Sectional type tire

A segmented, tire technology, applied in the direction of segmented casing, can solve the problems of high maintenance and replacement tires, and the storage space of the spare tire occupies a large space, and achieves the effect of simple design, great practicability and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

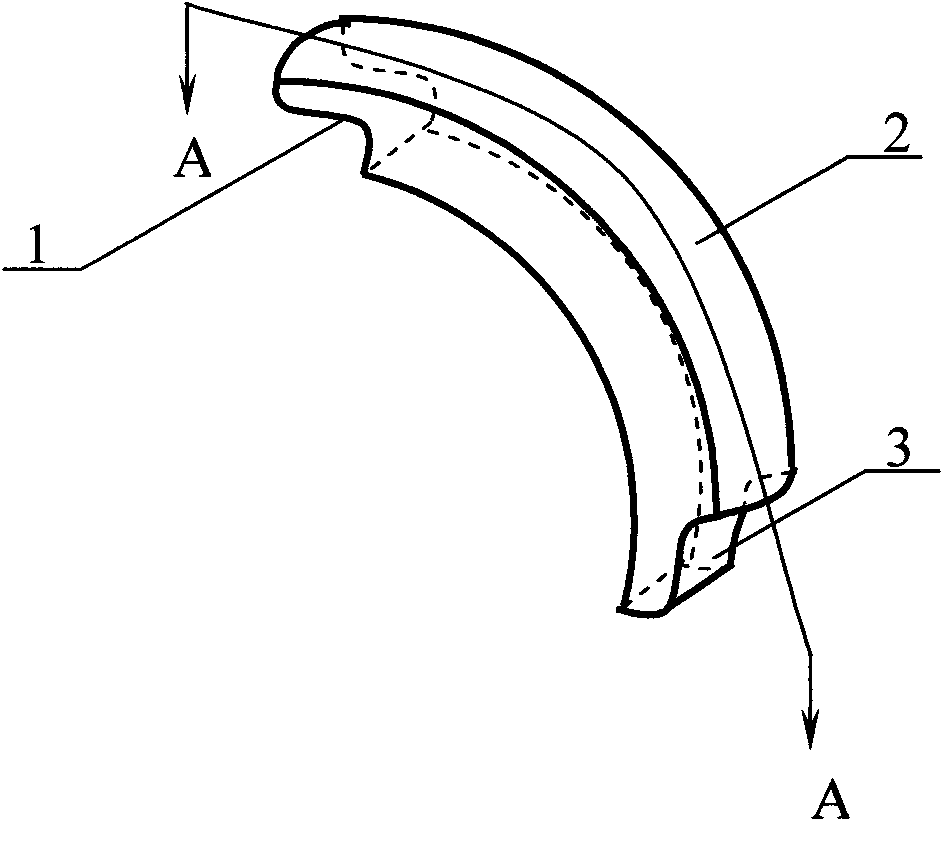

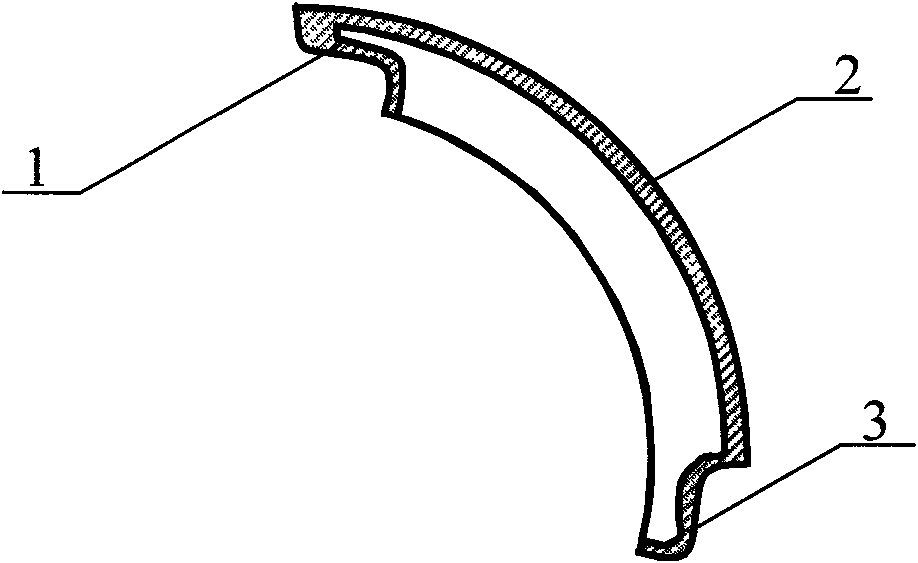

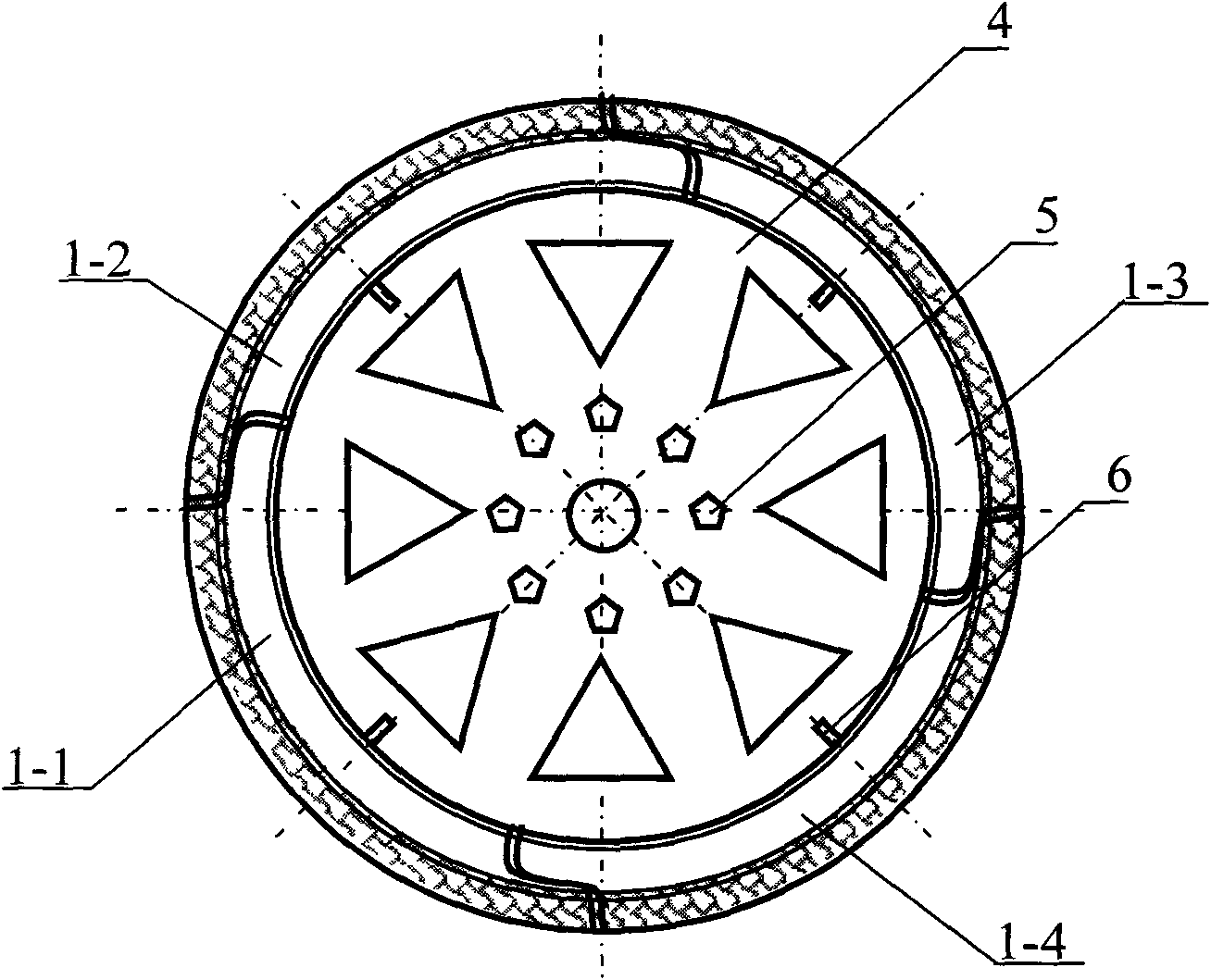

[0013] The present invention is composed of a boss 1, a carcass 2 and a recess 3, and is characterized in that the carcass 2 is an arc length of 1 / 4 of the circumference, the front end of the carcass 2 has a boss 1, and the rear end of the carcass 2 has a recess 3. The structure of the carcass 2 is produced according to the structure of the known technology radial tire. When using, the first section of the carcass 1-1, the second section of the carcass 1-2, the third section of the carcass 1-3 and the fourth section of the tire The body 1-4 is installed end to end on the wheel hub 4, the boss 1 of the latter section presses the concave platform 3 of the previous section, and is inflated from the inflation port respectively to form a complete circumferential tire. When one section is severely worn or broken, It only needs to replace the section of tire, so as to achieve the purpose of saving resources and reducing waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com