Aluminum foil indentation pattern rolling device used in cigarette packing machine

A technology of aluminum foil paper and packaging machine, which is applied in the direction of packaging, etc. It can solve the problems that the adjustment amount of the eccentric roller cannot be accurately calculated, affects the positioning of the brush, and the adjustment amount is small, so as to solve the problem of reduced effective operation rate, convenient adjustment process, and adjustment range big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

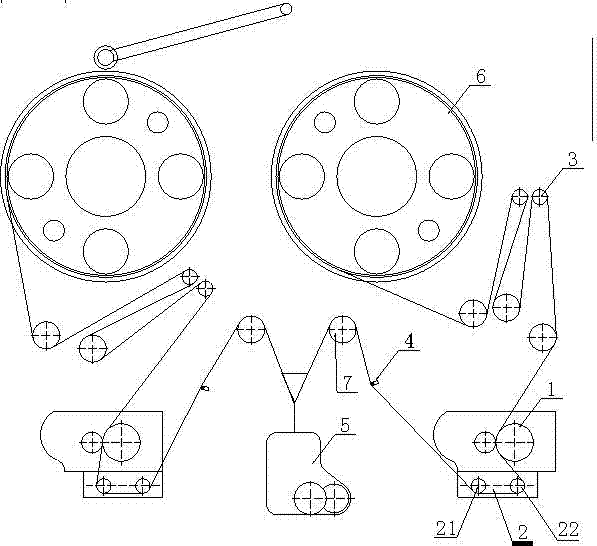

[0018] Such as figure 1 The shown device for embossing cigarette emblems on aluminum foil in a cigarette packaging machine includes an embossing roller 1, a fine-tuning device 2, a rotating roller 3, a brush 4, a reversing roller 7, a cutter holder 5 and a paper disc 6 , the aluminum foil paper is drawn from the disc paper 6, passes through a plurality of rotating rollers 3, and enters the embossing roller 1, the fine-tuning device 2 is arranged below the embossing roller 1, and the aluminum foil paper enters the fine-tuning device 2 after passing through the embossing roller 1 The reversing roller 7 is arranged above the fine-tuning device 2, the brush 4 is arranged above the aluminum foil between the reversing roller 7 and the fine-tuning device 2, and the paper cutter holder 5 is arranged under the reversing roller 7 After the aluminum foil paper goes out of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com