Dry distillation, reversal combustion and normal combustion integrated biomass combustion method and device

A biomass fuel and biomass technology, applied in the direction of solid fuel combustion, combustion equipment, lighting and heating equipment, etc., can solve the problems of insufficient combustion of biomass fuel, high ash content, and environmental pollution of pollutants, and achieve reduction Insufficient use, the effect of reducing the generation of ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the present invention will be described in detail below with reference to the accompanying drawings.

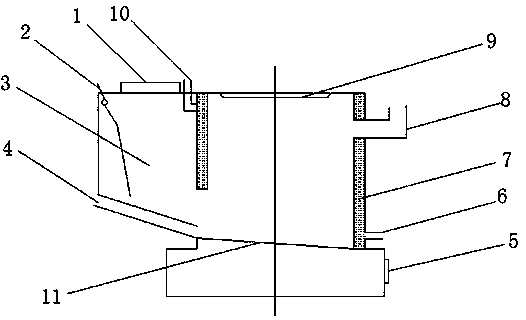

[0022] According to the drawings, 1 is the back-burning feeding port, and the biomass fuel entered through it is back-burning at the grate; 2 is the pusher rod, which is used to push the biomass fuel; Fuel is added at the row, and it can be used to preheat biomass fuel at the same time. 4 is the ventilation channel, located at the lower part of the feeding box, 5 is the ash collection box, 6 is the water inlet, 7 is the water jacket of the furnace body, located around the furnace body, and 8 is the Flue, 9 is furnace body feed opening, 10 is water outlet, and 11 is oblique combustion fire grate, carries out anti-burning at the top, and carries out normal combustion at the bottom.

[0023] The biomass combustion device integrating dry distillation, reverse combustion and normal combustion of the present invention mainly includes a furnace body and a feeding ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com