylinder 2; four corners of the bottom of the support 23 are symmetrically provided with four mechanical hydraulic supports 12 and four tires 11, wherein the tires 11 are located on the inner side of the mechanical hydraulic supports 12 , the rear end of the bracket 23 is provided with a mechanical trailer frame 13 for conveniently towing away the equipment, the scrap conveyor belt A9 and the scrap conveyor belt B10 are arranged under the bracket 23, and the scrap conveyor belt A9 and the scrap conveyor belt B10 are provided with scrap The lifting cylinder 14 of the conveying frame a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com